Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

re: “FRENCHIE”.

All my puzzle dimensions are driven by the thickness of material I use which is normally 3mm or 6mm. With a lot of my models, the size is immaterial and the files can be provided in vector images which can be resized without loss of definition. However If they have to be resized, it is by factor of 3mm or 6mm converted to your base especially where parts interlock, the gaps for the links has to be the thickness of the material. If I upscale to approx 1", I use 4 layers of 6mm MDF which means I would have to leave 24mm "mortices/gaps". I get thickness from laminating 3mm or 6mm MDF usin dowel alignment holes to prevent (usually minimise) slipage during glue-up.

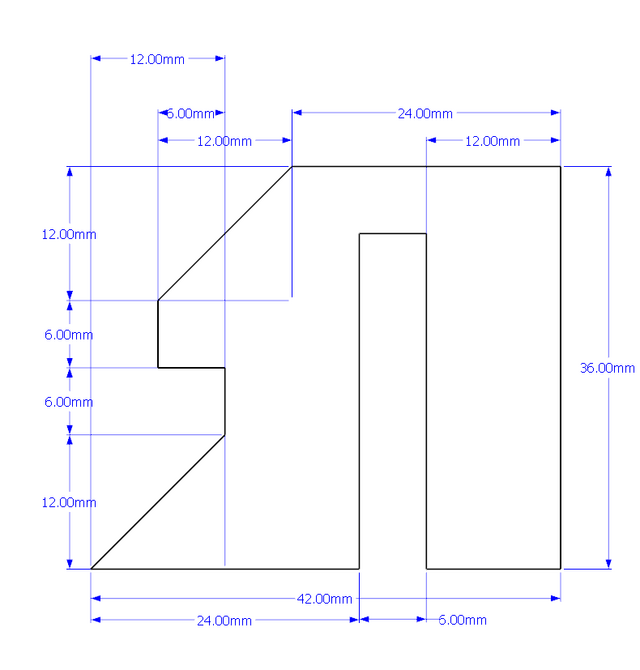

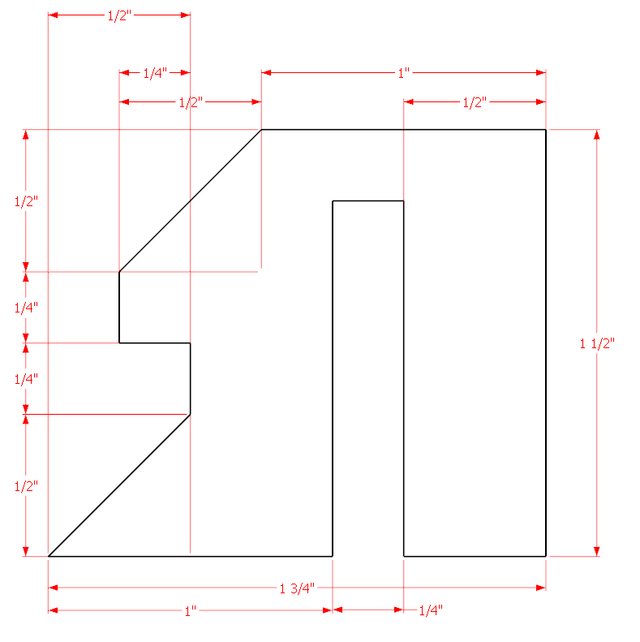

When I resize a model for imperial conversion, I need to increase so the 6mm gap is now 1/4" (or whatever your nominal thickness) by what would be a factor of 1.0583. This puzzle would be as follows for 6mm and 1/4" respectively,

When I resize a model for imperial conversion, I need to increase so the 6mm gap is now 1/4" (or whatever your nominal thickness) by what would be a factor of 1.0583. This puzzle would be as follows for 6mm and 1/4" respectively,

If your first cut is too short... Take the second cut from the longer end... LBD