Foghorn

in about 3 years

Drilling Holes in Dowel ends

Darrel

39 Replies

Thinking about what I have handy, perhaps a holding jig that has a 2" hole drilled into a series of 2x4 cutoffs, restacked high enough to support the Dowels (maybe 8"?). Could also drill larger for a sleeve of some 2" ID pipe (PVC) or just hole a top and bottom plate and form a box.

Maybe better would be the above box, cut in half through the holes. This would allow leaving the back half clamped to the DP table. You could then easily add/remove dowels with out the chuck getting in the way. Add dowel, replace other side of box to clamp it in place.

Of course it seems a lathe has the best potential for accurate hole location.

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Drill a hole the size of the dowel in a block but not all the way through. Without moving the block, then drill a 3/8" hole in the center of the larger hole. If you use a forstner bit for the larger hole, You can use the center point as a guide to drill the through hole and as long as you are careful and keep the drill square, the jig can be made entirely with a hand held drill. Put this block over the dowel and use the 3/8" hole to guide the hand held drill.

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Now your second post is the real "duh!" moment. Simple, accurate, easy, no-brainer, (shall I go on?). Perfect!

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Darrel

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

I agree Tony. I have a Taig lathe which is a bit small!

Darrel

Darrel

Foggy, you are talking to the boys and not SWMBO... buy that bigger lathe or at least a chuck/cole-jaws that will fit.

Now if I loaned you my bigger lathe and all my chucks, I'd probably have to try this way,

along with a prayer to the wood nymphs.

I would be drilling with a 9.525mm Viking Norseman Vortex Point Step Drill Bits (to be reviewed so I'm leaving the links/close-ups to 'ron).

If your first cut is too short... Take the second cut from the longer end... LBD

Drill a hole the size of the dowel in a block but not all the way through. Without moving the block, then drill a 3/8" hole in the center of the larger hole. If you use a forstner bit for the larger hole, You can use the center point as a guide to drill the through hole and as long as you are careful and keep the drill square, the jig can be made entirely with a hand held drill. Put this block over the dowel and use the 3/8" hole to guide the hand held drill.

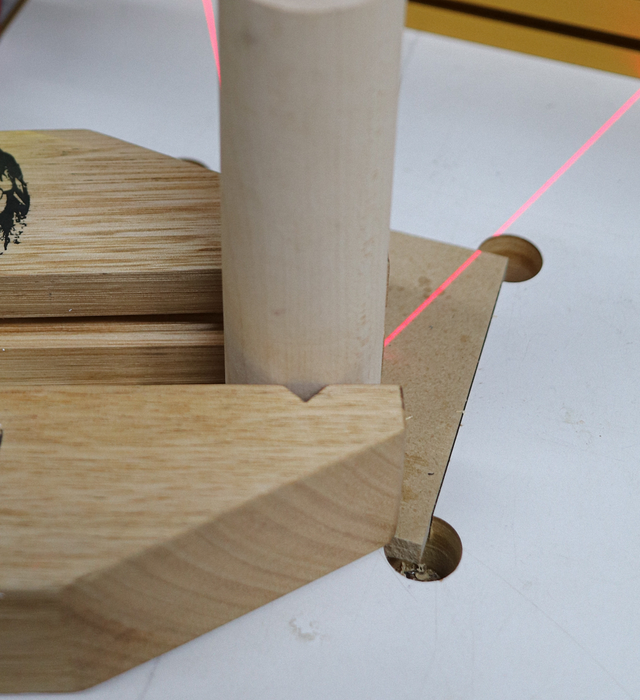

That's exactly what came to my mind as well, since I have these for smaller dowels

MosquitoMade.com

Darrel

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

If your first cut is too short... Take the second cut from the longer end... LBD