Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Rich

1300 posts

and

29 followers

in over 3 years

in over 3 years

Review: Festool Angle Stop and Guide Extension

Festool Angle Stop FS-WA and Guide Extension FS-WA-VL

I originally got the TSO GRS-16 guide back when I bought my track saw. At the time, the Festool offering was weak, and the Woodpecker was $$$$$, so I got the TSO so I’d have some way of cutting square until something else came along.

It did come along recently. It’s the Festool Angle Stop. I mentioned the previous offering from Festool was weak. It lacked indents for common angles—even 90º—and required you to eyeball the setting. Plus it was all-round flimsier.

I’m extremely impressed by the design and construction of this guide.

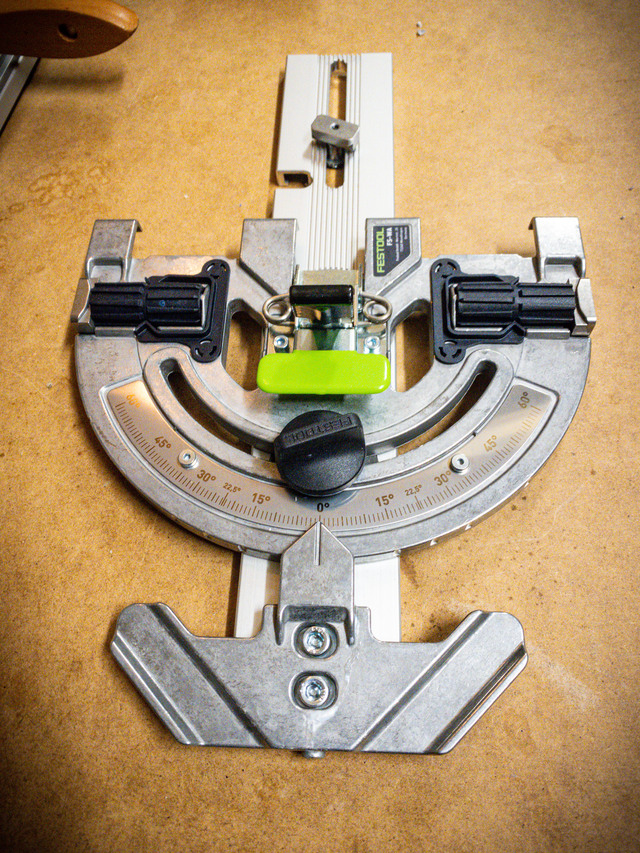

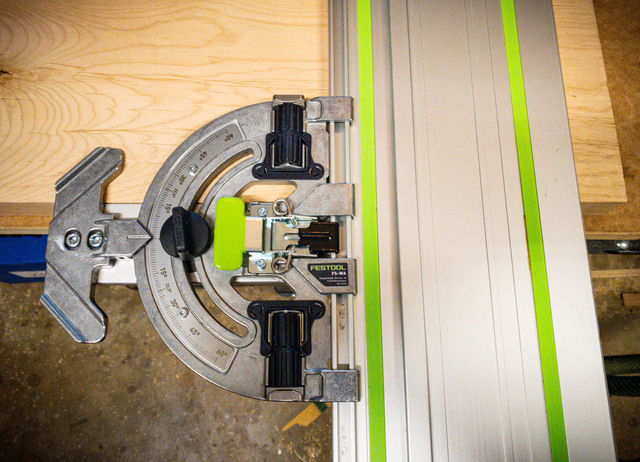

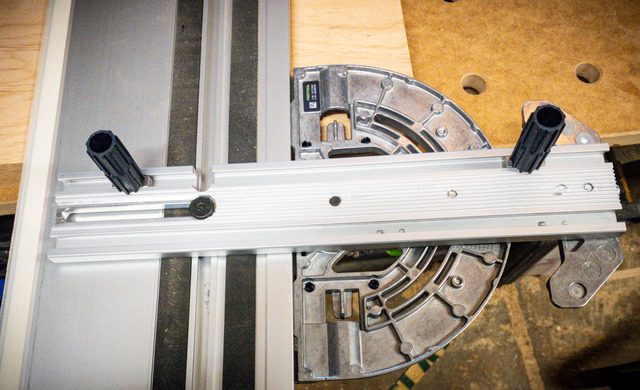

It attaches securely to the rail. The fence underneath aligns it with the edge of the board. The black pieces you see will be explained later. Those two angle slots on the back end are to accommodate clamps if you need them.

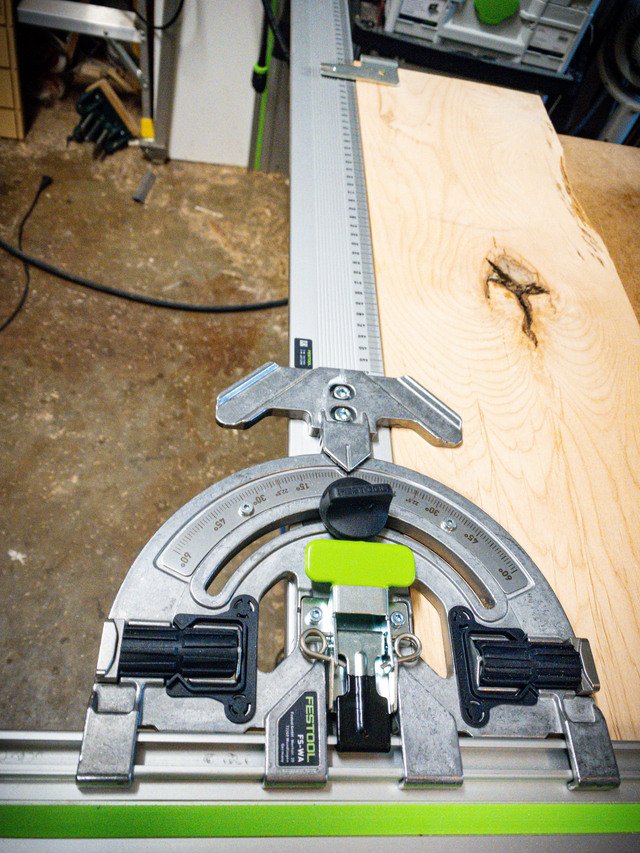

Here it is with the optional extension attached. It can be set to cut exact lengths using the stop.

The extension is marked in metric. I’m OK with that. I just pull out my calculator.

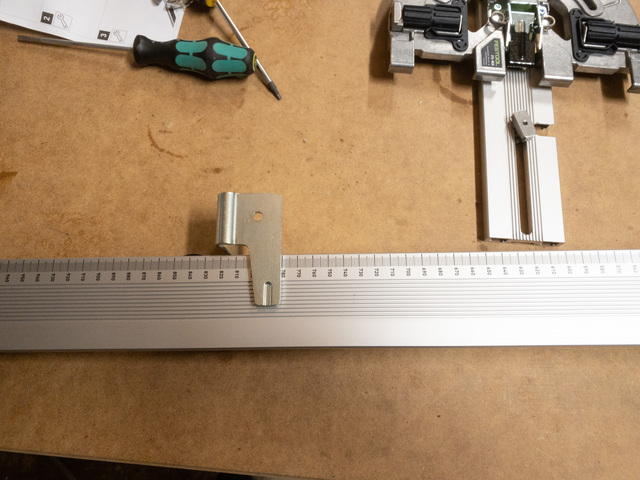

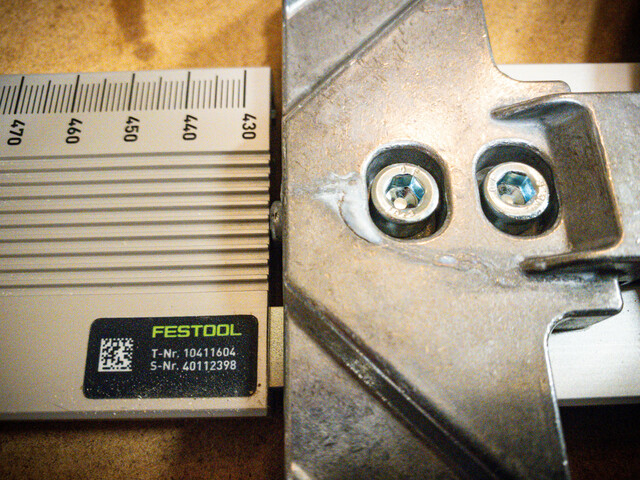

Here’s a close-up of the extension attached to the angle guide. The calibration is achieved by turning that little screw you can barely see between the two pieces. The white goo is some CA glue that ran. I’ll explain later.

This is the screw mentioned above. It acts as an adjustable stop allowing the two pieces to be calibrated. It’s pretty simple, you set the stop on the extension for a known length, then measure it with a ruler to the edge of the splinter guard. One warning on that is that unless that splinter guard is pretty fresh, it’s likely to be worn a bit. To account for that, I did a test cut and measured the result. Then adjusted the screw in or out to get the cut exact.

BTW, I used the CA glue as lock-tite. It has something on there to start with, but I didn’t think it held tight enough.

Finally, this a look at the underside. The two black pieces are intended for times when the fence won’t make solid contact with the edge of the workpiece, like if it’s been rounded over. They store conveniently as shown in the top image.

The notch you see along the t-slot in the track is to allow a clamp to be used if needed.

Half of what we read or hear about finishing is right. We just don’t know which half! — Bob Flexner

1 Reply

Rich, I have to check that out.

Thanks for posting

Thanks for posting

Petey