Eric - the "Loft"

in over 3 years

More from Eric - the "Loft"

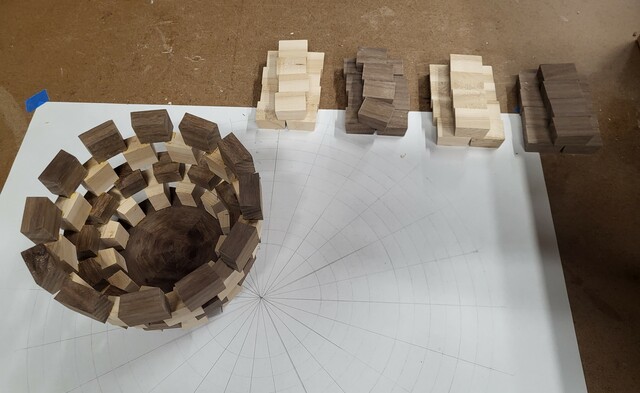

Open Segment Bowl

I started with a base, chucked up on the lathe and turned the tenon on the bottom. That worked out well, so I could chuck it up later after the rings were glued up. Then started to glue the rings on to the base, took a compass and marked the interior of the ring, then using a full scale drawing of circles divided off for 24 segments, (a few were off a bit). Then placed a gallon paint can on top for clamping pressure. (I need a real jig before I attempt the next one, have an idea for that). Before gluing the next level, I took a Xacto knife and cleaned up the excess glue from the joints, placed the blank in the chuck and sanded the surface flat, rinse and repeat to the top. Then glued on the top ring which was glued up using hose clamps. (The wedgie sled I build a while back worked like a charm)

After everything had set a bit, I chucked it up on the lathe, it was a little out of balance. I placed a piece of plywood on the tail stock (with a live center) to support the blank while turning the exterior. I bit scarry turning with the openings, very gentle touch.

After the outside was turned down, off to the inside. Note: the balance was better now. I started at the edge of the bowl and worked my way in. Started getting a little rough turning, so I started going from the bottom to the lip. Nice thing about turning an open segment is the chips fall out and don't build up inside.

After I was happy with the shape inside and out, plus did not want to get to thin. (It turned out to be just over 1/4") Left in the chuck and using a fine file cleaned any remaining spots of glue from the segments. I finished this with Danish Oil (had to use a brush to ensure I sealed the end grain of the segments). Then placed it back on the lathe and buffed, with a few coats of Howard's Feed and Wax.

Overall, happy with the outcome, and will try this again down the road. Maybe with some patterns.

Thanks for looking and comments are always welcome and appreciated.

Main Street to the Mountains

24 Comments

Ron

Corelz, thanks. I am liking these kinds of turnings, less wood.

Main Street to the Mountains

My layout for glue up.

And stacks of wedges.

And that wedgie sled.

Main Street to the Mountains

Nicely done!

May you have the day you deserve!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

No name noobie here

...woodicted

-- Soli Deo gloria! ( To God alone be the Glory)

Ryan, thanks. looking forward to see what you come up with, you need a good jig for the glue up. I am working out a design for a shop built one.

Yrti, thanks. Time consuming process, but the results are well worth it.

Ivan, thanks. There are the challenges, but overall fun.

OldTool, thanks. I look for more interesting projects that are a little out there.

Mike, thanks. Yes, it was a bit scarry to turn, slow and gentle process.

OldRivers, thanks. Fun project, maybe inspire more.

Side note: BlockLayer.com has a good segment calculator, for both wedges and staves.

Main Street to the Mountains

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Main Street to the Mountains

Looks great. Not a turner yet, but maybe someday.

daveg, SW Washington & AZ

Main Street to the Mountains

Main Street to the Mountains

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Main Street to the Mountains