RyanGi

in over 3 years

Drill Bit options…

What type and mfg do you have a prefer, and for what reasons?? I’m certainly no aficionado, but I’ve ruined my fair share of bits! I’ll rely on you experts to point towards better value bits, or your favorite high end bits.

I’ve got a set of chineseum forstner bits that work pretty well actually. I never thought I’d use them as much as I do, so I bought a more budget set. I’d really like to upgrade them to a complete set of Fisch wave bits since I do use them quite a bit. The ones I have aren’t hard to sharpen with a diamond card and a slip stone.

I’ve also got a partial set of brad point bits that I used regularly. I think they’re Fuller, but I’m really not sure. I far prefer brad point bits to twist bits, since they center so much better. I also bought a cheap set of 12” brad points for use on the lathe (chineseum). I’ve got bit extenders for that, but the lug at the end means anything with a cutting diameter of less than 3/4” can’t be used. Not that you generally need 12” long 1/4” wide holes but, by the time I chuck up a regular, smaller brad point on the tail stock there might only be 2” of length left (or less!). It’s nice to have just a bit more.

Of course I’ve got a set of big box store twist bits (from the red vendor) that are just for regular stuff, but I honestly almost only use the brad points anymore.

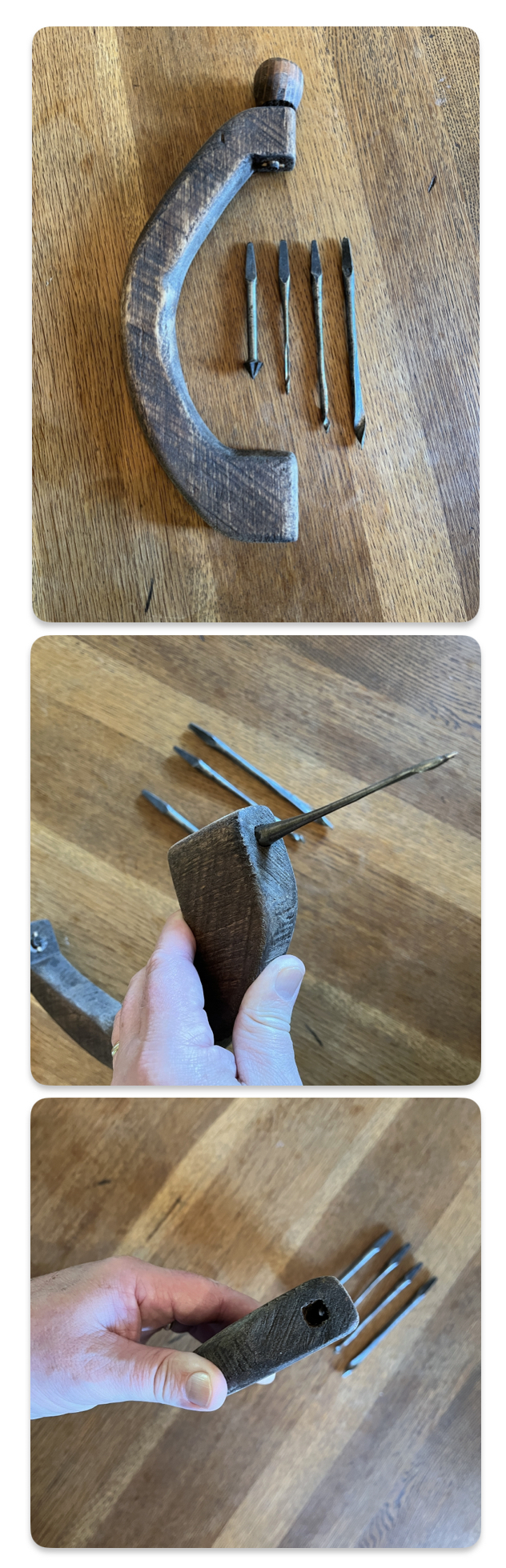

I’ve also got an antique set of hand brace auger bits, but I don’t know who the mfg is. They’re good quality steel and a full rack, 4-16. They’re pretty easy to keep sharp and, while some folks who haven’t used them might think it’s the slow way to go, it’s actually amazing how quickly and cleanly they cut on a hand brace. The trick, just like with forstner bits, is that they cut best at the slow speeds of a hand brace. I had one with a worn out worm (the threaded tip at the end) and that also makes a huge difference in how well they cut, at least at the start. If you’ve convinced yourself you don’t need a hand brace and bit set, renthink it! They can be had for a very reasonable price on eBay and are a great addition.

Lastly, on the metal side, I’ve got a complete index of carbide twists bits. Most woodworkers don’t need them, but having the complete set (letters and number) makes a huge difference for metal work. I use them more than I thought I would! I also bought a (fairly) complete set of machinist’s twist bits. For anyone who might be unaware, machinist’s bits are extra short and stubby so they flex less. Not an issue in wood usually, but it is in metal. I also have a small set of under and over-sized reamers. These are needed to make a press fit or slip fit hole, again for metalwork.

All of my metal bits are chineseum, because I just don’t use them enough to justify spending more.

So what do you have and why??? And which mrg do you like best?

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

67 Replies

I also have a set of number bits (1-60) when I need to properly size a hole.

Wood bits? I've given up on the really cheap Chinese Forstner bits, though I did buy a set of metric for the +/- capability over the inch sizes. Beyond that they dull very quickly. The ultra cheaps are good for custom stuff like when I needed a flat bottom hole for a magnet and wanted to get as close as possible to the outside face without punching through. Drill a starter, grind the pilot spur off the cheap bit and finish the pit.

Probably more "upscale" Chinese are a set of TiN coated "Columba" Forstner bits that have done well.

Forstner bits give me the flat bottom holes I need regularly and if I make a small centering hole (1/16") the Forstners do well to center on the pilot. I just touch the point and let the workpiece move over, then hold and drill.

Brad points are great for clean entry edges and cut fast. I have a set of Fisch "Vortex-D" which are excellent, but I don't use them as much as the standard and Forstner.

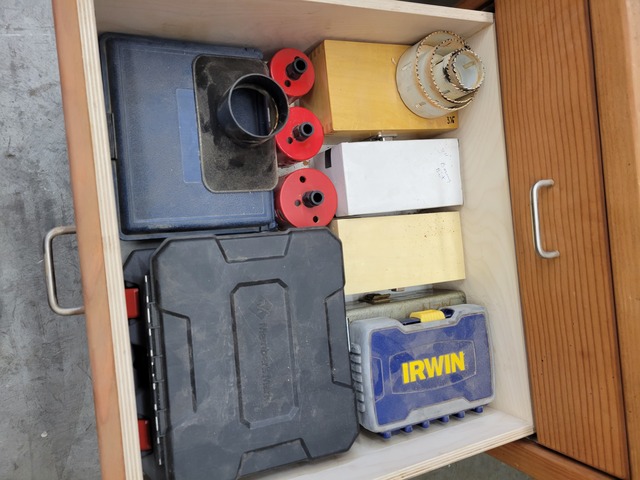

this top drawer under my drill press is auger bits, drill indexes and assorted bits. one index is hanson and one is irwin both ive had for many years. also have a set of crappy chinese steel bits i use when i know there gonna get destroyed. also a set of cobalt bits made by dewalt.

the drawer under that one is hole saws and plug cutters. hole saws are an old set of blu mol and ive recently got a set of freud diablo carbide bits that have a quick change arbor that works very well. plug cutters are all fuller,work very well making clean plugs in soft or hardwoods. also have a full set of brad bits which are my go to for most needs made by fisch.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Great idea for a thread! I have more drill bits and apparatus than I care to admit. I have a chinese metal lathe and have tons of bits that I use on it, from a full set of Deming bits, a full set of fast relief bits, a full set of TiN numbered, lettered, and fractional all kept in the cabinet the lathe is on with 12 different drill chucks in MT 2, 3 ,and 4.

For wood working I have several sets of Forstner and many, many specialized sized forstner up to 4". I have even bought two sets of the 150 replacement bits ( forgot I had one and bought another), hole saw sets both regular and bi-metal, several spade sets, many step bits, glass bits, masonry, airplane bits (the real long ones), the hardened bits for drilling hardened steel and brad point. I have so many kinds of drills that I have a Kennedy cabinet, center and Craftsman roller bottom just dedicated to drill things. Plus I have several drawers in a low-boy machinist cabinet filled with bits I use for just pens. I love drill stuff.....

Mike

Never can have enough specialize bits. I have a wide variety of diamond bits for mostly my wife's glass stuff, but since I am their keeper, I get to use them when ever.

Hole saw/bits are a gripe of mine. They always get fried (mostly from my abuse). I'll need to start buying the carbide tipped units in the future.

For other types of bits, I have a mix. All my spoon bits are the Gramercy Tools ones. TFWW sells the Fisch Jennings-pattern auger bits, and I have those, but they don’t sell 11, 13, or 15/16, so I have vintage ones in those sizes. Fisch Wave bits for forstners, which work well. I’ve got a full set (to 20/16) of vintage Irwin augers, too. Probably a bunch I’m forgetting off the top of my head, too.

May you have the day you deserve!

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Knowing how to use a tool is more important than the tool in and of itself. - Ron Aylor

I picked up a Drill Doctor sharpener at a yard sales a couple of years ago. I have not used it very often but it actually works pretty well for fixing abused twist bits. It has breathed new life into some old dull bits. I use it so rarely that I takes me longer to re-read the instructions to refresh my memory about how it works than it does actually sharpening.

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Cheep Irwin forster bits. Not dull yet.

Many others collected along the way.

Good forum thanks

Petey

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Lazyman

replied about 4 hours ago

Forgot to mention that when you need a spade bit, the Irwin speed bore are the best I've used. Gotta be careful though because they self feed so you can tweak your wrist if you use them in an awkward position.

I have a mix of pretty much everything and most all of them are cheapos. I bought a 14 piece set of Bosch cobalt twist bits for drilling through hardened saw plate that work really well. Now I wish I had bought the 21 piece set for the in-between sizes.

"Duck and Bob would be out doin some farming with funny hats on." chrisstef

How about best value?

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

One thing that I am aggravated about is most of these sets go from 3/8" to 1/2" excluding a 7/16" size. I needed to drill some 7/16 holes in steel plate not long ago and had to go to the store to buy one bit.

"Duck and Bob would be out doin some farming with funny hats on." chrisstef

How about to someone who’s ready to upgrade to the buy-once/cry-once package?

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

For someone upgrading, buy the best you can afford, but not for something you will rarely use.

Most of my cheap stuff was bought when I didn't have much money. Now that I can afford better quality, that frugal mentality still seems to linger.

"Duck and Bob would be out doin some farming with funny hats on." chrisstef

Buying in sets gets you the volume discounts. If you go middle of the road in quality here you can replace the single worn-out bits with a better $/hole value.