BB1

in over 3 years

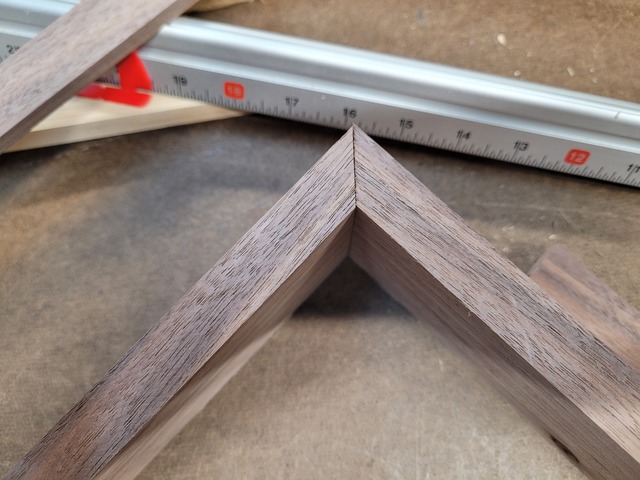

Flag case - issue with "gap"

I decided to go with at 45s which resulted in a "gap" in the back when I made the cut to hold the backer.

I am planning to "fill in" with a small piece. Thinking once sanded it will not be noticeable (especially on the back side).

Open to other suggestions!

Also want to create a base - not sure of my direction on that yet.

58 Replies

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Blade is best for a higher count (at least 60 tooth) crosscut blade. I try to use brand new ones when doing these. Sharp carbide is good, dull, not so much, and also pitch can create drag, so old blades can sometimes spoil the work.

Those are my 2 go to tips when cutting these.

For a fix, I'm with Larry, a thin shim, and carefully sand it down, and it will all but disappear.

Bases I also agree with Larry, let the flag do the talking.

One thing that really helped with the bevel cuts (I think that's the right terminology for 45s on an edge?) was to take a sled I wasn't using much and adjust it for bevels. The right panel can slide over (after I adjusted the opening for the knob).

Worked great and my joints seem tight. Hopefully will give a good glueup.

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Like Pottz and GeorgeWest, I think your planned fix is the way to go.

In your other thread (which I somehow missed), you mentioned adding a drawer. Are you thinking about integrating it into your base? The piece you showed is thick enough to accommodate one.

Ron

After much going back and forth in my mind, I decided against the drawer as it seemed like it would be so shallow as to not be of much benefit. I may build a separate shadow box if my nephew would like to display any items, or a nice box if he would like a special storage option.

Current status

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

I also think you made the right call about omitting the drawer. I think it would have unbalanced the design too much, making it too bottom-heavy and drawing attention away from what should be the focal point—the flag.

I appreciate the encouragement. Really want this to look nice.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

As for the base, if you oversize it a bit, consider leaving the back side flush to the flag case. Otherwise it ends up with a large open gap between the case and the wall when you set it on a table or in a cabinet. A little detail router work on the sides and leading edge of the base make for a nice contrast as well.

Not that I’d think you’d go this way, but I saw a beautiful case once, made of walnut, with an ogee cut along the oversized base. The ogee was painted black and gave a very stylish accent to the whole thing. I’m not usually a paint & clear finish kind of guy, but that one looked really nice.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ryan - thanks! I thought I had a base, but messed up the width as I measured using the case BEFORE I attached the face frame. Now if I offset the front, the base isn't supporting the back of the case (and I don't like it flush on the front).

Groan - my last section of that walnut too. 😟 I'm going to try a different design.

If I can't get a final product I like, I'll start over (not what I want to do!). The case part is coming along.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.