RyanGi

in over 3 years

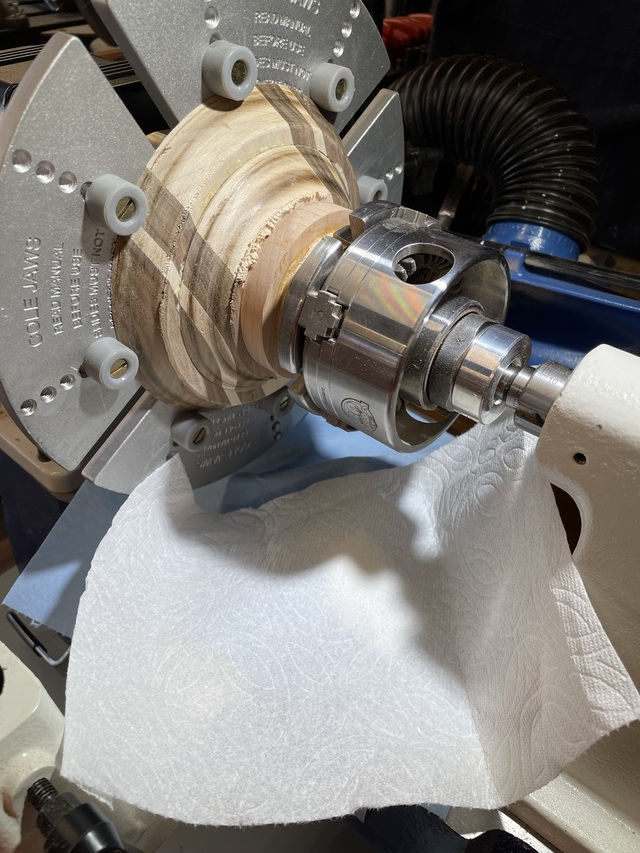

Bowl Turning trouble…

Anyway, I started to turn it, 24 hours after final glue up and it came apart at one of the seams. My inclination is that I simply did t use enough glue, so I’ve reassembled it with more titebond and it’s setting up now.

I’m using the lathe as a press to hold all the layers together during glue up (one layer at a time).

Anyone else had this happen? Am I missing something more fundamental than ‘more glue’. Any tips would be appreciated.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

59 Replies

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Found a photo, 1/4-20 all thread in the corners, bottom was double nutted then one just needs to tighten the wing nuts on top with even pressure

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

I flatten the wide end of each layer on the lathe, and the skinny end of the next layer on the stack is flat from when I made it.

You can see some voids and soft spots in there. On this one I wrapped the whole thing in blue tape and poured on a little more epoxy to fill the voids before attempting to turn it.

Might not be the “right” way, but it’s worked for me.

May you have the day you deserve!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Main Street to the Mountains

May you have the day you deserve!

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

And that ends our broadcast day…

Can’t win for losing with this bowl.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

May you have the day you deserve!