RyanGi

in over 3 years

Workbench of Your Dreams v2.0

I’ll start:

My bench was inherited from from Father in Law, it was his father’s, so it’s got a few years on it. But, it wasn’t a woodwork bench and was just more of a shop bench for him. I got it soon after I married my Father in Law’s daughter, since he thought I needed it for the garage. Over the years, as I got into woodworking, I doctor’d it up and tried some things I ended up liking…and hating. First, it’s only construction lumber thick (albeit ‘real’ 2x6s, they were laid flat…so only 2” thick top). I put a 3/4” thick solid wood panel on top of it (I’m guessing it’s pine by looking at it, but I don’t know…it’s not all that soft), and dadoed in some T-tracks for hold downs. I also built an extension off the left side, and tied that into a couple other coplaner height rolling tables. In the pics, you can see the T-track still on the side extension.

When using nothing but machine tools, this was ok, but once I started using hand tools in earnest, the tracks needed to go. Not a fan of any metal on the bench around open blades. So, I took out the T-tracks and filled the dadoes with wood strips, planed to match the height. Second, the bench had an old machinists vise atop it. I pulled that off (moved it to the other side of the shop where it still does awesome service), and put on a cheap face vise. I didn’t really know what I was doing, but it actually worked out ok. Eventually I wanted dog holes, so I added a bunch, which worked pretty ok in the now 2 3/4” top. Sometimes it takes an extra whack, but they hold fast! At about the same time I added a sliding deadman. Not perfect, but I did ok! I ran t-track along the face (unlike a proper woodworkers bench, the top overhangs the front stretcher like a proper table). To that I secured the deadman I made using two T-bolts and finger knobs. I made the deadman thick so it’s coplaner with the edge of the bench, as it should be for a deadman. Not long after that I added a Klein face vise. That certainly changed the game. I had to do some creative build up to make the chops function properly, but it worked out. Solid maple moving chop, but the stationary chop is pine, lined both sides with crubber. That vise is great to look at, but it’s just super functional too. I love it.

Not knowing what the hell I was doing when I started all this, I built the whole shop around having the bench up against a wall. Not ideal for hand tools, but at this point I’m not even sure how I’d redesign the shop to work with the bench in the middle. Regardless, it works well for me. The tool wall is in front and above, and I’ve got all the DeWalt 20v tools (plus some other stuff) stored below. Someday I’d really like to have a more proper woodworker’s bench, but this does ok for me…and it’s kinda hard to turn your nose up at a working bench three generations old! I bet, when I do build a proper bench, I’ll scavenge at least one of the parts from this one so it’ll live on.

Tell me about your bench!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

15 Replies

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Darrel

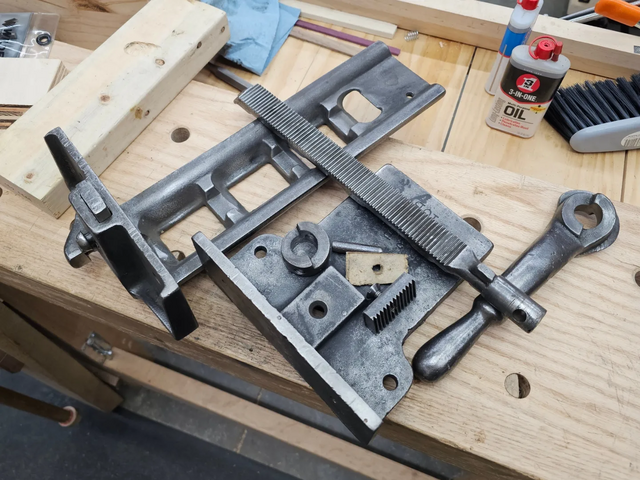

I'm in the planning stages for a new bench to put this vise I restored on. Also, I may have bought a second one too, but a screw version of it with speed handle. I may have a vise vice...

MosquitoMade.com

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

MosquitoMade.com

MosquitoMade.com

I sliced off the bottom, drilled some holes and then turn some tenons on some cedar branches that I had laying around and sliced the the top off.

You've heard of a saw horse or even a saw buck but how about a saw pig?

It was fine as a proof of concept but it was just tool low so I sawed some longer legs out of some live oak also laying on my driveway, sliced the belly off the pig and made something a little more useful.

Nothing fancy but it will save my back and knees from stooping and kneeling.

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".