Rich

in over 3 years

More from Rich

Festool Domino Cradle for Surprise Swap 2023

I didn't come up with the concept. Ramon Valdez, a very talented woodworker and tool maker from New Mexico had the original idea as far as I know. Rather than try to reinvent the wheel, I simply decided to copy his basic design. I did make quite a few enhancements along the way by smoothing out the lines and eliminating some screws that detracted from the appearance. Functionally, however, the cradle performs the same as the original.

At the end of the day, it's just a jig. While plywood would do the job as well as anything, for the swap I wanted to make it nicer. I found a nicely grained piece of padauk at the store and decided it would be jazzy enough for a swap.

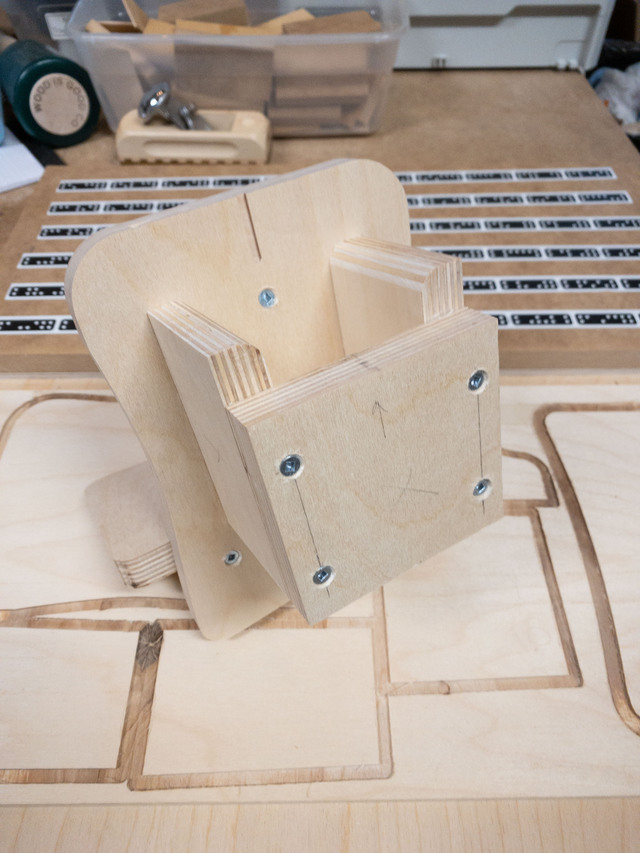

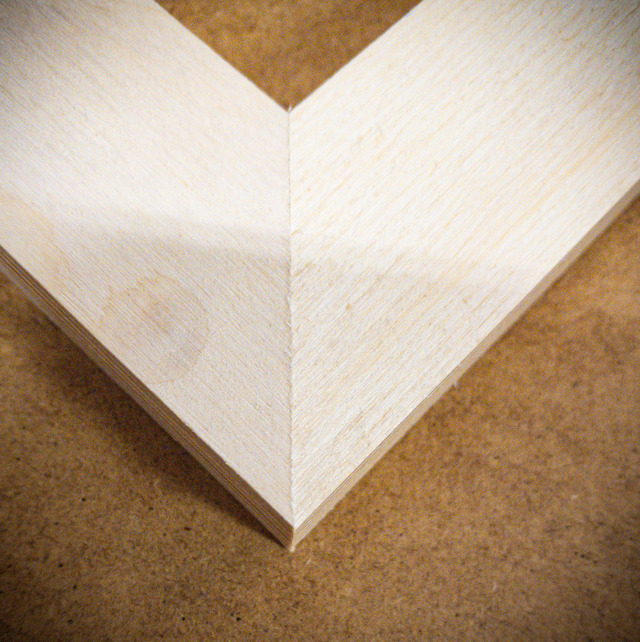

Here's the prototype. I cut the pieces for it from 3/4" birch ply using the Shaper Origin. My second version was hardwood and I cut plugs to cover the screw holes. That worked well, but I didn't like the look on the front plate. The plugs were visible enough to bother me.

That's when I came up with the idea to use the prototype cradle with the Domino and attach the front plate to the side pieces with dominos. It worked perfectly and had the added benefit of ensuring the parts were perfectly aligned when I glued them together.

Rather than cut the 3/4" hardwood completely with the Origin, I decided to make templates and use a flush trim bit. That's less wear and tear on the Origin, and produces smoother results.

I posted this before, but here is one of the pieces after flush trimming. Look carefully and you'll see that I dared to go up-grain on that curve. A regular two-flute bit would have shot the wood across the room, but the Whiteside compression bit with its large diameter and 45º shear didn't even flinch. (BTW, that wasn't necessary and truthfully wasn't very smart, so I would recommend putting the template on the other side and going with the grain for a safer cut).

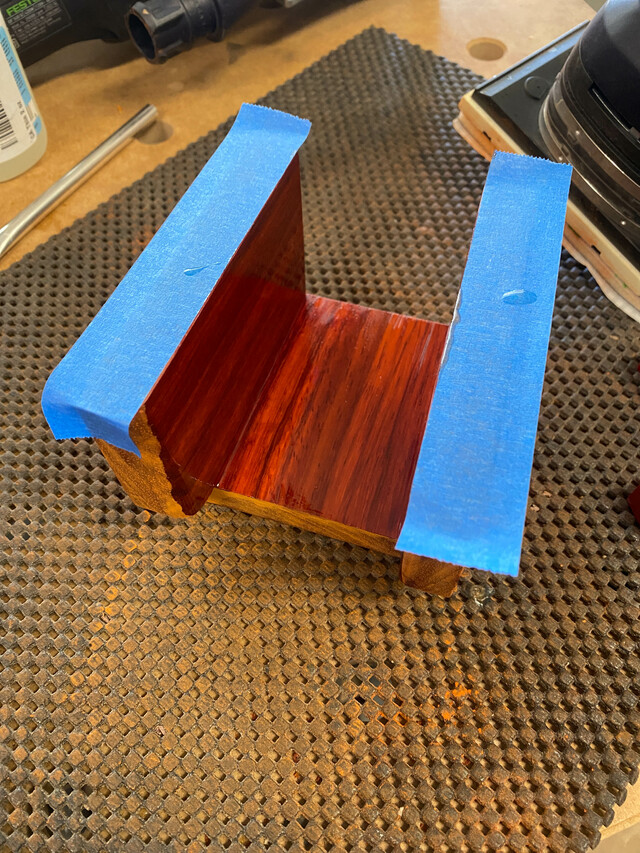

I used Odie's Super Duper followed by regular Odie's oil for a finish. Here, I wanted to get the inside of the box finished before attaching it to the main plate.

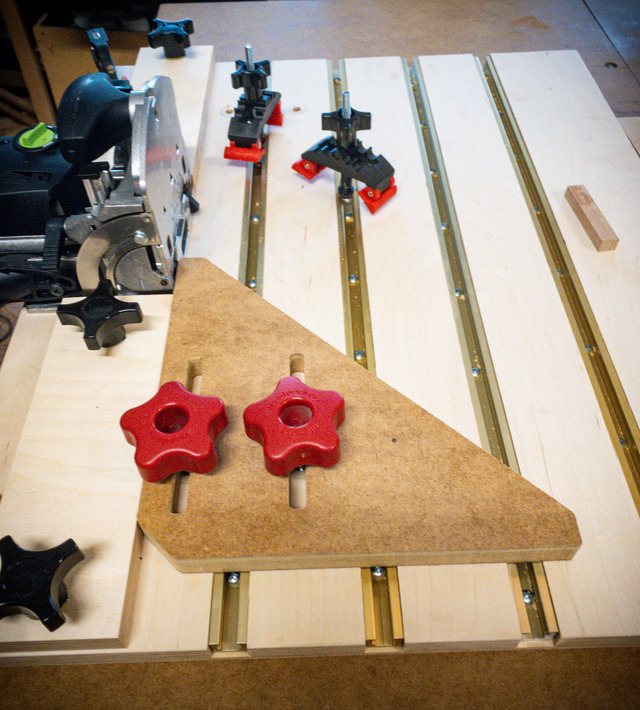

I'm working on a seminar where the Origin is used to cut the pieces and the cradle is assembled and ready to take home. Here are some templates to speed up the process and reduce the risk of error.

The first one is to mark the screw positions for the screws that hold the box to the main plate.

I created this fixture by flipping the design and used the Origin to hog out the fixture so that the main plate locks nicely in place.

It is then used to align the box on the main plate. Sorry no photo of that.

The three holes are used to mark the screw locations that attach the clamp plate to the back side of the main plate.

Again, no photo, but the entire package is flipped over and the 5mm bolts inserted in the 5mm holes align the clamping plate perfectly. No marking or measuring needed in any of this.

I've never used padauk before. It mills beautifully, smells nice, but sure does make a mess. I still have orange stained stuff out in the shop.

Once I saw what it looked like with Odie's I was sold. It's amazing what it does to the color and depth.

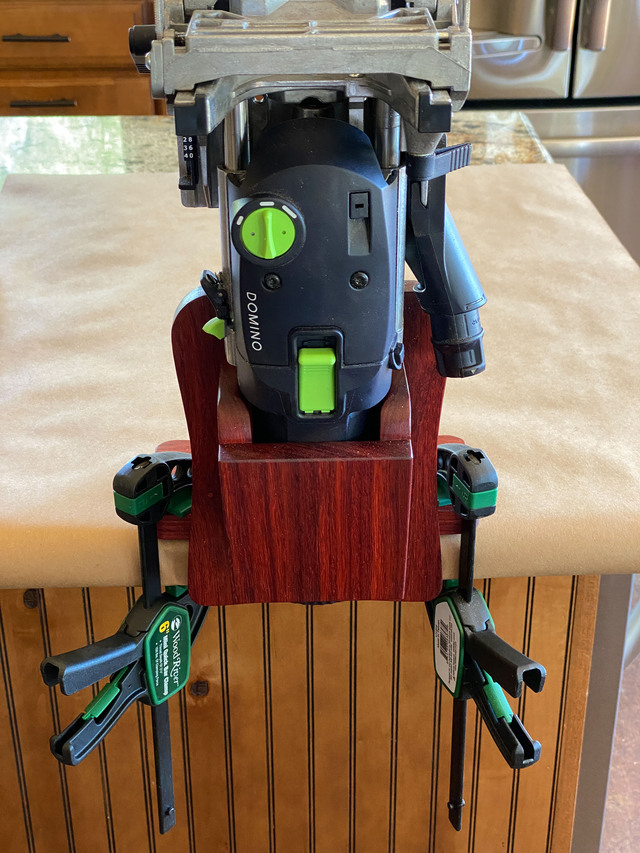

Here's a test fit on Ryan's cradle. Snug as a bug in a rug.

The rest of the photos are just different angles.

Half of what we read or hear about finishing is right. We just don’t know which half! — Bob Flexner

25 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Half of what we read or hear about finishing is right. We just don’t know which half! — Bob Flexner

Main Street to the Mountains

The Other Steven

Half of what we read or hear about finishing is right. We just don’t know which half! — Bob Flexner

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Petey

Ron

now join next one you know your addicted now 🤣🍺

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Tony, it was fun, but you guys are way out of my league on creativity and execution. I think being a member of the audience suits me better. I do love the swaps and the banter that accompanies them.

Half of what we read or hear about finishing is right. We just don’t know which half! — Bob Flexner

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Main Street to the Mountains

"Duck and Bob would be out doin some farming with funny hats on." chrisstef

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

I'll be taking another look at improvements for Version 2 in the future. For now the prototype does the job.

Half of what we read or hear about finishing is right. We just don’t know which half! — Bob Flexner