Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Dutchy

1584 posts

and

60 followers

in over 11 years

in over 11 years

More from Dutchy

Router table extension.

I use multiple roundings during a project to make models. After milling a length of 50 cm, it is sometimes necessary to switch to a different profile. In short, the exchange takes considerably more time than the actual milling.

It has been twenty years since I saw a router table with 5 router units at a yacht builder. These milling motors were brought into position with pneumatics. This way they could always choose from 5 fixed profiles. Even then a precious machine and too precious for what I do with it, but I have never forgotten it since.

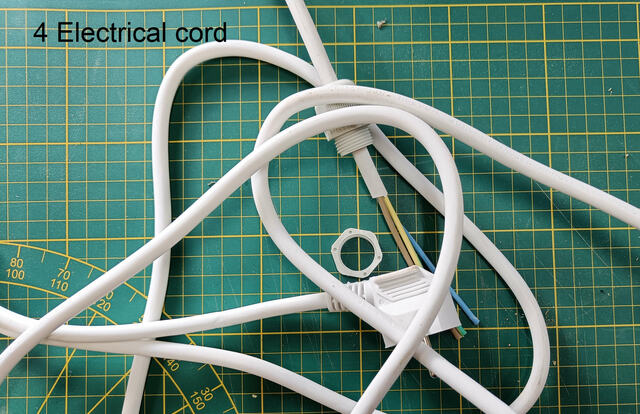

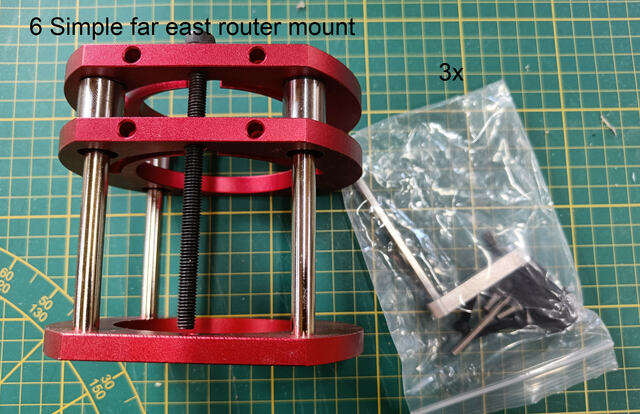

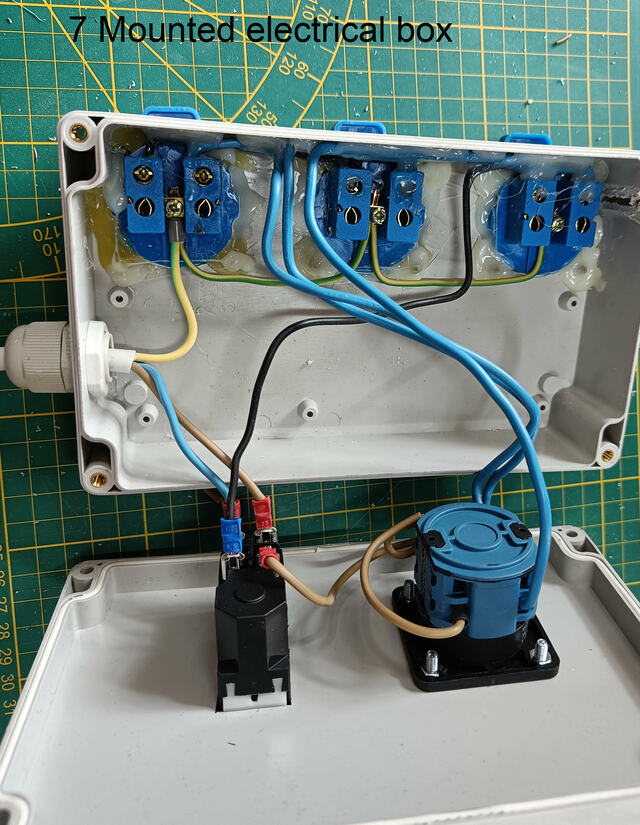

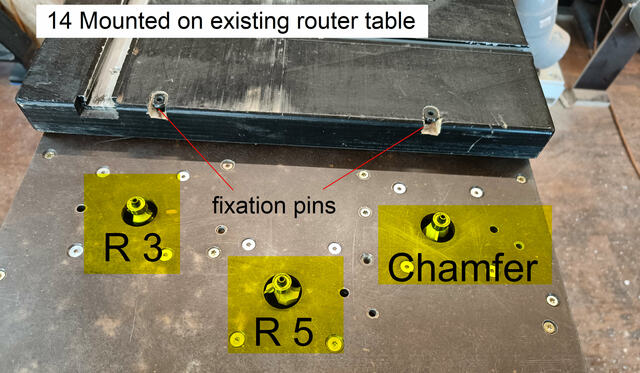

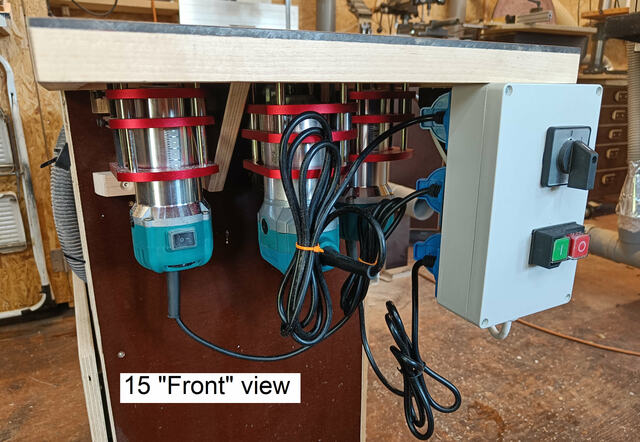

I chose to buy three inexpensive milling machines and router lifts. They doesn't define great quality, but for my purpose it is sufficient. I also had to buy some switches and wiring, which are mounted in a box (There can never be more than one machine working). This way I can choose from three profiles that are actually always ready for use , for now chamfering, rounding R3 and R5. For clarity, all three always remain at the correct working height.

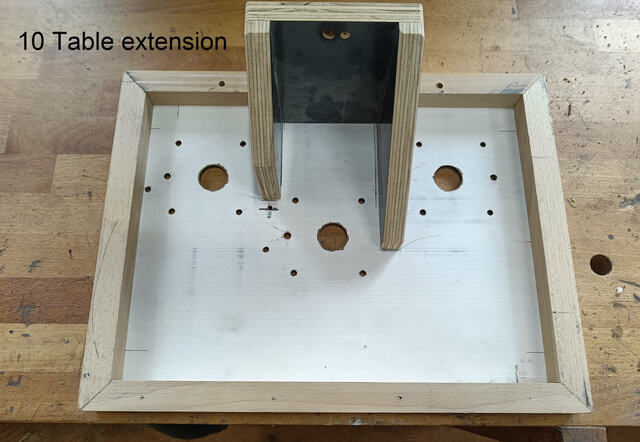

For the table itself I used Trespa (high-pressure laminate) and beech. The total cost of the whole is less than € 220. The extension can also remain in place when using the standard router table without being affected, this means that there are four profiles available.

I hope the pictures below make it clear how it works, but questions and comments are allowed.

Thanks for watching.

It has been twenty years since I saw a router table with 5 router units at a yacht builder. These milling motors were brought into position with pneumatics. This way they could always choose from 5 fixed profiles. Even then a precious machine and too precious for what I do with it, but I have never forgotten it since.

I chose to buy three inexpensive milling machines and router lifts. They doesn't define great quality, but for my purpose it is sufficient. I also had to buy some switches and wiring, which are mounted in a box (There can never be more than one machine working). This way I can choose from three profiles that are actually always ready for use , for now chamfering, rounding R3 and R5. For clarity, all three always remain at the correct working height.

For the table itself I used Trespa (high-pressure laminate) and beech. The total cost of the whole is less than € 220. The extension can also remain in place when using the standard router table without being affected, this means that there are four profiles available.

I hope the pictures below make it clear how it works, but questions and comments are allowed.

Thanks for watching.

14 Comments

Now that is a fancy setup!

Even doing single profiles on parts, I'm always swapping bits because I never fully plan it out (getting better though!)

I like the safety feature of only one-motor-active lockout!

Even doing single profiles on parts, I'm always swapping bits because I never fully plan it out (getting better though!)

I like the safety feature of only one-motor-active lockout!

That’s an awesome idea! I’ve not seen something like that before but it makes a ton of sense from a production stand point. Love the intelligently built in safety.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

yeah thats a cool setup dutch. ive seen shapers with 3 heads but not a router table setup.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Very cool and innovative!

Mike

Nice; I’ve thinking about making a router table extension in the table saw wing.

This gives me more to consider.

This gives me more to consider.

Wow! very innovative!

I have a 1/8" round over in one router i keep for example. Chamfer is another I'd use all the time. There is a block plane chamfer jig that might be a good answer for me too. You are causing me to think about my uses. What lift are you using? Can you adjust the lift from above? I should check out small router lifts.

Thanks for posting.

I have a 1/8" round over in one router i keep for example. Chamfer is another I'd use all the time. There is a block plane chamfer jig that might be a good answer for me too. You are causing me to think about my uses. What lift are you using? Can you adjust the lift from above? I should check out small router lifts.

Thanks for posting.

Petey

i bet that cuts down on wheel making time by 85 % GR8 JOB 😍😎👍

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

That is a wonderful extension table, and you put in some great safety features on the set of routers. Well done and a good write up.

Main Street to the Mountains

Great design and engineering... and thanks for the thorough write up.

"5 Cheap routers"???? Thought Dutchland is too proud to stock 5 Bos¢h routers.

I know another woodie that had 4 routers mounted in a mobile table, but nowhere as sophisticated... will have to send him a link.

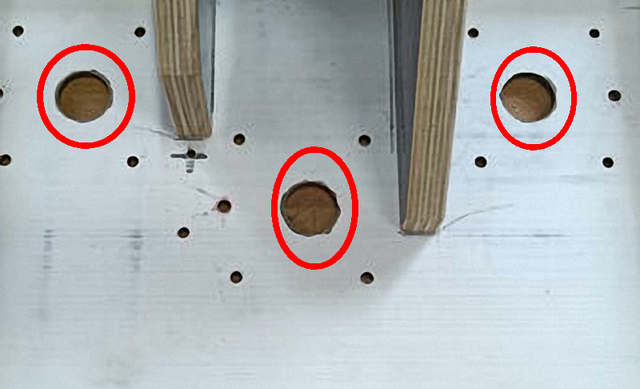

Were these cut,

with one of your yellow TCT "chippers" (😉😉😉)?

If your first cut is too short... Take the second cut from the longer end... LBD

Impressive setup Jan!

It would be awesome to have a three router setup like that. If I could figure out a way to raise and lower them quickly and accurately to a perfect predetermined height, without spending a million dollars, I’d leave one with a small round over and another with a chamfer bit. Think of how fast that would make edge work! And you’d still have one more for all the other bits!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Thanks all for you questions and comments.

Petey

What lift are you using?

LIttleBlackDuc

Were these cut,

Drilled with:

RyanGi

If I could figure out a way to raise and lower them quickly and accurately to a perfect predetermined height

For good understanding I do not raise or lower the routerbits. The height is only set once after a profile change, and the cutters never sink under the table.

Great design, interesting, meets the need well. Like it.

Ron

This makes a lot of sense for the type of work you do, definitely one for future reference.