RyanGi

in over 3 years

Shop Lighting

I’ll start: my shop is my converted 2 car garage. I used to have a window above the bench, but I walled it in to form a French cleat rack for hand tool storage. That was the right move, but it did remove the natural light…which sucks.

I have 4’ LED tube lights spread out to cover most of the shop, in general. Then I put additional lights over specific work areas on a separate circuit. One over the main work bench, one over the assembly bench, one over the welding table, and one over the metal lathe. I also have individual work lights on

I wish I had solar tubes throughout the shop. My space is another 425q ft. So I figure 6 of them would light the hell out of the place. I would still keep the daylight color LEDs of course, but I think as much natural light as possible is really beneficial to my work. I love the idea of a shop full of windows, but would never want to give up the wall space. Maybe 14’ ceilings!!!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

88 Replies

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

This is a 2017 picture, lots more stuff in it now. I have 6 4' LEDs and 8 windows plus one in the door. Still have plenty of wall space but there is too much clutter in the way to get much more shelving up without having to reach over stuff.

My office in in the corner behind me.

"Duck and Bob would be out doin some farming with funny hats on." chrisstef

anyway as for shop lighting i just did a quick inventory and came up with a grand total between both garages 62 4' LED tubes. now there not all on at once,usually ! i started switching them out as the old tubes or ballasts died then at about the half way point i just changed them all over. havn't had to change a tube in over 3 years now,and much brighter. i actually got rid of about 8 tubes. every light bulb or tube in my house id all LED !

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

The first thing I did was to paint the underside of the floorboards white to reflect light.

Originally I had secondhand 4’ twin flouros but they are all gone now. I have a mixture of LED light panels, battens and downlights all as plugins on surface sockets. I’ve recently added extra LED lights as with age the eyes need the extra lighting.

Life’s Good, Enjoy Each New Day’s Blessings

I also have a Milwaukee LED work light I use on the bench when I need side-lighting for carving or to inspect a finish. I “enhanced” its base with a cleat so I can move it anywhere in the shop easily. It’s probably brighter than I need in full-power mode, but it’s got three brightnesses, and I do sometimes use it full-on.

May you have the day you deserve!

We have a number of the "solar tubes" throughout the house. Totally eliminates the need to switch on a light during the day in the rooms without windows.

They are pricey, but I added a 10" for spot lighting over the table saw since there is limit places I could have the fluorescent fixtures installed. Still would like some more task lighting.

Half of what we read or hear about finishing is right. We just don’t know which half! — Bob Flexner

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

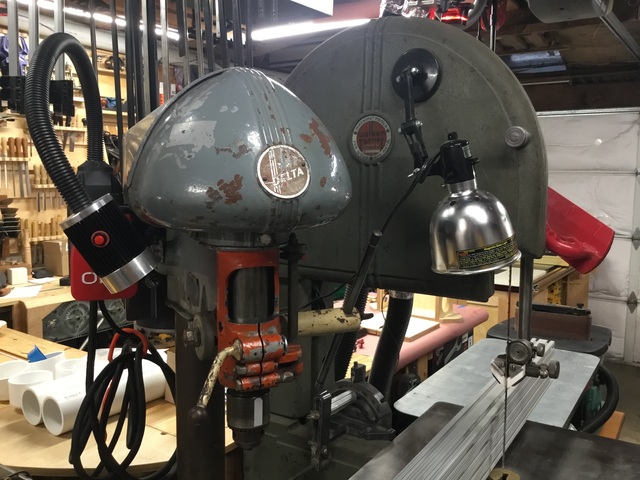

I’ve become very fond of the nicer magnetic base goose neck LED tool lights. I think I’ve got about 4 or five of them on different tools now. As my eyes get worse, I get more lights!

I’m just using some from Amazon, but has anyone used the ones from WoodTurnersWonders? They look great!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

The top 3’ around most of it is transom windows.

The front has double doors with a single door on the back wall which aligns with one of the front doors.

On a clear day, it’s plenty of light for milling, ripping and cross cutting.

There are 6 double-tube 8’ LEDs (5500’s) on 4 individual switches: one switch for each set closest to the wall and one switch for the next pair. This allows me to light any specific area of the shop or all of it as needed.

They were originally 12T fluorescent lights but I converted them to LED using tubes from Greenlightdepot.com

I procrastinated on the conversion but it was really easy. The hardest part was moving the ladder around.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Main Street to the Mountains

Am I the only one that thought that SG had a giant castor hanging from his ceiling next to his solar tube?

I carved a fake castor from wood and hung it up to trick the wife. She saw it, said "huh", then walked out. The 2 seconds of muted surprise was worth my months of work 😄

That'd be my air hose reel above the TS, great for blowing sawdust into the nether regions of my shop and directing the spiders out the door.

I started with 2 single bulb fixtures in my 22x22 garage converted to a shop. We don't have enough amps in the old sparkle box in the basement to go to crazy so I went with a chainable 3 ft LED lights off Amazon. There are 12 or 13 in total in the shop....I forget how many. And even with all those lights I still have a couple dark spots. My hand tool bench and table saw are lit REALLY well but my general purpose bench along the back wall not so much.

It shouldn't be too much longer with this setup though. We are getting a new sparkle box with 200 amp service when the solar gets installed. Then its let the old bank account recover a bit and get a subpanel in the shop. I will probably pull all my only lightning hoses and then have a professional sparky come hook up the sparkle boxes.

Long story short, having 125A in the shop is a godsend!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Main Street to the Mountains

I did the same in my garage with 4' fixtures and there is some RF but not as bad. I could still use a radio in there....if I wanted. I converted the fluorescent lights in two bathrooms the same way.

There are some very nice looking flat LED panels that would work in some shops with limited ceiling height. They are only about 1" thick. I put an 18" square one in the kitchen of my rental house and it looks and performs much better than the fluorescent fixture which seemed to need frequent tube replacement. I heard that frequent switching on and off of fluorescent lights is what burns them out so LEDs solve that problem.

I've often thought that if we could capture and store lightning the energy worries are long gone. Like a massive capacitor that you could step down and slowly release.

If you want to start a conversation that will never be resolved, ask if lightning is A/C or D/C current.

Then I realized it's shop lighting, not lightning. I just get LED strips when they're on sale. I probably have 12 - 15. When they start flashing, I beat the sh*t out of them and toss them in the trash.

There's roosters laying chickens,and chickens laying eggs... John Prine

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".