hairy

in over 3 years

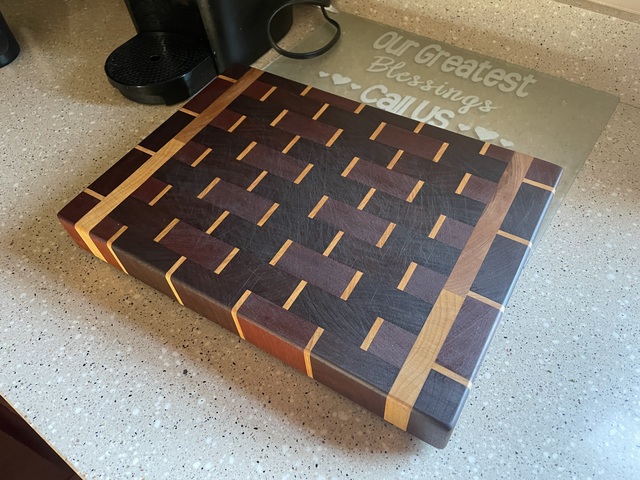

let's talk about cutting boards

I'm gearing up to make a thick endgrain board. I want to cut an 8" bowl into 1 side, so I'm thinking 3" thick, with a 1 & 1/2" deep bowl. I'm worried the bowl might weaken it , that's why 3" thick. Would 2" thick with a 1" bowl be better?

Here's my stock. Hard maple and walnut. Maple is 2" thick, walnut 1 and 1/4". Longest board is 62" and it has defects to work around.

I want a big board, 18" x 18" x 3" would be great if possible. I don't want to plane the maple down to the thickness of the walnut.

My plan is to cut the maple into strips the same size all around. Glue it up, cut it up and make a square end grain board.

Then cut the walnut into strips to make end grain strips the same thickness as the maple square.

These will be glued onto the perimeter of the walnut. This will be long grain to long grain.

When I get a maple square with walnut perimeter board I'll mount it on the lathe to cut the bowl. At least I have that all worked out.

I'm worried about the perimeter. I think this will work because it's a long grain walnut to long grain maple.

2 opposite sides will be longer and the other 2 will fit into these on the ends. That will be 1 glueup for all 4 sides onto the maple.

Is this making sense? I admit there's a lot I have to learn about cutting boards.

Would edge grain be better? I can't figure how to glue a perimeter onto an edge grain board, 2 ends will be long grain to end grain. I don't think that will work. Without the perimeter, the edge grain would be the easy way, with all long grain to long grain joints.

I have time on my side, this is for next Christmas.

I'd like to hear your thoughts on cutting board construction. I'd like this to be 1 stop shopping for cutting board help.

There's roosters laying chickens,and chickens laying eggs... John Prine

18 Replies

I don’t know why I haven’t made a cutting board. Something about seeing so many of them made and already having three in the kitchen. Although one of them is cracking our and I’ve already repaired it twice so maybe I do need to make one….?

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

There's roosters laying chickens,and chickens laying eggs... John Prine

You have your work cut out for this one, and it's going to be heavy. The bowl sounds interesting.

What about using miters on the corners for that perimeter, you will get the long grain to long grain (if I am understanding correctly). Then for the bowl part, would it not be better to use a router and have a flat bottom. I have always had a difficult time turning end grain. As for the thickness, if you don't go past the center point it should be fine. That's my thoughts.

Main Street to the Mountains

The bottom needs to be round.

There's roosters laying chickens,and chickens laying eggs... John Prine

Main Street to the Mountains

There's roosters laying chickens,and chickens laying eggs... John Prine

Main Street to the Mountains

What I’d actually do is cut concentric rings out with z-axis steps using the Shaper Origin, then use gouges to smooth it all together…but I know that requires a specific tool…so forstner bits work for the bulk of it!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

It was just a plain straight grain 19mm x 52mm pine... Its only accoutrement was a box to house it under when not in use,

and a pull hole to fish it out. I recently started to prop it up on bench cookies,

no more slipsies and since then I've never had to engage its reverse gear to park it under the box,

It might be time to either wash it, flip it or give it a back rub with my drum sander.

If your first cut is too short... Take the second cut from the longer end... LBD

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

I've only made a handful of cutting boards so I can't offer a lot of experience-based advice. I will say that the nice thing about making endgrain boards is that you always have long grain glue joints.

These will be glued onto the perimeter of the walnut. This will be long grain to long grain.

Could you add a sketch.

I don't think it would make any difference if the thickness was 3" with a 2" bowl or 2" with a 1" bowl.

Could you add a sketch.

I'm going to be lucky to get 1 & 1/2" thickness. Defects in the wood and mistakes on my part is making this smaller.

I just got done with the 2nd glue up, with the end grain top and bottom. It's about 15" square x 1 & 1/2" thick. All maple.

I hope to make endgrain strips of walnut to go around the outside.

There's roosters laying chickens,and chickens laying eggs... John Prine

I have to cut it down more. This one is circling the drain.

There's roosters laying chickens,and chickens laying eggs... John Prine

Main Street to the Mountains