SplinterGroup

in over 3 years

More from SplinterGroup

Laser basket weave from veneer #1: Intro Blabbering

This is

part 1

in a

3 part

series:

Laser basket weave from veneer

-

Intro Blabbering

-

Making the cuts

- Intro Blabbering

- Making the cuts

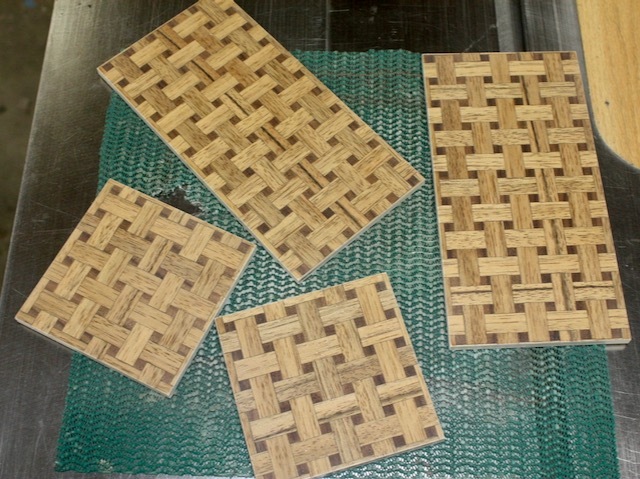

I did this pattern before as one of my first stabs at cutting veneer with my laser. This time I was going to better document the process and instead of an experiment, I actually had a plan! (sort of).

I've always liked this pattern, From a technical perspective, best thing is all cuts are straight and square. Worst thing is all cuts must be straight and square 🤔

A little off on either, and gaps will form and propagate throughout the design.

Before I tried laser cutting, I'd use a cheap veneer saw and Exacto knife for straight and clean edges. I did ok, but the knife tends to follow the grain and my saw sucked. Plenty of age old techniques and skill required for even this simple-seeming task, something that people like Paul {shipwright) have long ago mastered but not me.

In comes the laser. Burn the buggers out!

Where a good knife will leave a clean edge and with a slight taper, a perfect gap-free fit, the laser will leave a gap due to the beam kerf and a charred edge.

Several things can be done to minimize those "features"

The Laser

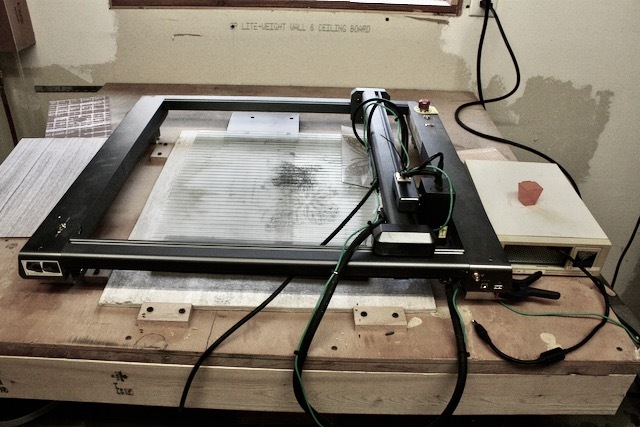

I have a 10 Watt optical power diode laser (my first). Typical hobby grade unit. To use one, good software that goes far beyond anything delivered with the device is required. At this time, LightBurn is at the top of the heap. Really lets you get the most out of the tool for a cheap price.

My setup is a swing down table in my spray booth. Ventilation and compressed air are already there so a perfect place to work.

This is the Ortur Laser Master 3 (LM3), a typical gantry style with a 400mm x 400mm workspace.

One can go nuts with setup. Since I also use this space for finishing, the table gets folded down and the laser set aside. I placed 3/8" steel pins to replace the feet in the corners of the frame. Matching holes in the table top allow it to be securely located in the exact same location when setting up. A backer (spoil) board from a scrap section of Hardie siding (cement based) keeps the laser beam from cutting a hole back to China in the table top. I burned a layout grid on it's top so I know where to place things to cut/etch, even if it's been months between uses. You can see the wood blocks used to align this spoil board to the table.

On top of that, to hold the stuff being cut I use a piece of fluted glass I had. The peaks hold the veneer while the flutes let the smoke escape from below.

There are lots of other ways to get a working setup, this is what I had handy.

Air Assist

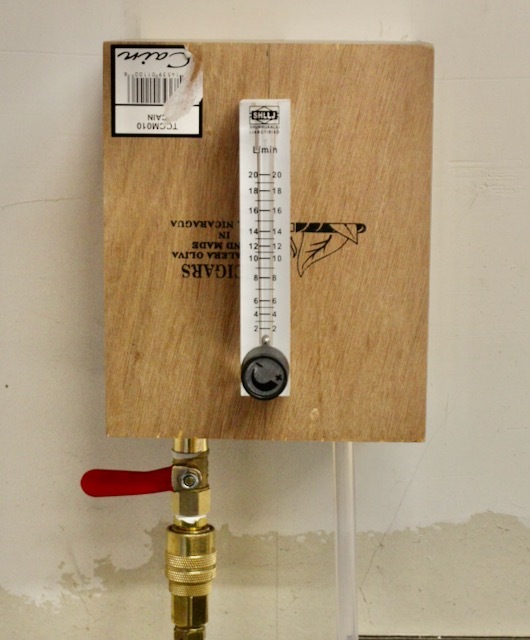

The laser head has internal fans to keep it cool, but when lasing most materials soot and smoke will be created. There also is an advantage to blowing air into the cut to clear away burned crud.

Most of the lasers will route this airflow through a "funnel" that also surrounds the laser lens, this airflow will help keep the smoke and soot off of the lens. If anything builds up on the lens, the beam will begin cutting your lens and quickly trash it.

Not much air is needed, even a good aquarium pump will do. I found a cheap airflow regulator so I can record exactly what I use for each material. The key is airflow, not air pressure since if you change a hose the pressure will also change, but if you just keep the airflow constant, you'll get the same results at the laser.

Mounted in an old cigar box with a slip in lid that makes for easy removal if I need to. Measurement is in Liters/minute (Litres/minute for y'all across the ponds 😬)

Anyhoo, onto the project in part 2

26 Comments

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Ron

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Gotta admit I immediately thought laser engraved as opposed to the heroic cutting of veneers... though engraving could leave little stock "under" the engraving.

I've never tried cutting veneer per se on the laser as I was always intimidated on the air blowing small pieces away.

just my 2 bobs worth...

I've always laminated veneers onto 3mm (or dressed down further) MDF

and have some

When I cut inlays, I cut upside down on the assumption that the kerf is a fraction wider at the top and narrower at the bottom where the laser strength is diminished.

During assembly the minor bevels will assist in jamming the pieces together.

This is probably irrelevant in your scenario, however, it is a method that has worked for me.

If your first cut is too short... Take the second cut from the longer end... LBD

Your idea of cutting after laminating is ideal with your mega watt device, if I tried that things probably would catch on fire after 10 passes.

BTW, to all laser owners... if you are concerned about fire, ditch your powder extinguishers and go for CO2. Powder will do more damage to the laser that he fire.

If your first cut is too short... Take the second cut from the longer end... LBD

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

CO2 has a smothering effect as well, as it displaces air but is somewhat short lived. It also removes heat which attempts to brings the temp below ignition temp which will also stop the fire. The nice part about CO2 is that you can direct it right where it’s needed, but it does mean you’ve got to be a little more up close and personal (as opposed to dealing a blanket over something and moving away). There’s no clean up at all, but if a large amount is used in a confined space it could be an issue for someone trying to breathe.

‘Regular’ extinguishers, sometimes called Dry Chemical extinguishers, are mostly Bicarbonate powder based, with some other stuff. The powder is super fine and spreads very easily. It kinda covers/sticks/melts to burning items and smothers them. They leave a LOT of residue and are a pain to clean up, but they work well and are cheap.

There are about a dozen more types, but that’s enough for lasers!

There. Now you know more than what you ever wanted to about fire extinguishers…

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Seems like it shouldn't affect the cut since it is the heat that does the work.

As to fire extinguishers, I have a couple of halon units pulled from aircraft. I wonder what residual effect they might have on electronics?

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

My concern is that out room with the halon has all sorts of stuff that shuts down (ventilation) and drop down door covers before the discharge. Me thinks it wants to take over the atmosphere in the room and if my laser has it's ventilation running, the halon may just get sucked out and just piss of AlGore.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

I was advised against my on hand powder job sitting next to my laser and recommended a CO2 by my laser service guy. Just passing on... "horse/water/drink" thingy.

If your first cut is too short... Take the second cut from the longer end... LBD

Think of it as the exact opposite of helium. Goes away just as fast!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".