RyanGi

in over 3 years

More from RyanGi

Knife makers vise

I do a bit of metal working, but it’s more on the furniture or fabrication end, with welders and mills and lathes and those fun things, and less forging and hardening. So there was a learning curve not only to how to put these pieces together, but also the tools and work holding associated with it. As an aside, that’s actually my favorite part of swaps: learning new skills and new tools!

I cheated and bought myself a 2x72” grinder (which I’d been eyeing from a distance anyway) which makes quick work of roughing in shapes, but I needed something to hold the blades while I hand worked the handles down to their final finished state. I saw a couple different DIY blade vise options out there on the interns, so I figured I’d knock one up.

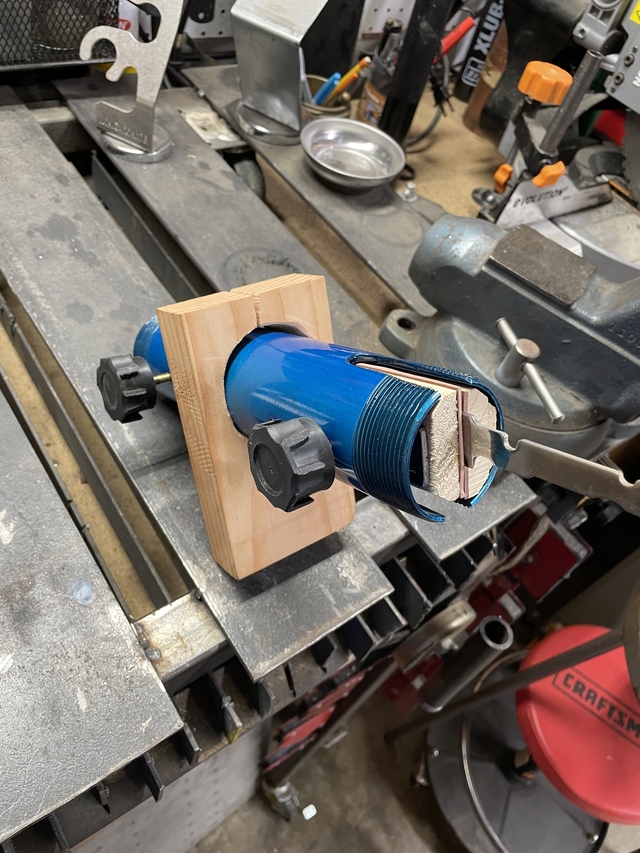

This is just 2” gal pipe that I milled slots in, drilled and tapped for tensioning screws, and built internal jaws patterned after the pipe ID.

To give me easy 3-axis adjustment, the pipe slips into a wooden block with a thin relief slot on top. When placed in the vise and tightened, it locks both the tilt and axial rotation of the vise in place. By spinning the vise I can change the pan potions. When I tear up the block with the bench vise it’s a super simple replacement.

I media blasted and powder coated it a pretty blue…mostly ‘cause that’s what was in the hopper already. At some point I’ll post my media blaster/powder coating set up. It’s a small shop version that’s actually pretty compact and on wheels. Works great!!

Anyway, it worked out just perfect for the knives I worked on for the swap. Always love getting new tools, and making them is even better!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

15 Comments

Angellos

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Angellos

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Nice stuff there Ryan

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

I'm all about simple, so seeing the words "dumb it down", it moves up the pile of previous vices I have seen elsewhere. Win Win Win. :-) As usual nice job Ryan.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Thanks for posting this.

Petey

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

I have a carving attachment that holds a chuck for my wood lathe. I've held odd ball stuff with it by removing two jaws and a home-made a-dapter kit

There's roosters laying chickens,and chickens laying eggs... John Prine

Regards Rob

Way better than a pair of vise grips and the ability to move it any which way is the real utility.

Reminds me of a fly tying vise on steroids.