RobsCastle

in over 10 years

CNNP Sheoak Drink Coasters

The cross section caught my eye as a interesting Drink Coaster

so I brought it back home and with my bandsaw I cut it into useable billets.

then cut one of the most interesting sections into about 16mm thickness slices

my next intention was to produce an even thickness slabs to make drink coasters.

I made a thicknessing base and screwed a piece on and fed it into my thicknesser

I fed it in and slowly lowered the blades to try and thickness them.

All went well for a few passes then it disintegrated on me.

so I tried again this time using hot melt glue to retain the piece, again all went well for a few passes and I though I was getting somewhere.

However again it disintegrated.

I decided to give up on the process as t was not working well.

So I stopped to reassess the whole process.

a couple of questions to the brains trust if I may.

1. How would you do it.

2. In your opinion do you think its a achievable or am I wasting my time.

3. Or just completely crazy, and i should just turn the tools off and walk away.

Oh and almost forgot is it actually sheoak or something different.

Regards Rob

14 Comments

Thanks for the reply and suggestion, it makes you wonder as you get older just how much you seem to stop thinking.

I actually doubted my idea would work in the first place but failed to consider other options,.

I have all the tools you mention however didnt think to consider them so thanks.

I will power p the disc sander tomorrow and continue on.

Thanks again

Regards Rob

1. How would you do it.

I would just simply let you do it and grant you the luxury of all the hassles and failures...

2. In your opinion do you think its a achievable or am I wasting my time.

That's 2 questions, but the long answer is...

- No

- Yes

3. Or just completely crazy, and i should just turn the tools off and walk away.

I'm no engineer... the closest I got was to catch these red rattlers in Victoria during the 70's,

However, (back to your stump) at the early passes there was enough "meat" to support the sides, but as it gets thinner, it will shred like pulled pork (preferably cooked... saves the blood).

May I suggest you abandon your quest for that wallet and buy a new one... then use that to amass your shekels to buy a replacement sander, as Amelia will never flash yours again.

Looking at the gnarled wood, I would suggest stabilising... flood it with CA or soak it in Earl's before maybe 1/2 thicknesser passes and then go sanding. Maybe seal the surface and you could use some vac clamps to hold the odd shapes for sanding... ROTEX... don't get blindsided by pottzy's Bos¢h.

Failing that, start drinking out of casks... they don't need bloody coasters.

Fire up Treasures of Nadia... it'll give you inspiration, or at least take your mind off your troubles.

If your first cut is too short... Take the second cut from the longer end... LBD

A sander could work.

A good sharp low angle block plane should work. Always work from the outside towards the center.

I’ve made a few by putting a stop on the bandsaw so the thickness is even, and just leaving them “rustic”.

-- There is nothing like the sound of a well tuned hand plane. - https://timetestedtools.net

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

If your first cut is too short... Take the second cut from the longer end... LBD

Flatten one side, flip them over and finish to thickness then sand the tool marks out. That way you get uniform thicknesses and perfect flatness. If it was just one or two, I'd use a belt sander but for that many, this will be faster and give more consistent results.

Cheers, Jim ........................ Variety is the spice of life...............Learn something new every day

If your first cut is too short... Take the second cut from the longer end... LBD

If your first cut is too short... Take the second cut from the longer end... LBD

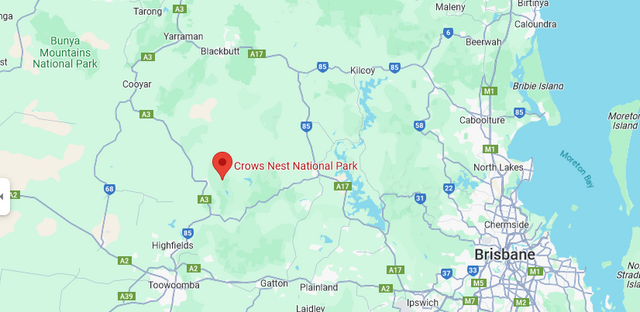

Its about 6km east of Crows Nest, 50km north of Toowoomba.

Regards Rob

This method is used by me for all my small stuff.