Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

LIttleBlackDuck

5542 posts

and

56 followers

in over 3 years

in over 3 years

More from LIttleBlackDuck

Hints and tips that some may not have heard of. #52: Dis_CORD in the workshop.

Hints and tips that some may not have heard of. #51: Glass Jars for those recalcitrant chems.

Hints and tips that some may not have heard of. #50: Crank Up your Tracks.

Hints and tips that some may not have heard of. #49: Defrosting Your Ice Maker.

Flowerdale – "Deliverance" on the Road.

A collection of Clamps. #13: Small Parts Air Clamp.

This is

part 13

in a

29 part

series:

A collection of Clamps.

Boy and Girls,

Having achieved my small parts vacuum holding agenda with my Air Cups and Rockler Air Pods, unlike Tim The Toolman, I wanted to go smaller.

I am now delving into blog/project material as this being shop made, a review is inapplicable.

I am now delving into blog/project material as this being shop made, a review is inapplicable.

When I bought my Grabo (yet to be presented as a clamp) off Izzy Swann, it was bundled with a base plate that can be combined to use as a vacuum pump. Before my foray into Air Cups, which was instigated by me purchasing a pair of Izzy Swann’s template connectors, for use with the Grabo and his vacuum base, which turned out to be a fizzer for me because of the groove in it,

and an uneven surface profile,

with only a 4mm dia. seal.

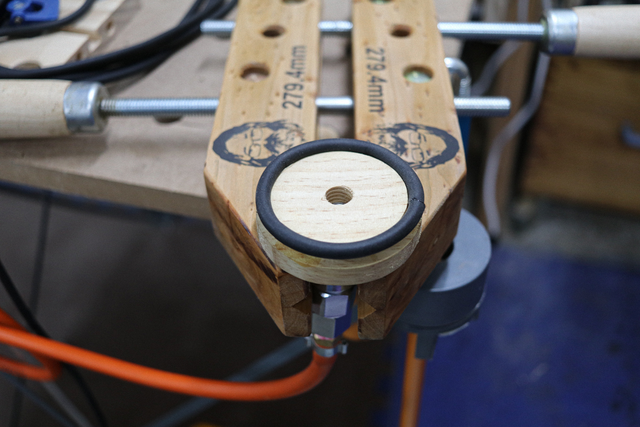

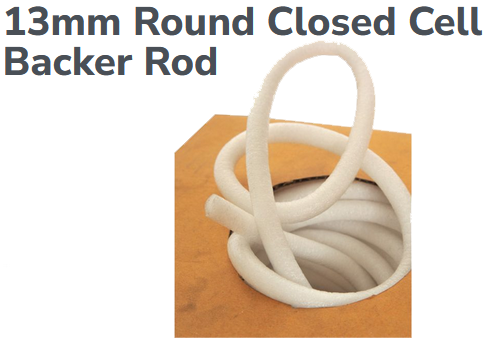

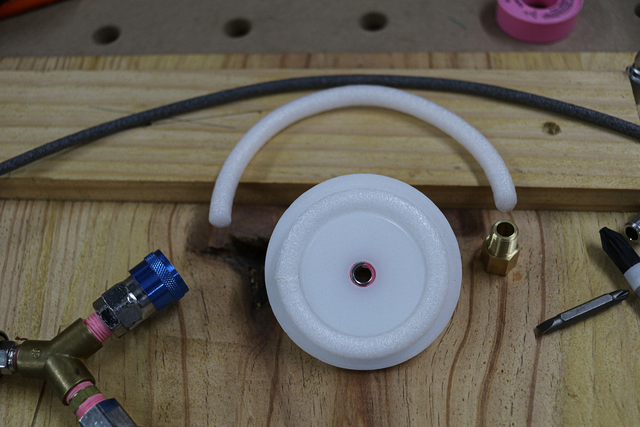

On somebody’s recommendation, I got onto this 13mm Round Closed Cell Backer Rod

which I customised (CA glued the ends into a ring) to fit into the groove,

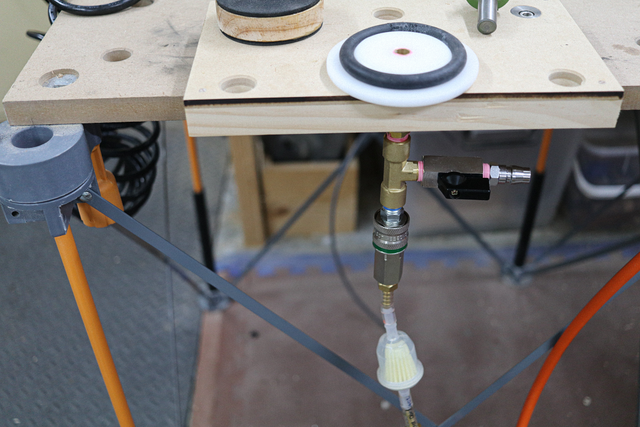

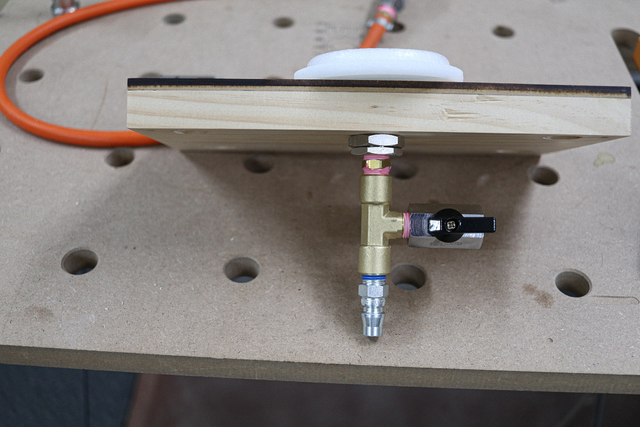

rigged it up with some air hardware,

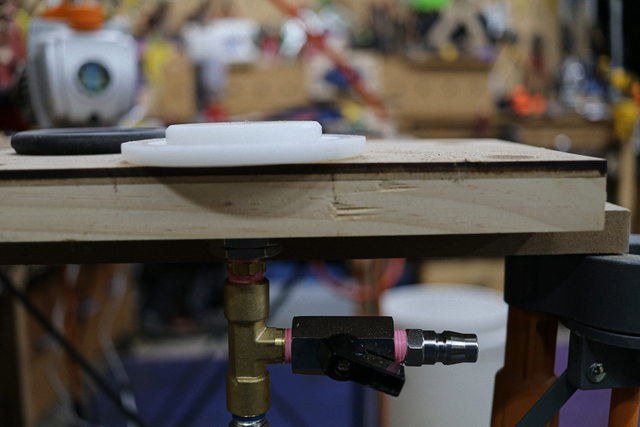

to solidly mount into an MFT style mountable base. It had an escape valve to release the vacuum for easy separation.

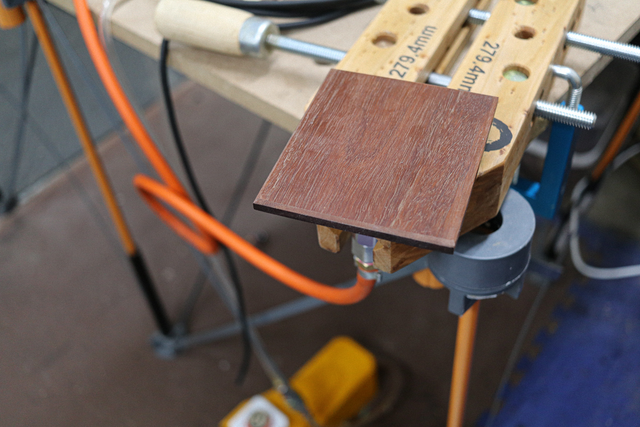

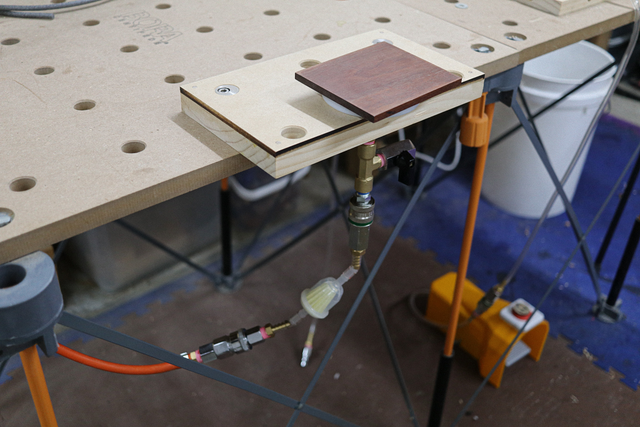

Connected it up to one of my vacuum pumps (BacoEng/Grabo), and slapped a small piece of timber on it,

Held like a charm… tried to pull it off, and after exerting enough force to confirm it held well, I eased up… I was gruntled. While the 13mm may have been a tad too thick, it was soft enough to compress down for a good hold.

Unfortunately, I put some lateral pressure on it and the piece of wood slid around on that 13mm Round Closed Cell Backer Rod… this time I was disgruntled.

Unfortunately, I put some lateral pressure on it and the piece of wood slid around on that 13mm Round Closed Cell Backer Rod… this time I was disgruntled.

Thought about some type of rubberised seal and not having a local supplier, after some surfing bought some 6mm and 9mm Foam Rubber Seal Weather Strip (not sure of exact size needed other than not 13mm)… the 6mm strip (3m long),

Made up a ring out of the 9mm rod to fit the template connector,

loaded that piece of timber and again I was gruntled.

Now even I realised that not everyone was going to buy Izzy’s template connector when they don’t own any of his templates, so it was back to shop fabrication.

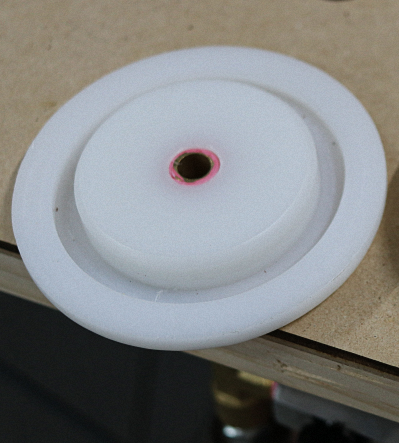

I had some shop made bench cookies left over from my mini workbench,

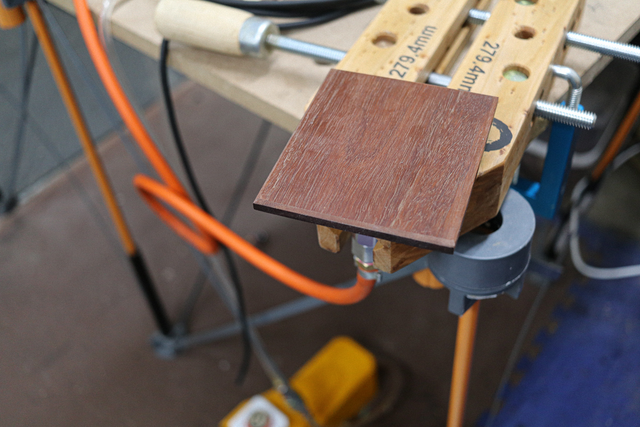

and even some without the rubber pads glued on. Tapped it with a ¼ thread and screwed a Nitto air fitting into it,

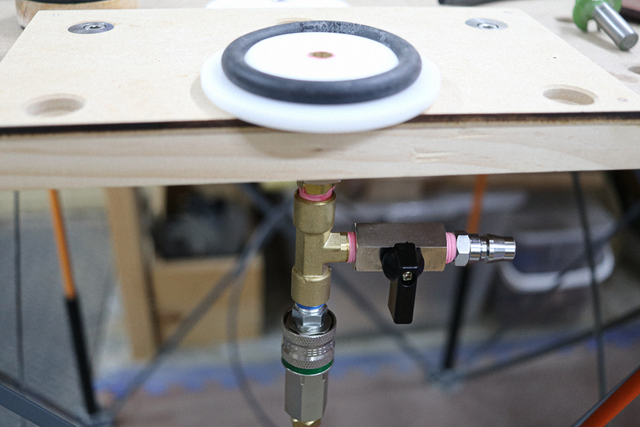

For the seal, I used this router bit

(maybe a tad oversized), to route a grove,

to house another glued up seal,

and placed the bit of timber on it…

more gruntling ensued. Then it was time to test for size (or lack thereof)… mounted a 67mm dia. cookie blank,

Went searching for smaller diameters and found this spray can (top) at 64mm,

Further search resulted in a failure with this 63mm top,

which did not go over the thick perimeter of the seal.

To me 64mm was small enough, at least for the moment, and if future requirements dictate, I could go for a smaller dia. “cookie”, however for that I will not drill all the way through the cookie and drill a connecting hole from the side. That way I could glue the cookie to the mounting base without having to configure mounting hardware.

I think my journey with air clamping has ended as I DO NOT intend to make an air clamp for my lathe just to turn bloody bowls.

------------------------------------- ooooOOOOO00000OOOOOooooo -----------------------------------------

Don’t be crafty Craftisians,... SHARE your craft!

If your first cut is too short... Take the second cut from the longer end... LBD

5 Comments

Very cool....lots of good info to digest. I do have an unused set of Rockler pods but I have an oil pump which I have no intention of using. So on hold until I get a oiless.....

Mike

Nice write up ducky.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Regards Rob

Time for a dip in the cee-ment pond!

If your first cut is too short... Take the second cut from the longer end... LBD

Jethro can do some cyphering for us, so'uns we can figure out how to get them sticky clamps to work.

Max is the only one left alive from that bunch.

Max is the only one left alive from that bunch.

More from LIttleBlackDuck

Hints and tips that some may not have heard of. #52: Dis_CORD in the workshop.

Hints and tips that some may not have heard of. #51: Glass Jars for those recalcitrant chems.

Hints and tips that some may not have heard of. #50: Crank Up your Tracks.

Hints and tips that some may not have heard of. #49: Defrosting Your Ice Maker.

Flowerdale – "Deliverance" on the Road.