SplinterGroup

in over 3 years

More from SplinterGroup

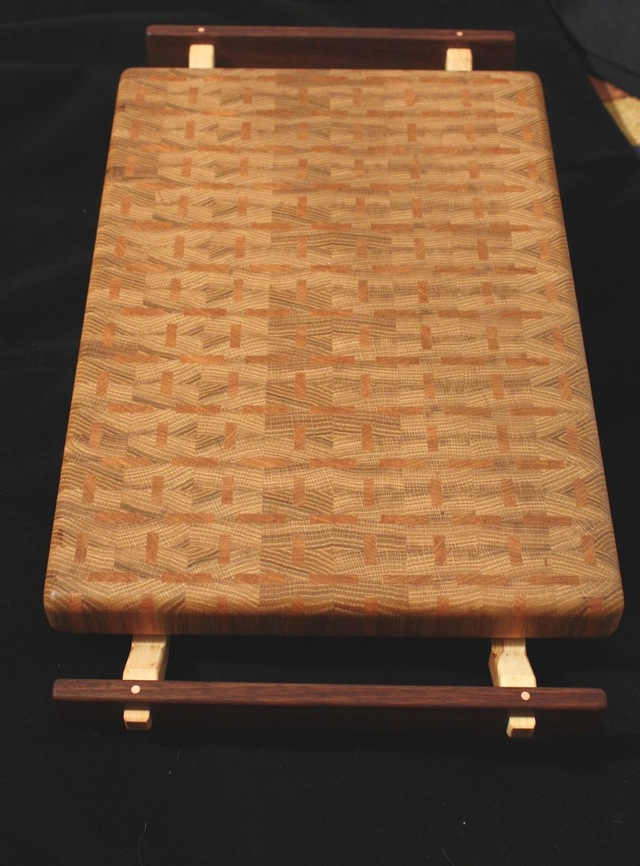

Indestructible Cutting Board

Well, maybe non-self destructing!

The board is end grain Hickory, about 20"x12"x1.25" thick

I was bored so a quick cutting board project seemed appropriate, but I wanted to experiment with construction methods and get something different.

Searching the #%^!X archives I found well over 100 pages of various style cutting boards, from the simplest to the most complex. I've always been paranoid about joint failure in the boards I have made (I've experienced a few), so I decided to make a board that would survive. Years ago I bought a commercial board, a "Boos" brand. This thing is built like a tank, face grain rock Maple. The wood is basically impermeable to moisture, the long-grain glue joints all expand/contract in unison. Basically the 'perfect' board, yet boring and bland as it gets.

I've made fancier boards, but I never advertise them as anything more than a bread board or serving board. This implies they are not suited for wet areas and when they do fail (they all will eventually) they hopefully have served their purpose for years.

What makes a board survive? For this board I decided to consider what usually destroys a board and try to build around it.

In my opinion and in no particular order….

Long grain glue joints only

Glue doesn't grab as well to end grain so I made sure only long fibers of the wood are glued. I also wanted lots of glue surface and mechanical connections. Splines were the answer to this. I also went so far as to keep face and side grain glue joints segregated since radial and tangental expansion rates differ. This board is glued with TB3. I switched to epoxy from TB3 a few years ago since the TB3 makes a colored glue line and the epoxy gives me much longer working time to get everything aligned and into the clamps. The problem was that I would get some joint failures along the epoxy seams. I'd like a nice clear glue with some give, water proof, and a long working time. I haven't found it yet…

No mixed species

This was a tougher decision. So many of the boards displayed on #%^!X use various woods to achieve incredible effects. If the two woods sharing a glue joint don't react to moisture equally, the glue joints will experience a lot of shearing forces and eventually fail. Look at wood expansion tables some time and you will see that a typical sized board can grow/shrink a good part of an inch. If both woods don't do the same, something has got to give. I could have chosen the standard rock Maple, but that is just too boring. I went with Hickory instead (the handles are Walnut). I get some interesting grain and still some protection from easy water infiltration. Having an end-grain board gets me even a bit more interesting wood figure out of the Hickory.

Keep the water away

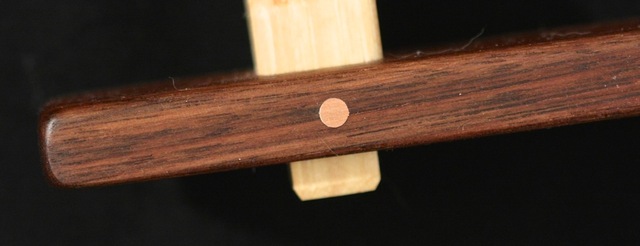

Having a piece of wood sitting with one side in a puddle of water on a countertop is just asking for something to warp. This board uses 'feet' to keep the bottom out of any countertop puddles. Finger grooves are nice board features, they make the board easier to pick up and hold. I decided to integrate the feet with handles to kill two birds as they say. Since the board will expand up to 1/2" (based on an on-line wood expansion calculator), I needed to make sure the feet/handles would not bind up when this happens. These slots allow the motion to go on behind the scenes (stainless steel screws of course). Non-slotted screws in the center of the legs are used to keep the handles centered. Square plugs fill the screw holes and make the raised feet. Mineral oil (soaked for a week) will help fill the pores and keep water out for a while.

Make it nice

One thing most boards on #%^!X have going for them in terms of survival is they are just too darn purdy to trash up as a cutting board. I'd bet most of the boards end up on display or as a serving board in the center of the dining table. Keep a board from the water and take care of it, it will last; ergo I added a few embellishments just for fun (but they also help keep the board in one piece!). I used copper pins to help secure the through tenons in the handles.

So nothing fancy created here, just something that should survive better in a harsh environment compared to other boards I have made.

Thanks for looking!

32 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

I wonder how it has held up after 7 years....

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Ron

No name noobie here

Main Street to the Mountains

Life’s Good, Enjoy Each New Day’s Blessings

-- Soli Deo gloria! ( To God alone be the Glory)

Great job!! Hickory is some hard stuff and heavy too.

daveg, SW Washington & AZ

The Other Steven

Generally I love hickory for the beauty, but I hate it enough that when ripping a beautifully flat/straight/square plank, I'll chop all the resulting twisty "pretzels" into tiny pieces 🙂

Ron, Steven.

Board was (and has) been made to sell. Already have about 6 CBs stuffed in the gap between the microwave and cabinet for personal use. I can see the attraction of having butcher block counters!

Due to my irrational fear of overly complicated cutting boards (apparently there are meds for that) I prefer your design’s “relative” simplicity over many other designs I’ve seen….and the side tray handles are the added bonus that really brings it all together.

Nicely done!

If I didn’t laugh at myself, I’d lose my mind.

As Elvis would say

"thankyouverymuch"

I would sure like to see some process photos on how you got the end grain in those positions. Or should I look on #%^!X. Hope I spelled that right. Lol

James McIntyre

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

No additional info over at #%^!X, moved it over here 8^)

I just cut long square strips and cut the spline grooves on all sides, glued them up side-by-side with a spline inserted between each strip.

The "board" was then cut at 1-3/8" intervals to make end grain strips. These were glued up side-by-side with short (1-3/8") splines between. Sanded to 1-1/4" on the DS.

The last glue up was where I wished for a very slow set, waterproof, clear glue 8^)

It’s like the evil character on Harry Potter who’s name can not be spoken.

James McIntyre

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.