Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

LIttleBlackDuck

5512 posts

and

56 followers

in over 3 years

in over 3 years

More from LIttleBlackDuck

Hints and tips that some may not have heard of. #52: Dis_CORD in the workshop.

Hints and tips that some may not have heard of. #51: Glass Jars for those recalcitrant chems.

Hints and tips that some may not have heard of. #50: Crank Up your Tracks.

Hints and tips that some may not have heard of. #49: Defrosting Your Ice Maker.

Flowerdale – "Deliverance" on the Road.

Mini Office Workbench #5: Drilling the easy dog holes

This is

part 5

in a

13 part

series:

Mini Office Workbench

...

-

Laying out the Index holes

-

Drilling the easy dog holes

-

Chamfering, and drilling awkward holes

...

...

- Laying out the Index holes

- Drilling the easy dog holes

- Chamfering, and drilling awkward holes

...

Boys and Girls,

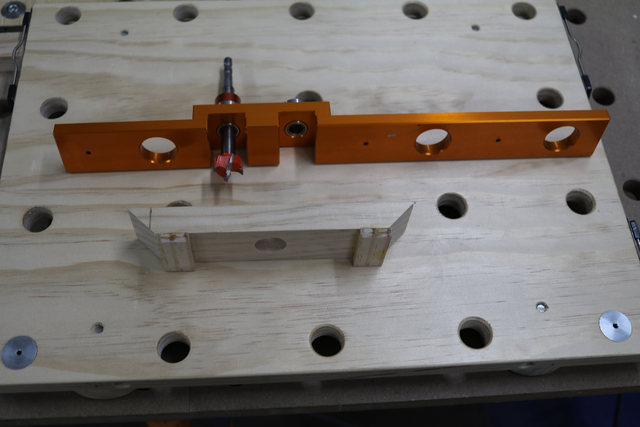

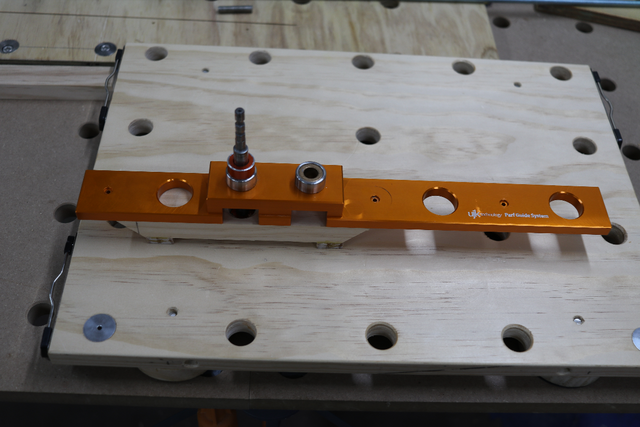

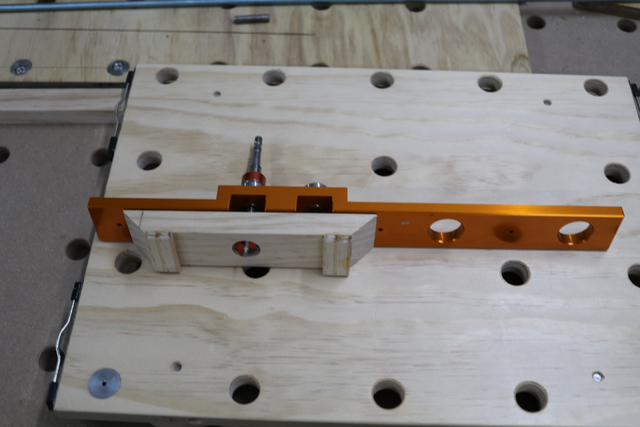

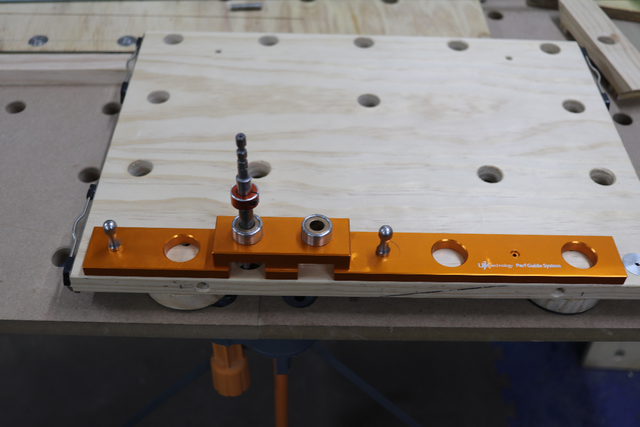

This blog is about drilling the 20mm dog holes using the UJK Parf jig. The jig operates on alignment with the pre drilled 3mm holes (Part 04).

I will attempt to avoid getting into a review of the jig, however, I need to explain some of it’s features for better understanding of what is required to drill the 20mm holes.

The jig has two positions for the TCT bit and I made a template for setting the depth stop collar to roughly 19.5mm for movement of the bit between the 2 jig’s guide collars

With the depth set, the jig can be positiones on the board using the TCT bit’s 3mm tip to line up the hole an 2 pins to align/secure the jig,

ready for drilling.

Clamp the jig (optional, but recommended), attach the drill, the chip catcher, the dusty…

If you want to know what happens next, you’ll have to watch the video,

This procedure is what I refer to as the “easy holes”, which should permit approximately 50% of the holes to be drilled depending on your drilling order.

The next blog will describe what is required for the remaining “difficult(er) holes”.

If your first cut is too short... Take the second cut from the longer end... LBD

3 Comments

Some fancy jiggery you have there!

Looks a bit fiddly, but unless one had a mill with a great X/Y range, t'would be aggravating to get anywhere near as accurate.

Just have to bring it up: You have a WP "box cutter" with a pencil blade? I can see how it can be very useful but only the minds at WP would tool up to make something like that 🙂

Looks a bit fiddly, but unless one had a mill with a great X/Y range, t'would be aggravating to get anywhere near as accurate.

Just have to bring it up: You have a WP "box cutter" with a pencil blade? I can see how it can be very useful but only the minds at WP would tool up to make something like that 🙂

Nice jig!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Haven't tried it as a throwing knife, but after the first 2 years I'm still on the same blade. Must be the advertised "carbon fiber reinforced graphite blade"

Bought 3 packs of 3 about 5 years ago and am still on the 1st blade from the 1st pack.

Bought 3 packs of 3 about 5 years ago and am still on the 1st blade from the 1st pack.

If your first cut is too short... Take the second cut from the longer end... LBD

More from LIttleBlackDuck

Hints and tips that some may not have heard of. #52: Dis_CORD in the workshop.

Hints and tips that some may not have heard of. #51: Glass Jars for those recalcitrant chems.

Hints and tips that some may not have heard of. #50: Crank Up your Tracks.

Hints and tips that some may not have heard of. #49: Defrosting Your Ice Maker.

Flowerdale – "Deliverance" on the Road.