Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Ron Stewart

936 posts

and

25 followers

in over 3 years

in over 3 years

Giraffe Bookcase #3: Dowel Joinery

This is

part 3

in a

9 part

series:

Giraffe Bookcase

-

Cutting the Case Parts

-

Dowel Joinery

-

Cutting the Legs

...

- Cutting the Case Parts

- Dowel Joinery

- Cutting the Legs

...

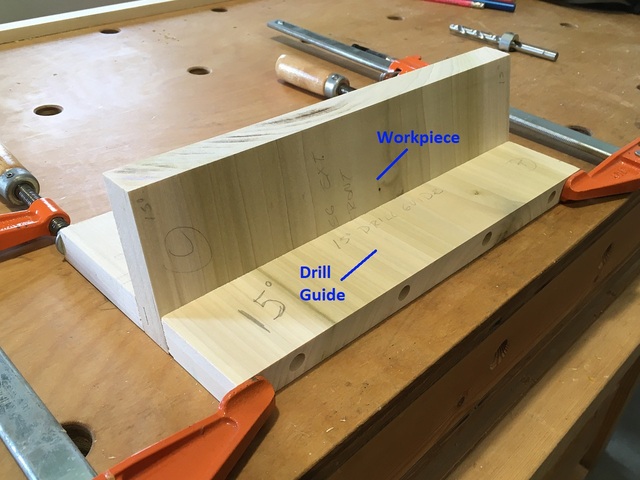

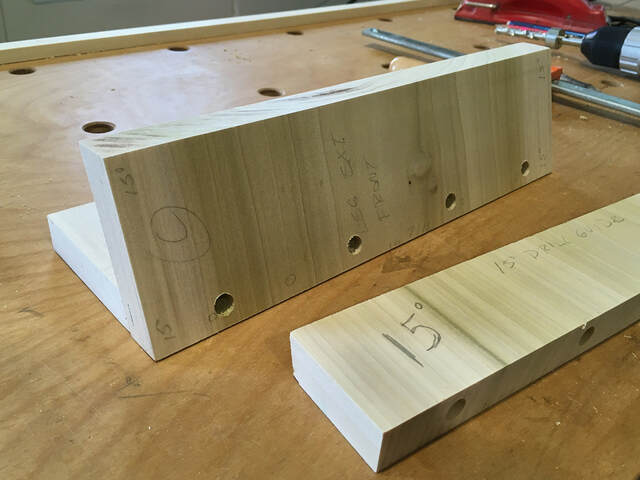

Before I could start drilling the dowel holes in the part faces, I had to make the angle-specific drill guide blocks I mentioned in a previous post. To do that, I used my doweling jig to drill holes all the way through the angle-specific cutoffs I had saved and squared off the opposite ends. While drilling the holes, I just had to remember to place the pointy end of the blocks against the jig's fence. (The JessEm jig doesn't necessarily center holes in the stock's width, so it's important to use a consistent reference edge.)

When drilling holes in part ends, I also had to make sure to place the pointy end of the part against the jig's fence.

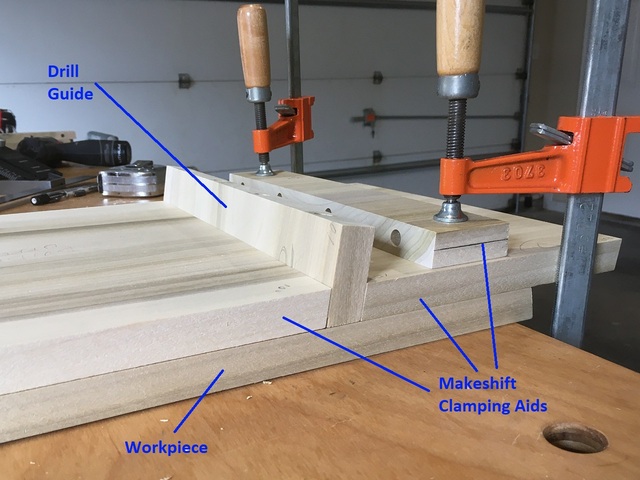

I used a variety of techniques for holding the drill guides in place as I drilled. I used cutoffs, other parts, or sled insert halves with matching angles as makeshift clamps.

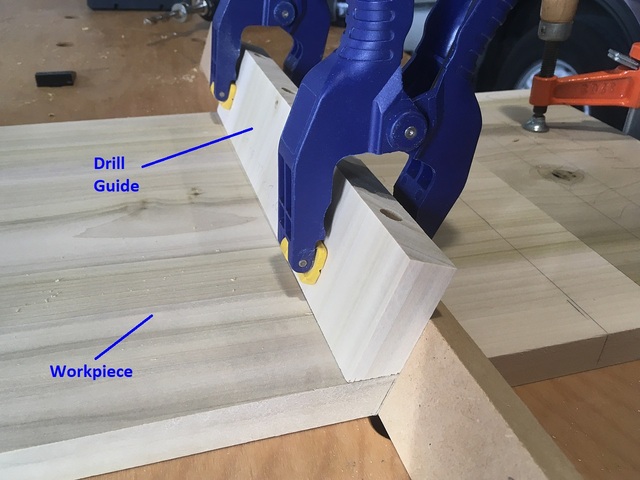

For the faces of narrow parts, I sandwiched the part between a backer and the guide and drilled from the side of my bench, using hand pressure to keep the part from lifting off the bench.

For holes on the ends of long parts, I pushed a sled insert half against the end of the part and clamped the drill guide to it.

For holes in the interior of long parts, I trapped the guide between scraps.

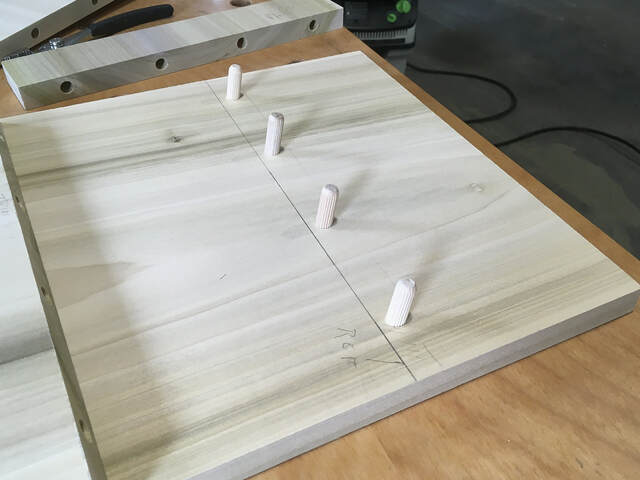

It took several hours to drill all of the dowel holes.

With just two dowels in each joint, the parts fit together securely enough to hold the case together in an upright position.