Eric - the "Loft"

in over 3 years

Segment Gluing Jig. #4: Some finishing touches

This is

part 4

in a

4 part

series:

Segment Gluing Jig.

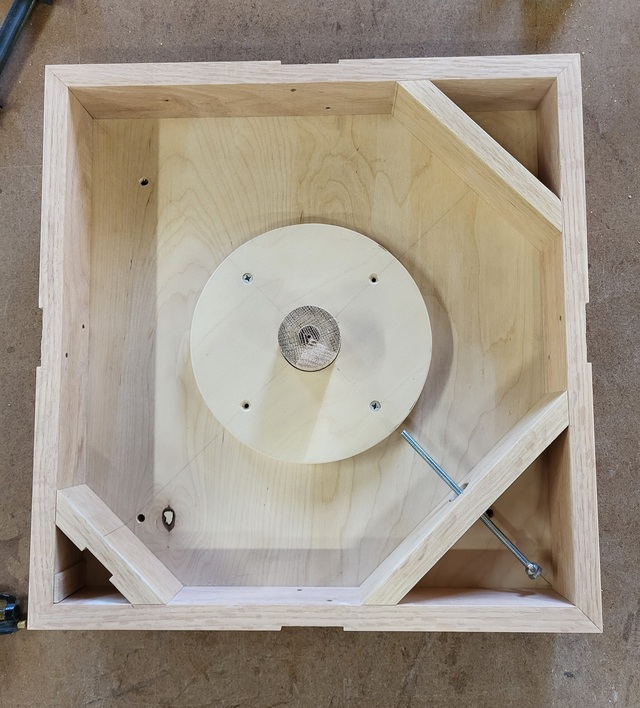

I did a little sanding on the interior pieces and glued up the frame and added a few nails with the nail gun. Then added the support blocks in the corners, screws only. I also set the post, which took a bit of work to get it plumb and having the bar parallel to the turn table. Done.

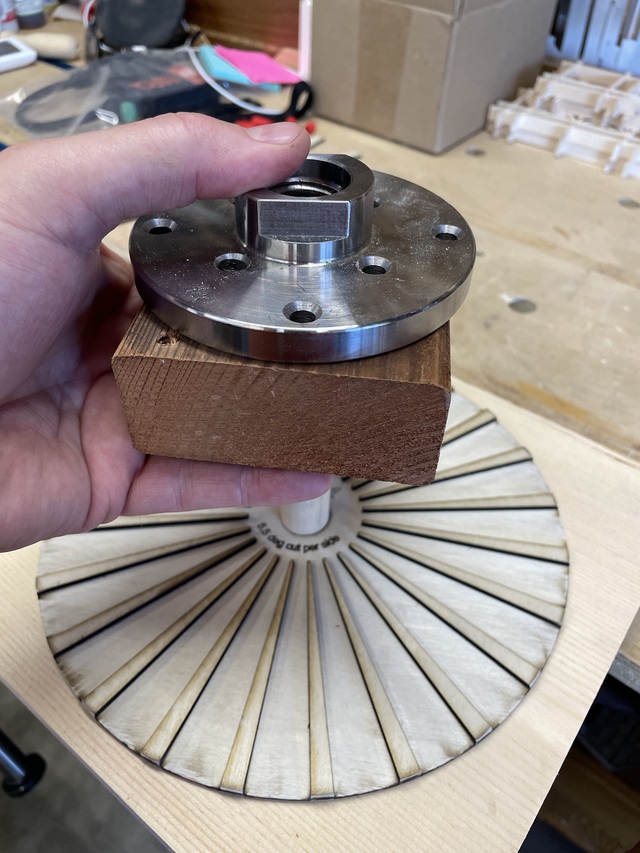

I also took the time to trim the bar to length and set it up. Then attached the large circular protractor, hanging a plumb bob from the end of the bar. I will admit it is off a tad bit 1/32nd.

Attached the 4 legs (lost a small bolt, frisky little buggers) Screwed the press plate which goes on top and inserted the clamping jig.

And

There is also a plate with a scribe line to to set the angle. I think I need to take this off and paint a black ring around the perimeter.

After doing some tweaking tomorrow I think this will work for my intended purpose. I managed to meet all of the parameters that I was shooting for. I will try to get a project posting in the next few days.

Thanks for reading and following along on this build, comments are always welcome and appreciated.

Main Street to the Mountains

28 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

The piece at the top will slide down and allow me to apply a little pressure to the glue joints, again in theory. I will have to remove the bar to slide the clamp down to the layer of rings being glued.

Main Street to the Mountains

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Can't wait to see it in action.

Petey

David

Petey, thanks. yep, open segments, been wanting to give them a try again and see about patterns.

David, thanks. I found the large protractor online, thing it will work as intended.

Main Street to the Mountains

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Main Street to the Mountains

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Oldtool, thanks. Needed the precision to make it work correctly.

Main Street to the Mountains

1/32" is pretty darn amazing for wood with all the attachment points involved. Could also be a local gravitational or magnetic anomaly.

Your bench is level and no beer caps or cookie crumbs you forgot tho clear away right?

Main Street to the Mountains

.................. John D....................

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Main Street to the Mountains

.................. John D....................

Main Street to the Mountains

I built a little stand with a 7/8” dowel sticking up out of the center. I figured I can turn a shallow 7/8” recess into a bowel base being held by a chuck, then use the dowel to center the chuck over the gapped segment plate. Pushing down on the chuck slides the dowel down (it’s just press fit into the base) and keeps it centered so it lands properly on the plate holding all the segments. It’s kind of the poor-man’s version of the Stomper thing that the guy made with the pop-up sprinkler. No idea how it’s gonna work, but the theory seems sound.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Main Street to the Mountains