RyanGi

in over 3 years

More from RyanGi

Plane Iron screwdriver

__________

Just a quick shop tool build.

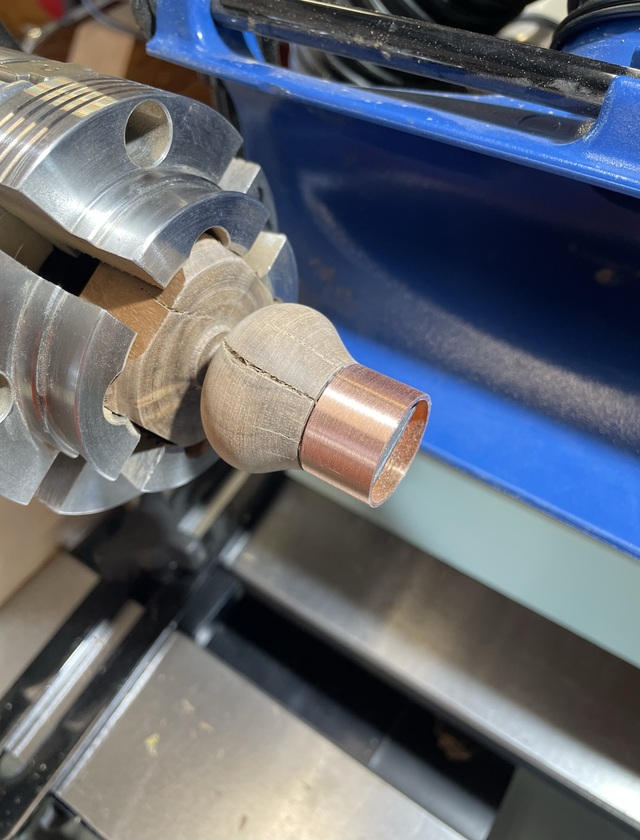

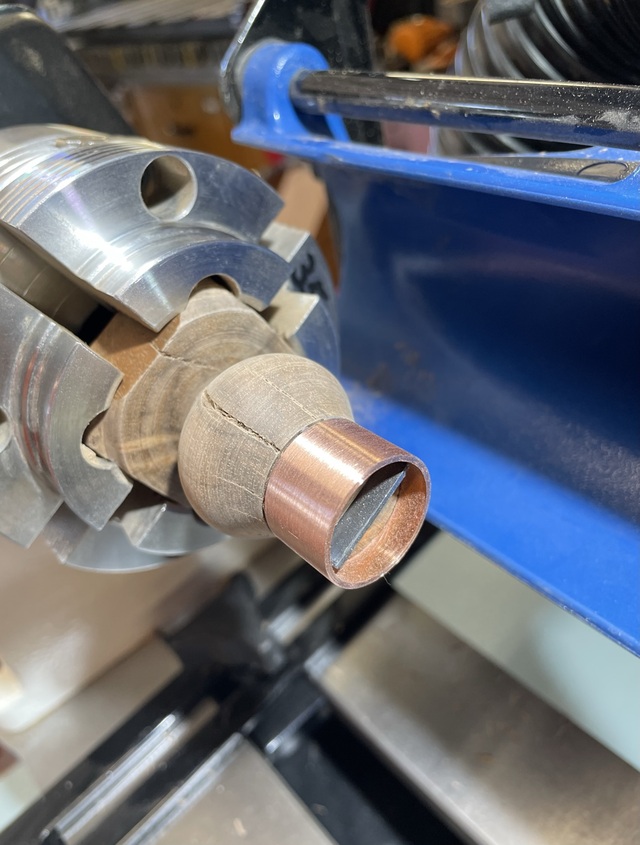

I've been meaning to make a plane iron screwdriver for a while and just never found time for it. I had the lathe out to finish some pens, and had some down time while I was told to be out of the house while SWMBO went after it with a deep cleaning. So, I chucked up a scrap chunk of walnut and roughed this out. Unfortunately, I found a big ol' check a bit under the surface. Undeterred, I soldiered on…after all, this is just a shop tool.

I turned down a small section of copper pipe, clipped a piece of scrap steel, and fitted it all up. Sanded to 600, polished with a bit of Dr. Kirk's, then finished with some friction polish on the lathe. Sprayed out with a couple coats of lacquer for durability, then some Renaissance wax.

I cut a couple nicks on the bushing with a triangular file, just enough to know where the end of the blade is up under that bushing.

Not a bad way to kill an hour. And I got a new tool out of it!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

18 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

MosquitoMade.com

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Excellent way to preserve those slots!

Well done Ryan.

Main Street to the Mountains

I blame the dogs of course

Ha! That’s awesome…

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Petey

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Knowing how to use a tool is more important than the tool in and of itself. - Ron Aylor

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".