LIttleBlackDuck

in over 3 years

More from LIttleBlackDuck

Dice Puzzle

Approaching Xmas, this is the ideal time to use up some scraps and for once, this puzzle is better suited to solids rather than laser cut MDF.

Solution by layers:

Hot on the tail (sizzle) of my previous puzzle post, this one was fabricated to confirm there is more than MDF in my workshop's wood pile and my laser is not necessarily my primary operational tool.

This puzzle was also plagiarised from here (you might have to navigate to the Mechanical 3D puzzle plans screen). All relevant plans, documentation, including solutions can be found on the appropriate page.

The fart has dissipated, much like the congregation, but the lingering subtleties still remain.

While on this topic of those small explosions between the legs,

Q. Why does a fart smell?

A. For the benefit of the deaf!

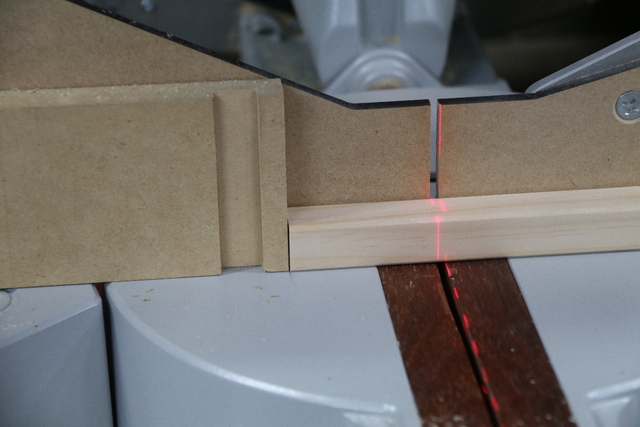

Started off as a very simple build… Sliced some slivers of 19mm non-boomerangs from a piece of 19mm x 42mm pine boards…

Q. What do you call a boomerang that doesn't come back?

A. A stick!

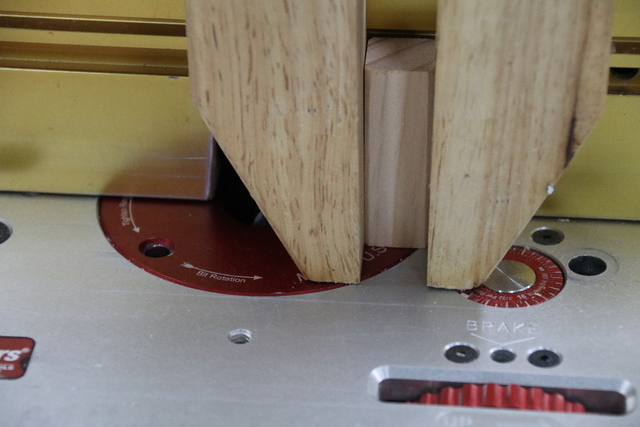

Chamfered the resultant stick on all four edges at the router table,

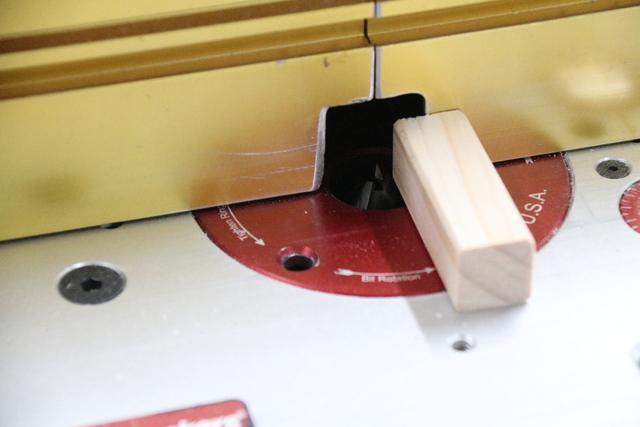

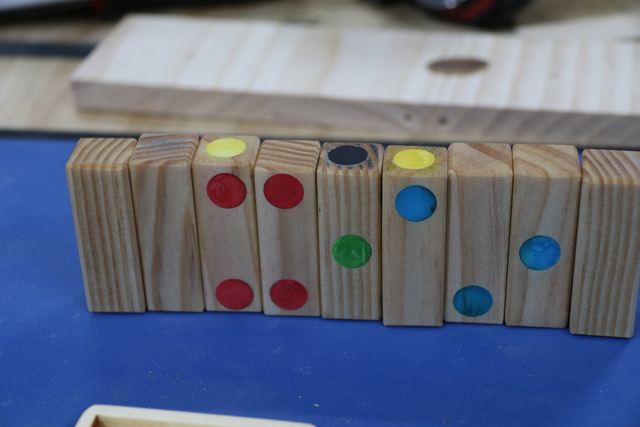

Set up a stop block and cut 18 x 57mm smaller sticks (2 sets) to permit 3 layered stacking of the 19mm x 19mm kindling (smaller sticks).

Don't know what possessed me to try to chamfer the ends using a wood handscrew,

Not wanting to abandon my expensive hobby laser (long story for the uninitiated), decided to laser engrave the dots on the sides of the kindlings,

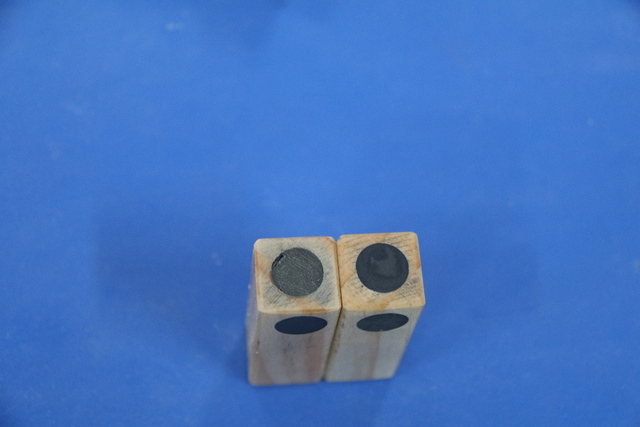

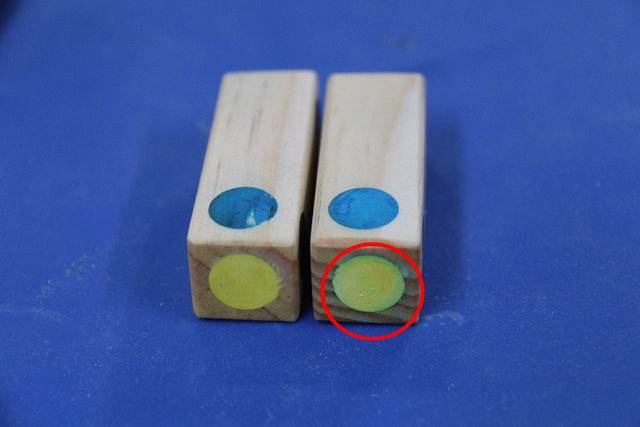

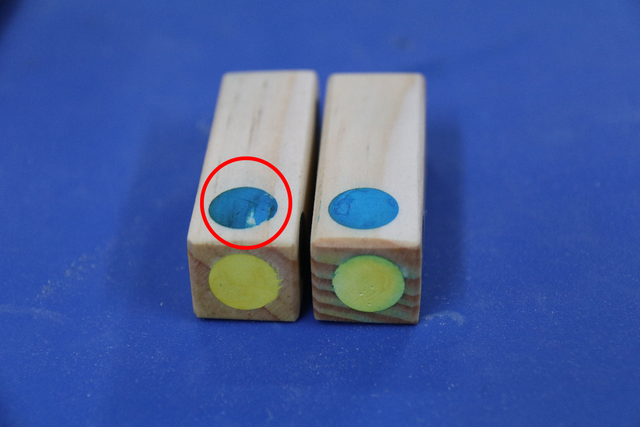

Transferred the "end dot" creation to the drill press and used a pen blank centering jig to drill the 12mm hole,

Filled the holes of one set with all black (ebony) wood filler and for the other set, mixed up some colours for each dice side's number combination,

- 1 white.

- 2 yellow (mixed).

- 3 blue (mixed).

- 4 red (mixed).

- 5 green (mixed).

- 6 black.

The sides were sanded on an upside down mounted ROS,

Couple of oopsies in the fabrication:

The black spotted puzzle was surprisingly more difficult than first envisaged. The coloured one was easier once you lined up your ducks (colours)

The fact that opposite sides add up to 7 can also assist in solving the all black dot version and further simplify the coloured.

There is a Covering video covering video about the assembly of my three latest puzzles,

The following is a link to all my puzzles stored on the cloud.

Each puzzle may contain all or some of the following folders;

For Corel (not C125) and SketchUp, backward versions may be made available on demand if not present and documented.

(Not all puzzles have been tested and published.)

If your first cut is too short... Take the second cut from the longer end... LBD

11 Comments

Main Street to the Mountains

Eric - the "Loft"

commented less than a minute ago

new

Nice Puzzle, can be a good learning tool for the little ones. numbers and colors.

Main Street to the Mountains

But a bugger in a game of Monopoly.

When it comes to learning,

this one seperates the men from the boys.

I gave these out last Christmas... many are still unsolved... at least by those determined not to look at the solution.

Be a great exercise for the WORDLE boys (and gals)...

If your first cut is too short... Take the second cut from the longer end... LBD

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Main Street to the Mountains

Dutchy

commented 6 minutes ago

new

You see LBD people are loving puzzles, and especially yours

Personally, I like them and like telling people about them... they exercise the little brain I have left.

I keep posting as you can lead a horse to water... gotta teach them to drink and not just swim in it.

If your first cut is too short... Take the second cut from the longer end... LBD

My life is already full of puzzles, like where are my keys and wallet.

There's roosters laying chickens,and chickens laying eggs... John Prine

hairy

commented about 7 hours ago

new

2 thumbs up on a complex build, a puzzle itself.

My life is already full of puzzles, like where are my keys and wallet.

You think you've got problems hairy... what is a key or wallet!

If your first cut is too short... Take the second cut from the longer end... LBD