LIttleBlackDuck

in over 3 years

More from LIttleBlackDuck

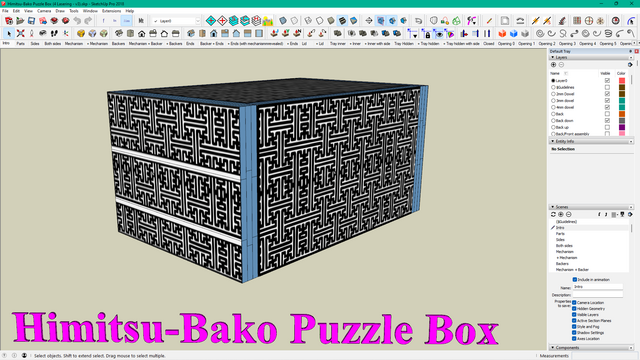

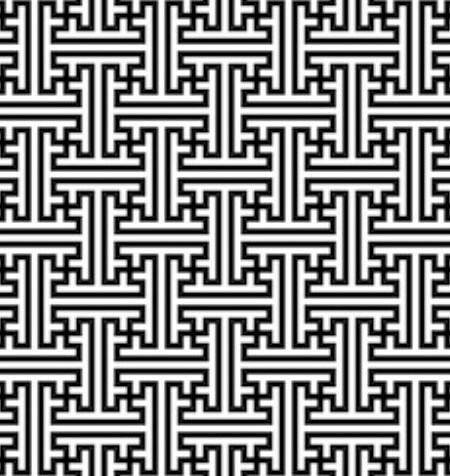

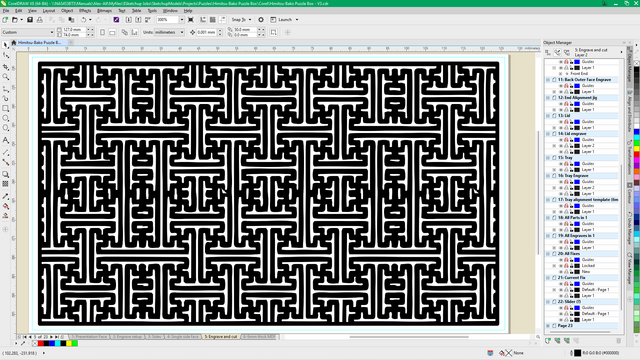

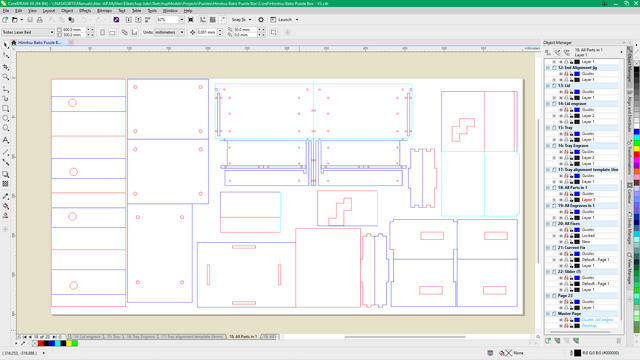

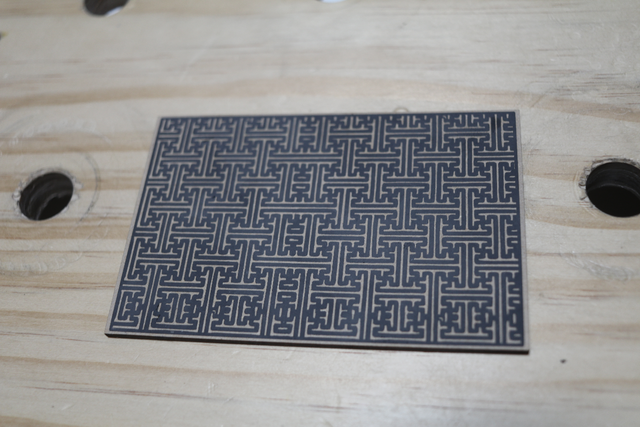

Himitsu-Bako ("Japanese") Puzzle Box.

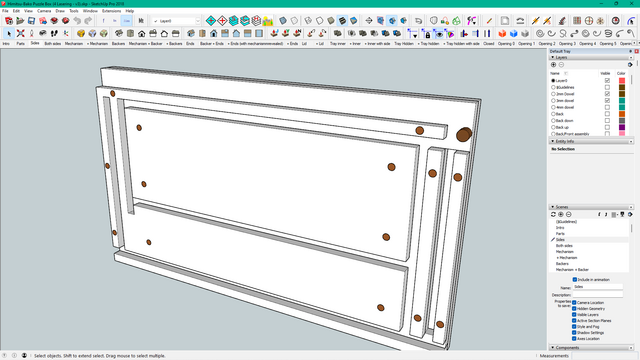

(sorry but the camera refused to shine)... Care was taken to avoid buffing areas that are still to be glued and once finally assembled, the overall box is then again passed through the 3 “grits” of waxes.

(pls, pls, check it out… just to boost up my stats.).

If your first cut is too short... Take the second cut from the longer end... LBD

35 Comments

Martin Sojka, Maker of Craftisian

May you have the day you deserve!

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Very cool box, I like how you did the inlay with the black.

Nice video, Nice box.

Mike

Loved your video

And I look forward to the surprise puzzle that you are left with - what to do with the leftover pieces!!!

Will it be a wall hanging? A doorstop? A new box? Or … ?

JAGO - just a grandma’s opinion

That is one sweet surprise puzzle box!

Dennis Zongker

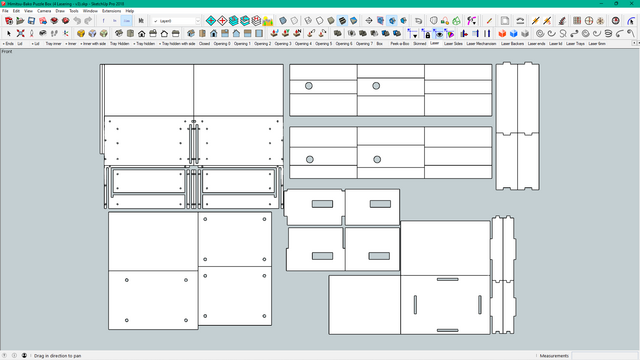

I just use a laser cause it's repeatable and I've got one to spare (long story).

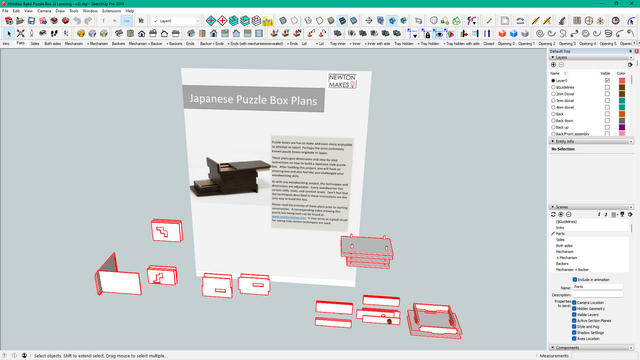

Having the "measurements", layout and solution, puts them in the capabilities of most woodies.

Most of my files are available (all my stuff is free of charge) on my cloud storage,

https://u.pcloud.link/publink/show?code=kZMbnlkZ59shdjNzWIFxphFqI9eWDVoNDb3y

but I'm keeping that a secret for future publications here....shhh!

If your first cut is too short... Take the second cut from the longer end... LBD

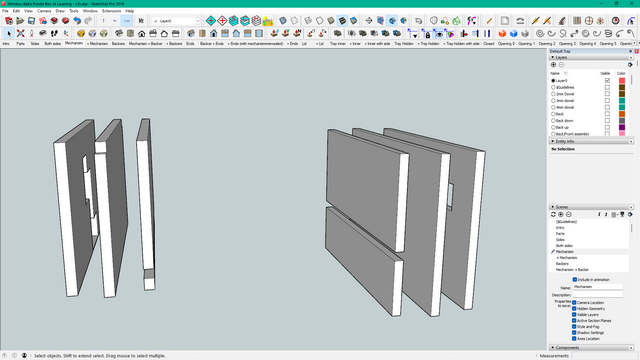

I made a video of the trials and tribulations of assembling this box.... it craps on a bit but nowhere as long as it took me to glue/assemble the box. Many mistakes made, however, ironed out to come up with a more viable design.

If your first cut is too short... Take the second cut from the longer end... LBD

エボニー ティンバーメイトを使っていただければ幸いです。Soshite, ahiru wa tobanaito dare ga iimasu ka... Nante subarashī kangeideshou. Ebonī tinbāmeito o tsukatte itadakereba saiwaidesu.

Regards Rob

If your first cut is too short... Take the second cut from the longer end... LBD

Regards Rob

Looks like a punishment worse than the death penalty will inevitably be introduced, no matter what the result.

If your first cut is too short... Take the second cut from the longer end... LBD

Albert