crowie

in over 3 years

More from crowie

Not quite a toy but ready for toys to play upon!

The young builder & his wife across the road had a little boy 3 months ago so the house has to be rearranged ready for the little blokes pulling up and playing on and with everything. I've already given them a couple of smaller toys ready for him to enjoy playing with.

They had an old coffee table in their lounge room that wouldn't have been safe for the little blokes exploring.

Josh had recently done a reno on an old house and saved all the the old Aussie hardwood framing, then asked "do you think you could make us a coffee table".

I needed something to keep busy as our daughter was in hospital with pneumonia just 8 days after the arrival of our sixth grandchild, a boy, Marcus.

Her hospitalization was 4 weeks including major surgery to clean the lung, it's been a difficult couple of months for all especially her who is now on a long recovery.

The table was a welcome distraction and steep learning curve as Josh then said he'd like it as an "end grain" table...WOW!

I de-nailed the old Aussie hardwood, put it through the thicknesser, then glued the boards to together.

The next task was slicing the lot into 40mm strips on my 10" Bosch Contractors Tablesaw [it didn't like that process] before again another glue up.

The glued end grain pieces weren't quite wide enough so I added an old fence rail to the sides for extra width.

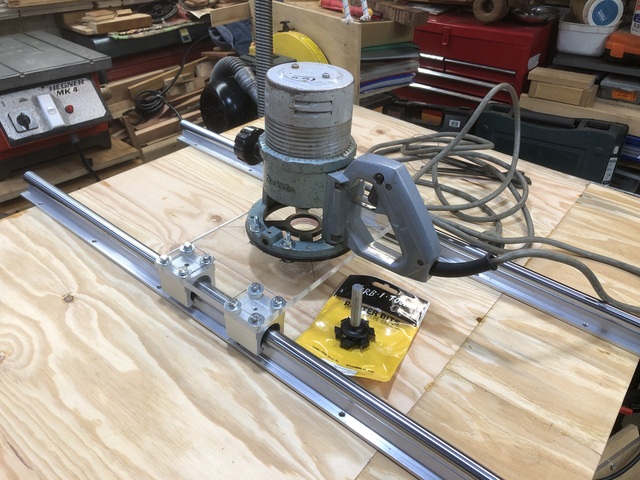

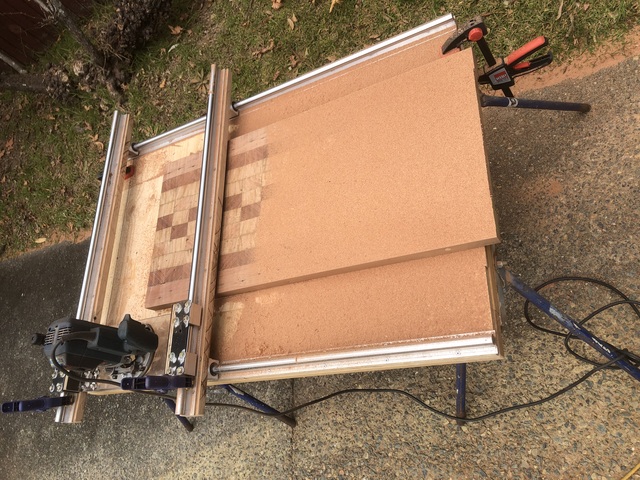

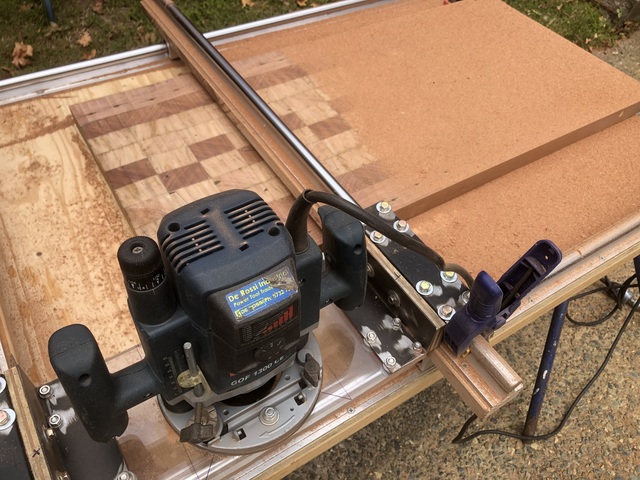

The whole board then needed to be surfaced and made flat so onto eBay for some "linear rails" to make up a router sled.

Mean while the cracks, splits, holes and defects were filled with Ice Epoxy Resin plus the smaller holes with Starbond CA.

First attempt, the old Makita D Handle router [from my passed father-in-law] collet failed but "spares not available, bother!

I purchased a new secondhand Bosch Professional 1300W [Made in USA] router and along with the Carbitool surfacing bit got the table flat [just 3.5hrs].

[Thank you Ian for your advice]

The next process was to add a skirt/border around the whole table which was glued, screwed and plugged in place before hours & hours of sanding.

I was fortunate enough to score the purchase of a beaut secondhand Bosch Professional Turbo Sander from a forum member to assist with this task.

[Thank you Peter]

AND FINALLY the table is ready for 4 coats of my homemade wipe-on-ploy along with sanding between coats plus a top coat of Satin Poly to finish.

What an effort for a toymaker as it took up all of my shed and more for nearly 2 months but a top learning experience.

Cheers crowie

PS - Old Aussie Hardwood is beautiful but some damn hard & heavy!

Life’s Good, Enjoy Each New Day’s Blessings

24 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Main Street to the Mountains

awesome table crowie. what a cool thing to do. they had to love that table ! hey, old is that first router ?

Thank you Pottz.

The old Makita Router would have had to be over 40yrs old.

I rebuilt it twice with new bearings and brushes.

A local woodworking mate said he had the same router with a dud armature so I gave it to him to make one from two.

Life’s Good, Enjoy Each New Day’s Blessings

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Looks like you made quite a few purchases for a gift... very generous. Sounds like you bought the linear gear for this project. Is it and/or do you plan to make it more height adjustable (outside the router plunge capacity?... if that's what you are depending on).

I'd be interested on where you bought the linear gear (local???) and how much? Most sites I found didn't quote prices. I'm not mechanical enough to search by name... I depend on visual pictures.

Details/build of that leveling setup could be a good subject for a blog.

...... my 10" Bosch Contractors Tablesaw [it didn't like that process].....

If your first cut is too short... Take the second cut from the longer end... LBD

May you have the day you deserve!

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

That sure was a mammoth task...but those sort of jobs are very rewarding and give us a great experience in wood working.

Excellent Project Peter.......Regards......Cliff.

Looks like you made quite a few purchases for a gift... very generous. Sounds like you bought the linear gear for this project. Is it and/or do you plan to make it more height adjustable (outside the router plunge capacity?... if that's what you are depending on).

I'd be interested on where you bought the linear gear (local???) and how much? Most sites I found didn't quote prices. I'm not mechanical enough to search by name... I depend on visual pictures.

Details/build of that leveling setup could be a good subject for a blog.

The costs were reduced/refunded after some shipping damage and delivery issues.

I originally mounted the router on top of the bearings on the rails but it was way too high so I had to make a “Z” attachment mount. It gives me nearly 50mm of working thickness.

The base is 5/8” ply on a braced 4x2 frame and jolly heavy.

On the “gift” suggestion, the young builder is giving me some of his time to convert a bifold door unit into a trifold door unit between our dining room & sunroom to accommodate the now larger family gatherings.

Life’s Good, Enjoy Each New Day’s Blessings

Well done, Peter, that has some beautiful grain and patina. You are now a seasoned craftsman who has moved on from the realm of toys.

Life’s Good, Enjoy Each New Day’s Blessings

Cheers

Kerry - Working with wood, the smell the feel, is such a joy, its a meditation of sorts.

As for the end grain table top, super job, looks great.

Cheers, Jim ........................ Variety is the spice of life...............Learn something new every day

Ron

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

TimV, "The understanding eye sees the maker's fingerprints, they are evident in every detail, leave Fingerprints." James Krenov

The Other Steven

Life’s Good, Enjoy Each New Day’s Blessings