HokieKen

in over 3 years

More from HokieKen

2023 BeerBQ Swap package

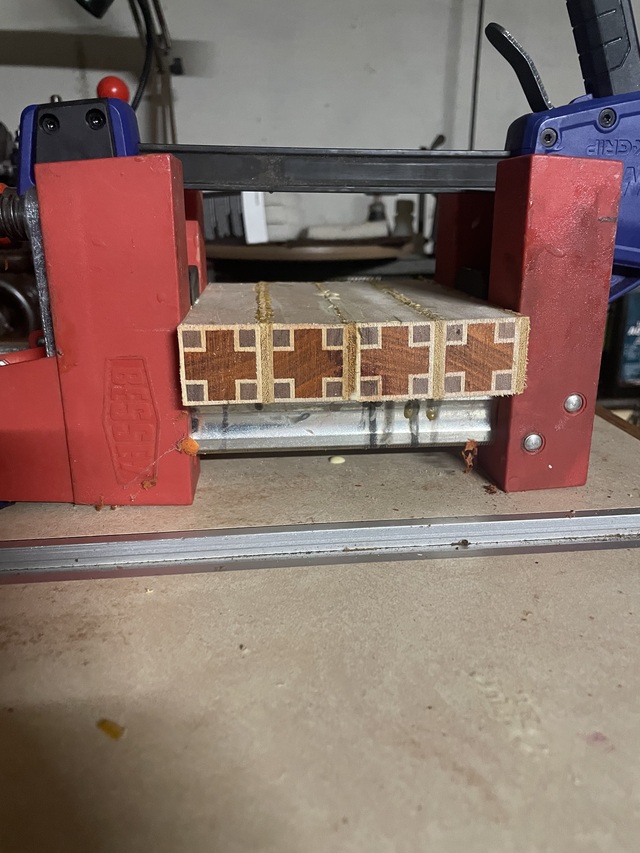

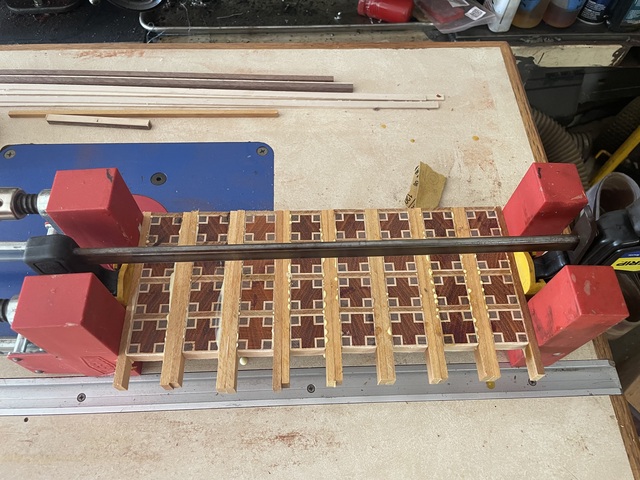

So after some glue ups:

And planing:

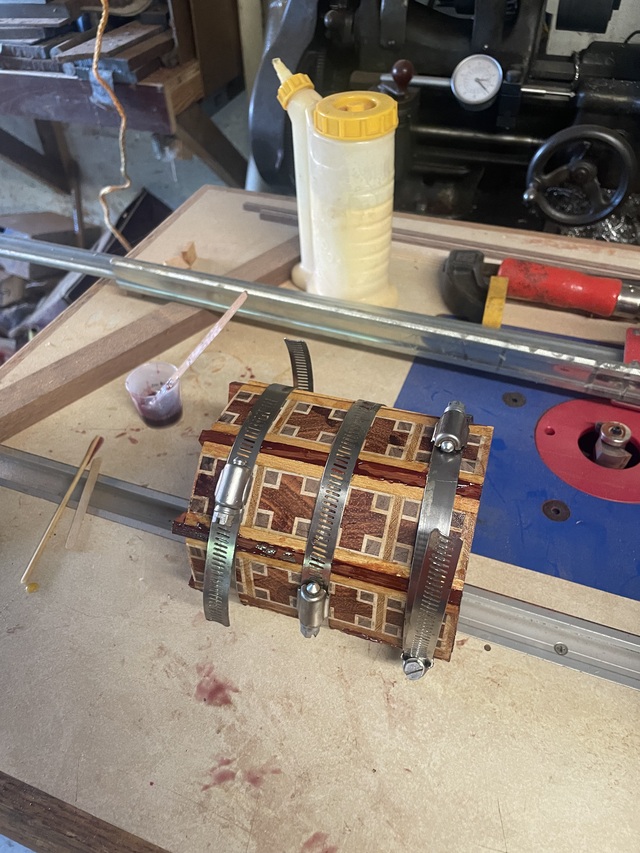

And gluing:

And planing:

And gluing:

And planing:

And gluing:

I was finally able to start turning.

And eventually finish:

I was really happy with the final result. Though I wish I had used some denser woods than the Maple and Walnut in the cross segments. I had a lot of tearout in the endgrain on those pieces since they were completely dry. I had to stop after each session and fill in about 100 tiny holes with CA glue. But eventually I got a good finish on inside and outside.

The woods used are Paduak, Walnut, Maple and Osage Orange for the cross segments and Paduak and Osage Orange for the vertical dividers. The top and bottom pieces are also Osage Orange. The finish on the inside is a clear food safe epoxy that makes the cup waterproof and able to be used with cold beverages without damage. The outside is friction polish because I like the way it looks and feels. It will also allow a film finish to be applied over top of it if Ryan wishes.

I was a little worried that the cup would be too large without a handle but I could hold it comfortably and liked it a lot without a handle so I left it as-is. I needed to send Ryan something to test the epoxy seal with so I sent these along:

I also sent Ryan a toothpick holder in case some wood pieces broke loose and got lodged in his teeth.

I hope Ryan enjoys his package half as much as I enjoyed the one I got from Steve Rasmussen 😎

40 Comments

Next time you do something with a pattern, you should glue up one with your logo.

"Duck and Bob would be out doin some farming with funny hats on." chrisstef

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan, I didn't take any pics but I tape off the outside top of the cup with painters tape before I apply the epoxy to get a clean line at the rim. I start by applying a coat in the bottom of the cup with it sitting upright to cure. For this bottom coat, gravity does the work of ensuring it's level and even. Then I put the cup back on the lathe. I brush the epoxy on in thin coats and until it's had time to at least partially cure (a few hours) I let the lathe run on the lowest speed. This is to keep it even and run-free. It's gonna spray epoxy at first though so make sure there's nothing in the line of fire. Especially you... After it's tacked up enough that runs aren't as big of a concern, I pull it off the lathe and set it upright to finish curing over night. That way if I'm wrong and it does still flow some, it'll run to the bottom and even out there instead of pooling on the sides. Rinse and repeat until everything has good even coverage. I think I ended up with 4 coats on the walls of yours. The low speed on my lathe is ~600 rpm. Applying this epoxy is one of the few times I wished I still had my old midi lathe. It would turn down to about 200. I could have done it on my metal lathe but I wasn't about to go spraying epoxy over there...

i gotta say even with one flake dropping out this is the best beerbq swap youve ever done. the quality of the projects just keeps getting better each year. thanks for running it my friend, see ya again next year !

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Prep and assembly look deceptively simple thanks to your photo essay 👍

Pictures of Ryan's show some nice chatoyance and the chewy beers will certainly stuff any micro-leaks.

Tooth picks look like pre-loaded bamboo blow guns, good for picking' and grinin'.

Mike

Yooper with a Drawl

Ron

.................. John D....................

No name noobie here

When one looks at segmentation, they usually don't appreciate the major effort behind it before it hits the shaping tools (lathe etc...).

After this presentation you may have scared the bjesus out of many slack newbies (and old farts), or armed them with knowledge and just watch CN get inundated by a swag of fancy cutting boards.

Assume there are no pickies of

It is pictures like this (thin stock and those dogs) that makes me freak out in using hand tools,

I always imagine turning my plane blade into pinking shears.

How long did it take you to turn those tooth picks?

Cheap and woodwortking in the same sentenc is an oxymoron!

Sooner or later I imagine you'll see a cutting board with the same pattern Corelz 😉

Anatadephorilabiomoratum (or whatever it is...) the toothpicks took me virtually no time to turn. The time I spent turning the holder was infinitely more. And the nice thing about that planing stop is that it's height adjustable. So I can set it so my blade can't kiss it 😎 The key to beveling both sides is to glue it up in halves. Then you can fudge the angle when you glue the halves together if your acute got obtuse somewhere along the line. And I'll have to take my licks and do my penance. I just looked back and I did indeed fail to take any pics of the beveled pieces prior to gluing them all together...

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

That said, great work, bud! You had a lot more pieces going together there, and did a great job.

May you have the day you deserve!

(stares intently for a very long time)

I'll take 2.