RyanGi

in over 3 years

More from RyanGi

BeerBQ Swap 2023 —-

I started by gluing up some laminated blocks to turn for handles. Mahogany with a thin maple inserts. Trying to maintain an aesthetic theme with them, they turned pretty cleanly. I lasered “Salt” and “Pepper” on the grinder handles then finished everything with Tried & True. I figured they’re going to get handled and Tried & True is easy to reapply and keep the handles looking good!

Once the handles cured a bit, I epoxied in the various components for them all.

The handle of the pizza cutter screws off so the metal blade assembly can be washed, but I wanted a way to protect it. After some measuring, I milled out a cover for it, leaving a rim around the edge and glued in some magnets to make her stick!

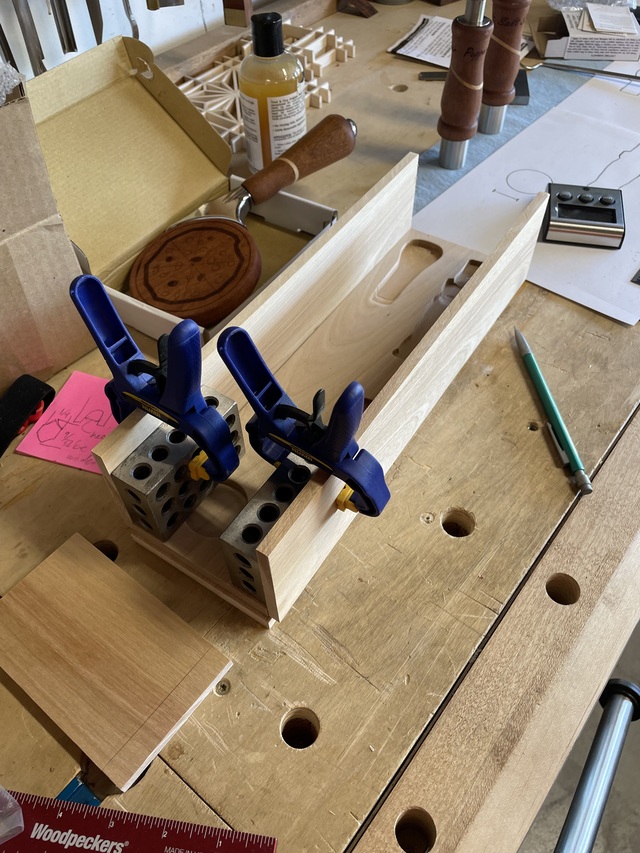

Lastly, I built a simple little recessed top box to store the grill goodies. It’s made from resawn birch, the lid held in place with magnets. The base has patterns milled out to keep the goodies from moving around too much. Because I wanted to keep the stock thin, I pinned the corners with brass rod.

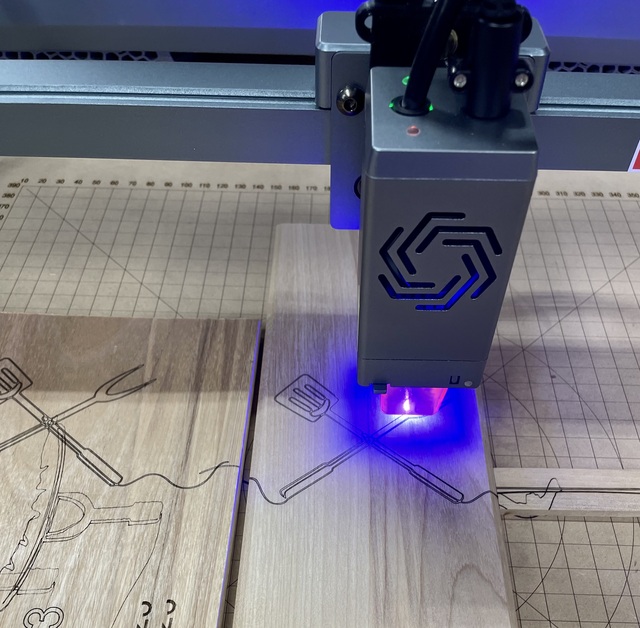

Not wanting to leave well enough alone, I set about decorating. I found a couple thin-line designs that were grill-centric for the box, and decorated up the pizza slicer cover to look something vaguely like a pizza.

The box I finished with a couple coats of amber shellac, then a few coats of lacquer. Buffed by hand.

All in all, the project finished up cleanly and I was pretty happy with it, despite a couple flaws. But, hey, it’s bbq goodies…they’re never gonna be perfect!

Last, but not least, I grabbed him a few beers from two local breweries and a couple local ciders as well. Our local beers can be a bit, creative, sometimes but most are pretty good. I tried to get him a mix of reliable favorites and some new ones to try.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

25 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Shaper, 123 blocks, laser rotary, Probably a coordinate measuring machine in the corner for QC!

Some finally crafted stuff, creative to boot!

May you have the day you deserve!

No name noobie here

A really great package man. Thanks for all the detail and for such a great swap!

And I had no idea what a CMM was until I looked it up!!

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

"Duck and Bob would be out doin some farming with funny hats on." chrisstef

We have a CMM with a 6’x10’ granite bed thats suspended on air at work. It’s in its own clean room. I actually considered hauling my workbench top in there before I mounted it permanently yo see just how flat I actually got it using winding sticks and handplanes. I never did but I’d have probably found out that I wasn’t nearly as precise as I imagined I was😉

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Ron

Do you have some sort of rotating gizmo for your LM3 to do those round S & P's?

David

One nice thing about using an Ortur rotisserie on the LM3 is that it’s got a separate plug in the frame just for that. A toggle switch jumps between the regular y-axis gantry motor and the rotisserie making it a snap to swap back and forth. You do have to do some testing within Lightburn so the software knows how many steps and at what rate to rotate the rotisserie. It’s not hard, but is a bit tedious for one-off projects. I haven’t done many burns using the rotisserie, so I’m not very adept at it but, when you need that process, it’s the

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Looks great!!!!

Regards......Cliff.