Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

LIttleBlackDuck

5504 posts

and

55 followers

in over 3 years

in over 3 years

More from LIttleBlackDuck

Hints and tips that some may not have heard of. #52: Dis_CORD in the workshop.

Hints and tips that some may not have heard of. #51: Glass Jars for those recalcitrant chems.

Hints and tips that some may not have heard of. #50: Crank Up your Tracks.

Hints and tips that some may not have heard of. #49: Defrosting Your Ice Maker.

Flowerdale – "Deliverance" on the Road.

Hints and tips that some may not have heard of. #21: Refresh the memory and Graffiti your tools.

This is

part 21

in a

52 part

series:

Hints and tips that some may not have heard of.

...

-

Anti Slip “Cookie” in your Swimming Pool.

-

Refresh the memory and Graffiti your tools.

-

Stop banging your head against your bed's head board...

...

...

- Anti Slip “Cookie” in your Swimming Pool.

- Refresh the memory and Graffiti your tools.

- Stop banging your head against your bed's head board...

...

Boys and Girls,

As I grow older, my memory barely remembers where I put down my cask-o-vino,

As I grow older, my memory barely remembers where I put down my cask-o-vino,

let alone what measurements to associate with all those tools I barely remember in the workshop…

Rather than waste RTFMing a large part of my time in the workshop, I regressed back to my school day exams and wrote “cheat sheets” as appropriate for the equation in front of me.

I previously published this at LJ on 31st May 2020 (I think… don’t fully trust cut and paste)… if you remember reading it there, you haven’t tipped over the edge… yet, but if you can’t, I suggest you get a big box of markers.

Recently (yesterday, as I draft), I needed to rely on one of the hints and decided to make a supplementary video of how I tackle left handed threads on “dual spindled” bench grinders,

I cover a lot of individual items I’ve tagged in my workshop below, however, in my defence, there so many as I keep forgetting what I had already included.

______________________________________________________________________________________________________________________________________________________

Boys and Girls,

If you suffer a case of forgetfulness and remember how to read, continue, otherwise…

If you suffer a case of forgetfulness and remember how to read, continue, otherwise…

hmmm… I forget… come back later… things might have changed.

I am getting old quicker than birthdays seem to come around. While Uncle Alzhi hasn't caught up to me (yet), I'm a guilty advocate of,

I am getting old quicker than birthdays seem to come around. While Uncle Alzhi hasn't caught up to me (yet), I'm a guilty advocate of,

- Hate to RTFM.

- Loathe to play what-ifs with a chain of allen keys or wrenches/sockets.

- Continually skin knuckles or strip threads in trying to twist things the wrong way.

- Cause ill-rest in the household with the proliferation of prolonged, profound profanities.

- … and many more shortcomings that I care not to remember.

If you can relate to any of the above symptoms, salvation is at hand… with the dexterous use of a texta (sharpie in Yankee speak)…

There are far too many things to concern oneself in the workshop than trying to remember/recall that fine print in the bloody manual that no one ever needs or bothers to read, until the book can't be found and you have all 3 hands full of activity needing immediate attention.

Now this revelation is not in writing instructions on the back of your hand or on the forehead (even if you can read backwards), but to use a texta to deface your tools in an endeavor to refresh your memory.

I have gone around and written handy tips onto my tools with a texta and refresh it whenever it starts to fade/wear. These tips can be in the format of a number, a word, a full paragraph or even a song.

Some may think I have to be a scatter brain or mentally challenged to have to write these "instruction", that I may be, however, all I will own up to is that with all the different machines in my workshop, it's another variable I don't have to fret over… my tools, my shop, my rules and my lack of memory…

Here is a collection of my cheat sheets to give some ideas to get you started…

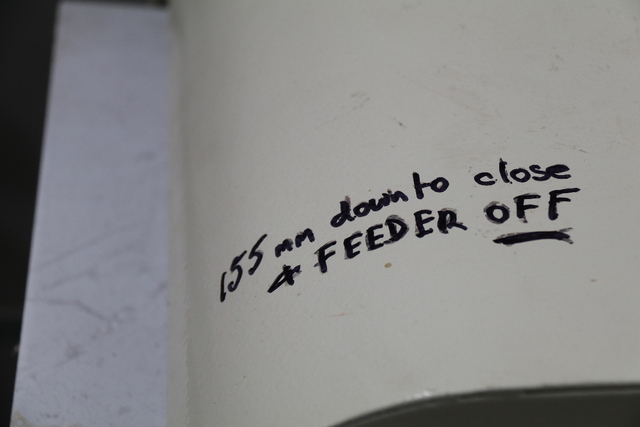

Reminder to lower the table to a specific height for function change on my jointer/thicknesser combo,

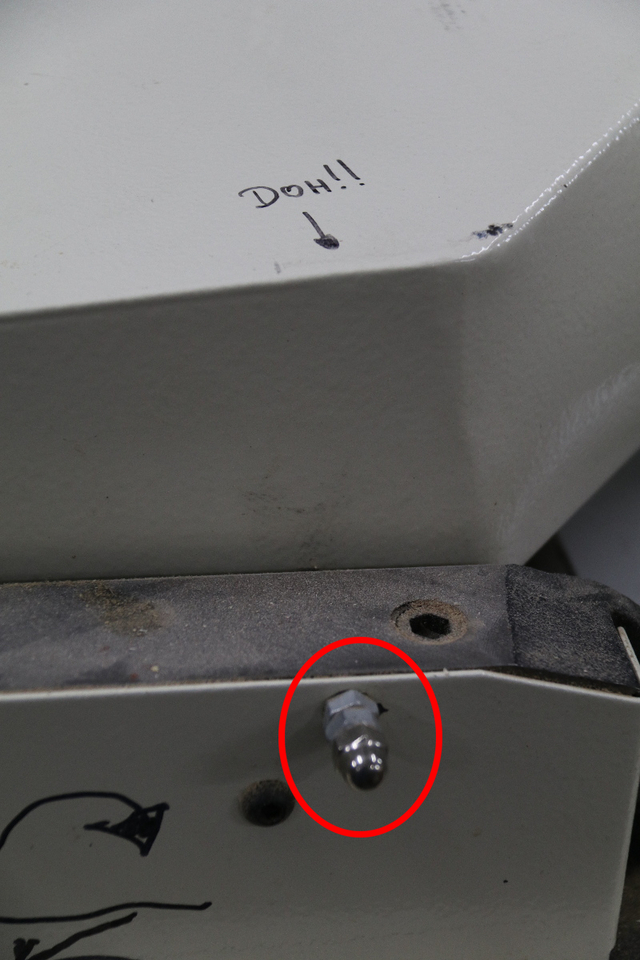

and an around about way, to pull the plug to flip the lid,

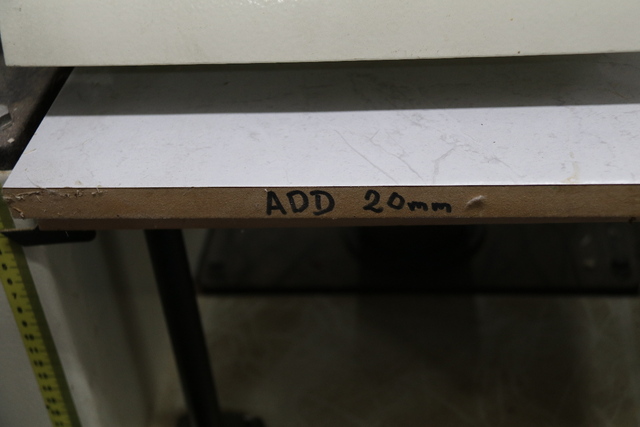

raised table compensation for the thin stock sled (actually you need to subtract and not add… but, I already know that),

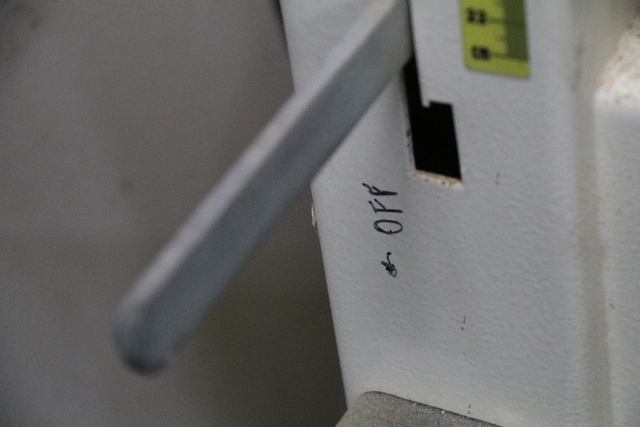

and indicate the lock position for feeder,

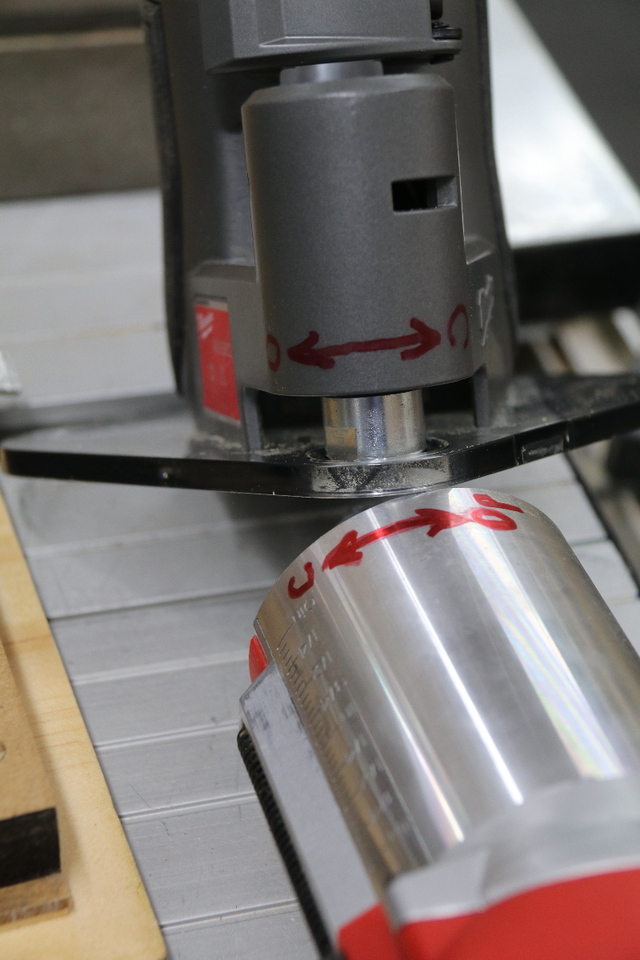

Even brand new tools get a tag for open/close direction of collete,

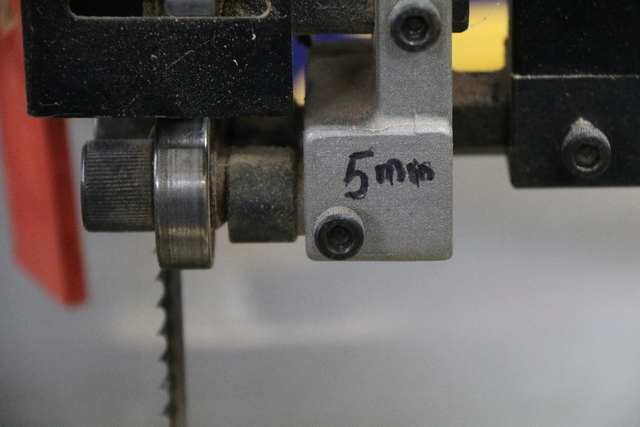

Allen key size for bandsaw bearing adjustment,

and the bandsaw's fence adjuster rotation direction for the away direction,

Drum sander Up/Down rotation direction,

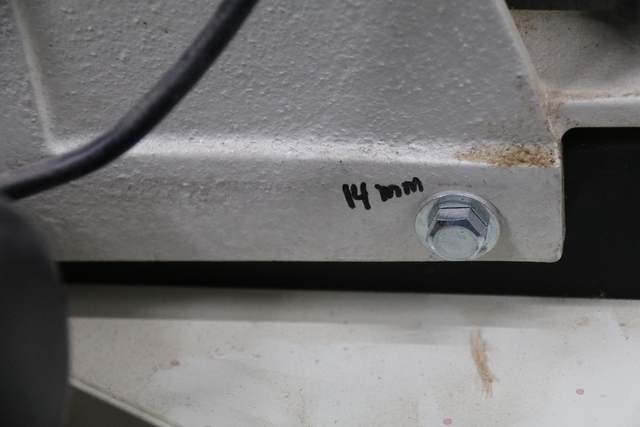

Spanner size for drum sander bolt head,

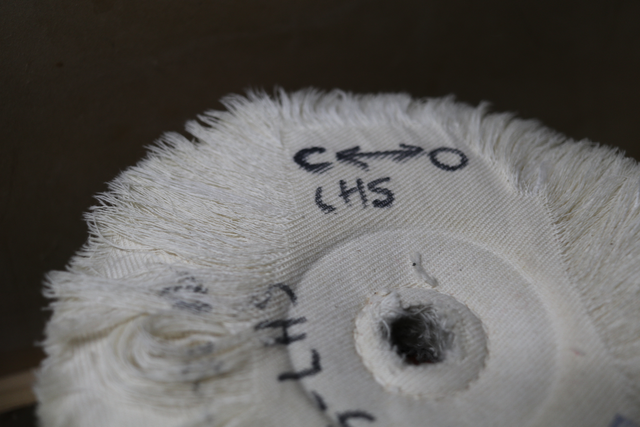

Spindle sander release direction. Diagram indicated the rotation of the attachment not to be confused with the spindle… remember it's a left hand thread,

I have 3 buffs for my 2 wheel slow speed grinder, so each buff could finish up on either wheel depending on order of change. As the left hand spindle has a left hand thread, marking the side the buff is oriented makes undoing the nut a 1st. hit execution.

The markings refer to the outside facing of the buff… RHS mount,

LHS mount,

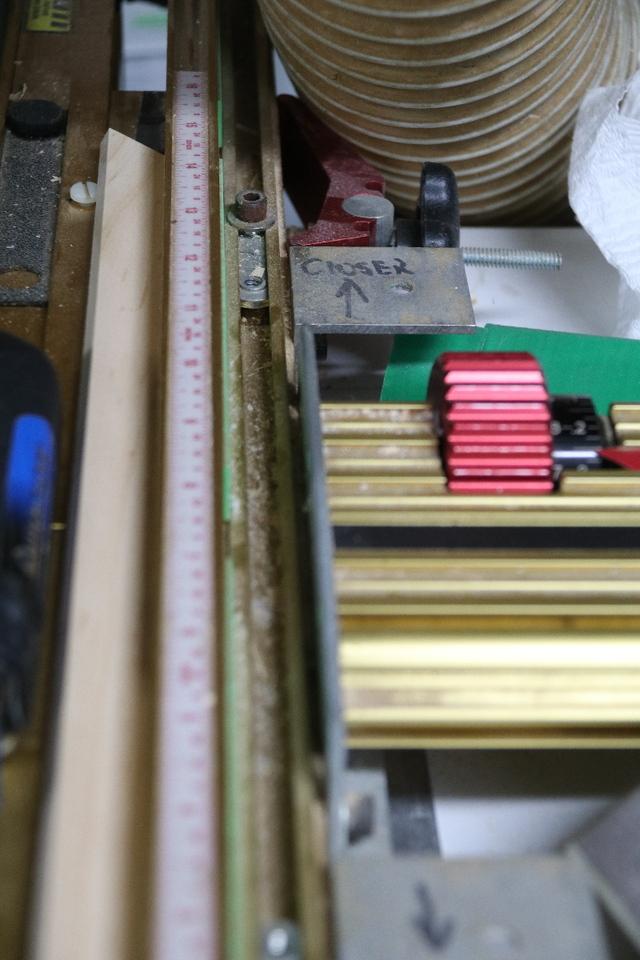

Direction of the adjustment wheel for my router table's Incra LS positioner… bit away from fence,

the other way, closer to fence

Lathe chuck open/close rotation,

Locking nut size for my lathe extension mount,

While the allen key size was written on my disc sander, this magnet mount with a spare key save me a walk to the key rack,

Even the Fe$tool gets two tags (even though the spindle lock has directional arrows),

The Ryobi trimmer gets the hinge side marked for base mounting. Can be mounted either side, however, the wrong side interferes with thumb placement during operation,

The shop vac is in auto mode 99% of the time, however, the markings are on the front hidden from obvious view,

I have replaced the locking bolt on my drill press raiser handle by a ratchet spanner. Directions takes the conjecture out of operation,

My Bessey gear clamps can be confusing depending on orientation, no need for a 50-50 chance of correct direction regardless of orientation.

Dymo labels as black texta didn't show too well on black plastic..

I have two mitre saws feeding the one shop vac,

I have two mitre saws feeding the one shop vac,

swap this laser cut/printed sign to identify saw the vac is NOT attached to,

Even the laser gets a prompt for replacement after the lens is removed and cleaned,

and a prompt for software table height settings for 3mm and 6mm MDFs respectively,

There are more but I'm sick of typing and running out of sharpies.

Become an Tagger and start tagging... just leave that texta at home if you decide to walk to the bottle shop.

PS. Once you start tagging your tools, somehow you tend to remember without the prompt.

Glossary:

Become an Tagger and start tagging... just leave that texta at home if you decide to walk to the bottle shop.

PS. Once you start tagging your tools, somehow you tend to remember without the prompt.

Glossary:

- texta... sharpie.

If your first cut is too short... Take the second cut from the longer end... LBD

7 Comments

I have done this on a few things but after reading this I think I will be doing it on a lot more adjustment locations. Thanks for the hints. Mike

All good stuff Duck.

I did the "up" on an early woodpeckers router lift (before woodpeckers bought the item) they have since up "up" on the lift base.

I did the "up" on an early woodpeckers router lift (before woodpeckers bought the item) they have since up "up" on the lift base.

Petey

done this on a few items. Cover on the side of the table saw has all sorts of "hints" on how to remove.

Ron

Ditto, plenty of things around the shop with ancillary info added 😊

Still need to do the Incra router fence. The micro adjust knob works counter to the way one would expect.

Still need to do the Incra router fence. The micro adjust knob works counter to the way one would expect.

Nice tip!

GR8 TIPS ALEX 😍😎

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

Thanks all...

Sorry for the late reply... had to wait till this morning when I looked in the mirror to read the note I left on my forehead to reply to comments.

Sorry for the late reply... had to wait till this morning when I looked in the mirror to read the note I left on my forehead to reply to comments.

If your first cut is too short... Take the second cut from the longer end... LBD

More from LIttleBlackDuck

Hints and tips that some may not have heard of. #52: Dis_CORD in the workshop.

Hints and tips that some may not have heard of. #51: Glass Jars for those recalcitrant chems.

Hints and tips that some may not have heard of. #50: Crank Up your Tracks.

Hints and tips that some may not have heard of. #49: Defrosting Your Ice Maker.

Flowerdale – "Deliverance" on the Road.