Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Craftisian Blogs

view blog series

This is a dresser made for a friend years ago when I was first becoming serious about woodworking. It is made out of a matched pair of 10/4 claro...

Since my shop is currently buried under about 1600 loose parts of a classic (read that as 45 years old) motorcycle that I am restoring, I do not ...

Speaking of nails… looking through my late father’s inventory for something short but kinda substantial. Found these.

[C4C02976-0CAD-4E10-A71C-7DF...

Boys and Girls,

These type of folding hinges,

[01.png]

seem to be a popular addition in workshops for outfeed tables

[02.png][03.JPG]

inside/out...

Due to the base construction, there is now a pair of enclosed compartments in the base which I wanted to be able to access. There were two ways th...

As I mentioned earlier, given the desired cart height and the max height of the shelf (dictated by the tallest tool), I was concerned that the late...

While I was working out the details for how to mount the casters, I spent some time finishing up the rotating platform. I made the fixed and slidi...

With the CNC cart completed, I could get back to working on the flip cart. I had purposely delayed work on it because I was struggling with part o...

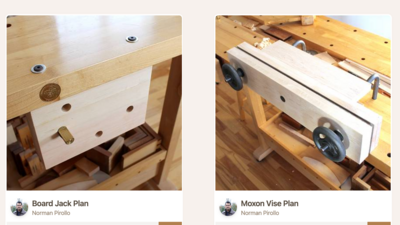

I am happy to invite you all to our brand new Craftisian Build Plan Marketplalce - and perhaps do some last minute gift shopping that would also su...

I forgot to mention it, but the previous day, one step I did is make sure I had enough veneer tape on the roses. Sometimes I go too short and they...

Help with my Makita 4" Belt Sander issue please!

I don't use my old Makita 4" Belt Sander all that much these days but needed to us it last wee...

.jpg)