Bentlyj

in almost 12 years

Typical Stuff In The Shop #7: Repair Work

This is

part 7

in a

18 part

series:

Typical Stuff In The Shop

The door that opened for the TV to come out had warped. I'll let you figure out why. Here is the door.

The cabinet had finger jointed carcass, so replacing the top really wasn't an option.

My idea was to put on a whole new top over the existing and recessing the edges in about 3/4" so that the top would look like it was stepped up and the finger joints could still show.

It also only had some kind of oil finish that was rough and dull so I also suggested going over it with some,

yes you guessed it, pre cat lacquer. :)

Here are the results:

I'm now building them a Host Station.

Figuring out how to do something you have never done is what makes a good challenge.

16 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Figuring out how to do something you have never done is what makes a good challenge.

Is the secondary wood pine?

--Nathan, TX. Hire the lazy man. He may not do as much work but that's because he will find a better way.

I don't think I'm going to have a problem with movement, with it being so dry here it's never been a problem, so I have my fingers crossed, we'll see though.

The wood on the original door had oak glued to the walnut.

Figuring out how to do something you have never done is what makes a good challenge.

Main Street to the Mountains

Did you consider planing down the oak backer (and maybe some of the walnut too) and replacing the removed material with something more stable (like MDF with walnut veneer on the underside)? Or do you think that would have ended up warping too?

No, I didn't actually think of that Ron. That might have worked, but it was pretty warped and cupped.

I did think about planing it down though. Figured I would have to take off too much.

I didn't want to waste time to see IF I could fix it, or not.

Plus, I can make more money doing the new top, and I knew it would be good to go. :)

Figuring out how to do something you have never done is what makes a good challenge.

Very nice work and fix.

Petey

I'm now building them a Host Station.

Have to finish lacquering the adj. shelves, then it will be on wheels that I need to put on.

No doors.

Figuring out how to do something you have never done is what makes a good challenge.

Figuring out how to do something you have never done is what makes a good challenge.

Main Street to the Mountains

It's kicking my butt, for something so simple.

When I was edge banding the bottom edge, I didn't take into account the little register roller that rides along the top,

(it registers the beginning and end of the panel) and sends a signal for the guillotine to cut banding flush with the front and back ends. Unfortunately, the wheel registered on every slot and tried to dig holes into the walnut panel.

@ approx. 180 bucks a sheet for walnut,

I wasn't going to go buy another sheet.

So I cut the damaged part off the panel and glued on a new piece (that I edge banned before hand.)

Unfortunately, (for various reasons/excuses), I didn't get the parts flush enough and when I was sanding it was too much to take off without sanding through the veneer. So, off to get a new sheet.... Nope,

cut that bad part off again and started over with adding the new strip.

And here it is in the picture. All looks good and I think there will be no problems sanding tomorrow.

Lately it seems like I make more mistakes on the easy stuff. I guess I'm not giving it as much attention as I need to.

I have to try harder.

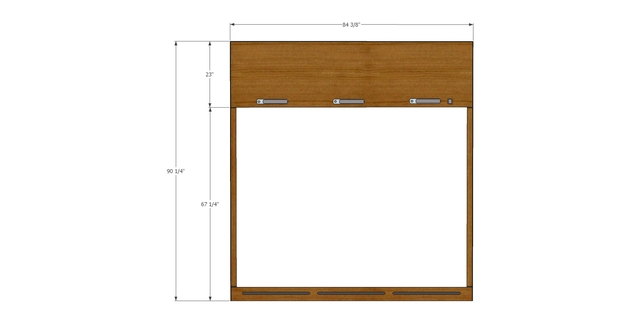

Here is a rough SU of the whole frame.

Figuring out how to do something you have never done is what makes a good challenge.

.jpg)