awsum55

in about 3 years

More from awsum55

Only took a couple of months. ;-)

I moved this over from the other place.

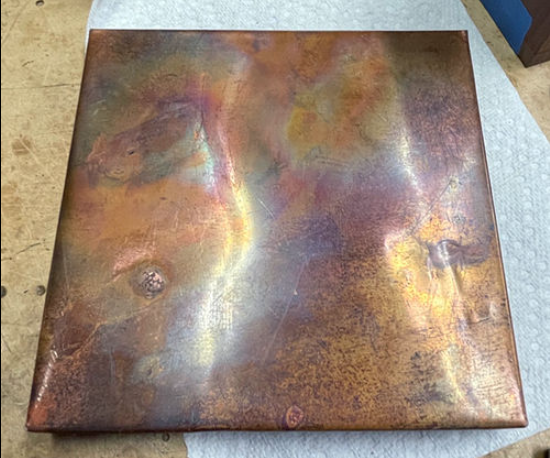

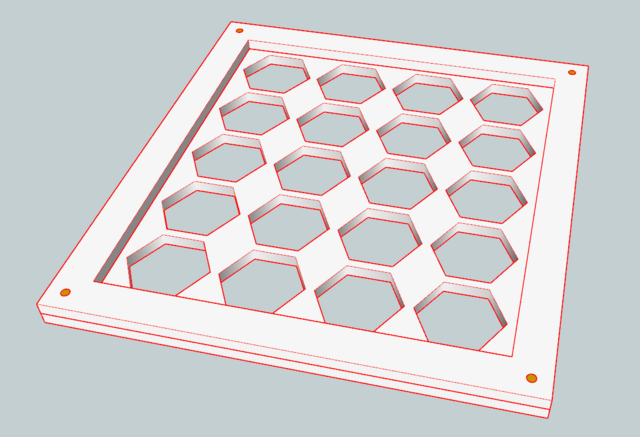

A couple of months ago I purchased a laser and have been having some fun playing with it. A friend of mine asked if I would make a box for his father who happens to be a bee keeper. I was excited to see what was possible to accomplish with the laser and jumped right in.

.................. John D....................

15 Comments

TimV, "The understanding eye sees the maker's fingerprints, they are evident in every detail, leave Fingerprints." James Krenov

Ron

Main Street to the Mountains

Truly personalized 😀

Cheers, Jim ........................ Variety is the spice of life...............Learn something new every day

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

(I feel nearly as bad a D_W with his acorns)... but I think it's a tad better than 👍👍👍 for a great job.

Nice combo of woodying and lasering.

Two things if I may add:

areas I was going to glue, I was afraid it might come apart over time. To prevent this I used toothpicks to also dowel everything together.

Suggest using CA glue over shellacked spots... I haven't tried it, however, I often pre buff (heavy wax) and I don't worry about glue lines as the CA seems to have held well... well, well for the last 2 years.

so I used a router to thin the wood from the inside

and the char can be scraped/sanded off, although it does have a good effect. The toothpicks are ideal for alignment.

BYW... would have looked bigger if you used metric.

If your first cut is too short... Take the second cut from the longer end... LBD

Ant man and myself have been considering building the out of my pallet timber

Something as flash as that here would encourage some bastard to steal it on us

Very impressive just the same but we would have to sit shotgun on it 24/7!

Regards Rob

*TONY ** Denver * ALWAYS REMEMBER TO HAVE FUN

CtL

Portablepastimes.com "Purveyors of Portable Fun and Fidgets"

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

Alex, thanks for the tip, I didn't think of that.

.................. John D....................

...woodicted