Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

After completing all the boring sanding of the individual panels, I started to glue-up some sub-assemblies. Breaking-up the assembly into multipl...

Pulling back the curtain reveals a hideous sight. Strewn cables, dust bunnies, an ethernet switch, missing wall plates, etc. Some really nasty st...

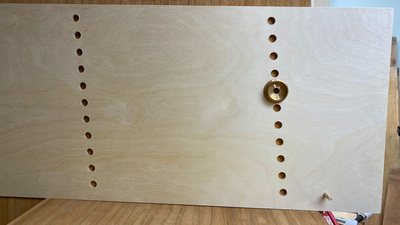

The adjustable shelves will rest on the usual shelf pins. All of the shelves will be the same size with indents on the underside to index the shel...

I found that the izombe is a little fragile on crosscuts with some chipping/flaking, even with the tracksaw on the MFT. I assumed (but didn't conf...

With oversized lengths of veneer cut an jointed, I started work on joining the veneer pieces together in pairs to get the width needed. I'd need 1...

I needed a few things before I could start veneering the panels:

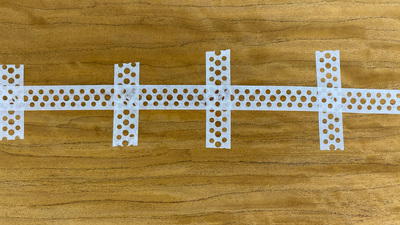

• A jig to joint the edges of the veneer

• A vacuum bag for the panels

• Some plat...

A number of years ago, I turned this narrow wall into a home for the TV, components, and speakers. I didn't have a cabinet/console that would fit ...

Except not "finished." I should say, it's functional.

I did the test lacing with the chair on the floor. That was a bit hard on my back. I got ...

With all the last minute shaping and sanding complete, everything was ready for the final glue-up. There's not really a whole lot to show here. I...

My last pair of blanks are for the armrests. I started by planing them down to 5/8" thick, which is the final thickness for rear of the armrest. ...

There were a couple things I wanted to verify before the final glue-up:

• Could I keep the paracord lacing tight enough so that it would support a ...

With the mortises complete, I put a 1/8" edge round-over on most of the parts and sanded them all smooth. It's easier to get this done prior to as...