Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

Free Retrofit Puzzle Box Plans

Part 1: Liquor Box Puzzle Plans

[Windy 1.png][Windy 2.png][Windy 3.png][Windy 4.png][Windy 5.png][Windy 6.png][Windy 7.png]

Urban Ore

Part 33: Tool Engineers Handbook

For $2, acquired a new book. What a book it is. Measures over 3” thick printed on vellum. I estimate over 1,000 pages. Printed in 1959.

[IMG_8840....

Part 34: Record 77 Spare Iron

For $1, picked up this new-in-package plane blade. Lord only knows how old it is. When was the last time Marples was in business. Also, looks to be...

Part 35: Stanley 04-421 “Silken” Hole Cutter

A rare find. Some collectors passed it around and it came to me. I knew it was a hole cutter, but I didn’t know about this variant. Usually the piv...

New Supercell DC for My Shop

Part 1: Designing a mobile cart.

Background:

A couple of years ago, I found a basic Delta 1 HP dust collector that someone was throwing away. It was in good condition and had t...

Part 2: Making a Cart

As I mentioned in part 1, I based my cart design around a a Sketchup model I found on their 3D Marketplace. Once the Supercell arrived and before...

Part 3: Shop Vac Hose Reel Auto Rewind Mechanism

It has been a while. Maybe a little off topic for a Supercell titled blog but sort of the next step in improving dust collection in my shop. The ...

Restorations

Part 8: Edlund Commercial 5-lb Premier Scale

Found this at Urban Ore for $5 — I bought it because I needed a scale to weigh various wood working projects. For no other reason than to be able t...

Part 9: Millers Falls No 98 T-bevel gauge

Purchased from eBay for $35.71 (broken down as $26.99 + tax & shipping), a 1950’s sliding bevel gauge (T-bevel) made by Millers Falls, tool No 98.

...

Part 10: Eye carving riffler

I have decided that this stone carving riffler is for carving eyes. The two ends combined, one effectively cuts the upper eyelid shape and the othe...

A collection of Clamps.

Part 27: Dovetail Clamps.

[IMG_0720.png]

Boy and Girls,

I primarily use these type of clamps with my tracksaw, however, before yazall mutiny and accuse me of Fe$too...

Part 28: Stanley quick Clamp/Vise.

[Untitled-1.png]

Boy and Girls,

I’m quickly running out of clamps (that I own), however, while many may refer to this as a vise, I often ...

Part 29: Rockler Auto-Lock T-Track Clamp.

[IMG_2099.png]

Boy and Girls,

(Consider this as a 2* review.)

When I posted my Auto Adjust Clamps, I deliberately avoided mentioning this pa...

Making Dowels

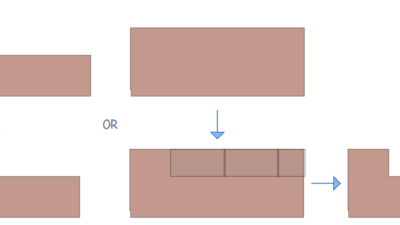

Part 6: Router Method

There are two ways of making dowel on the router. Using a fence and round over bit or a jig /die setup similar to the Table Saw method.

USING A ...

Part 7: My Current Method

My current method is using my Dowel Maker . Please follow this link and feel free to make comments.

Stock is cut just slightly larger than what y...

Part 8: Conclusion - Which is the best IMO

Here are the methods of making dowel

1. Drill and push through steel flat bar

2. Hammering through a holed plate

3. The Chisel Method

4. able saw ...

Vises

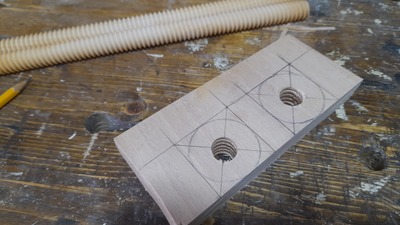

Part 6: Hi Vise - Body

I'm making the body out of an ash 2x4.

so cut to size and square up.

[20230915_162313.jpg]

[20230915_163836.jpg]

Drill and tap the main hole

[20230...

Part 7: Hi Vise - Finish

Make the handles for the fixing screws.

[20231001_160522.jpg]

[20231001_161419.jpg]

Just rasp into shape and add a bit of walnut to the end to hi...

Part 8: Mini Hi-Vise version 2

Well, the mini vice mount Hi-Vice gets pretty much constant use, so it’s time to make a nicer one based on the prototype.

Pretty happy with the ...

Handy Tools

Part 1: Skew carving gouge

While working on the Altai Project Logo carving, I discovered I needed a narrow skew in order to get down into some of the corners. I have a handfu...

Part 2: Handle for LAP engraving tool

I bought a Lost Art Press engraving tool a while back. The short metal handle works fine for putting it into a compass, but for freehand use, it’s ...

Part 3: Sharpening shelf for sharpening carving gouges

A while ago, I read Dave Fisher’s post on his Souped-up Sharpening Shelf and thought that sounded like a great idea to get some consistency in my g...

Replacing a Chair Back Molding

Part 1: Let's do this the hard way -- Designing for the CNC

My sister asked me if I would be interested in repairing the back of a barstool. The stool is metal but has (had) a piece of wood molding on the b...

Part 2: Wood prep and milling on the CNC

A couple of years before my sister asked me to make a new chairback molding. I had collected the trunk of a dead redbud tree from her yard with th...

3-Arm Kerfing Plane

Part 6: Open letter to Brent Hull

I sent an e-mail to someone that I admire. He responded, which is amazing. His response was short and sweet:

Good stuff!

Thanks for sharing.

B

...

Part 7: Little details

These are words I tell myself in the throes of the process:

Any fool can put something together. It takes a special kind of fool to design somethi...

Part 8: Blade cover

My town has a store that only sells imported Japanese hand tools. I only recently heard about it this year, but I wouldn’t doubt it if it has been ...