Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

Urn building

Part 9: Working on the base for the second urn

After discussing the base with my "client" (my husband), I'm going with a combination of maple with the walnut I had left from the project. This w...

Part 10: Attaching the bases

Decided I should take the last step to screw the base to the box to make sure that worked OK. Good idea as it did not go as planned...sigh...

For...

Butterfly Cabinet

Part 6: Building the Drawers

[10.00 Drawer Details.jpg]

The drawer boxes were easy to build. I made them from 12 mm Baltic birch plywood. I prefinished the insides with poly, ...

Part 7: Adding Door Details

[11.00 Door Details.jpg]

Earlier, I had cut the doors to size and drilled the hinge cup holes. Before I could apply finish and add the brass disk...

Part 8: Blog Post 8: Completing the Doors (and the Project)

Now it was time to work on the brass disk wing disks. Each disk would fit into a shallow (about 0.04” deep) 5/8” diameter well.

Before proceeding,...

Fun With CNC

Part 1: Background and Kickoff - Why are we here exactly?

A Little about me

Being sort of a retired nerd, I spent my career doing mostly finance related I/T, I have always gravitated towards technical stuf...

Part 2: CAD to CNC Machine Workflow

EDIT: I change the name to reflect the actual purpose of the post

Let's Make Some Boxes

So we all make boxes, right. There are all kinds. Fancy...

Laser Tile Etching With Titanium Dioxide

Part 1: Trying a few tests for the process

I made some trivets with simple images on the cheap home center plain white tiles in another project.

[IMG_8376.jpeg]

Simply put, this black on th...

Part 2: Prepping for Photographs

Well, yes! You can use the Ti02 on tile and transfer a photograph over.

I personally haven't seriously tried to do this but I have seen pictures o...

Part 3: Some grey-scale line art

So it has been a while!

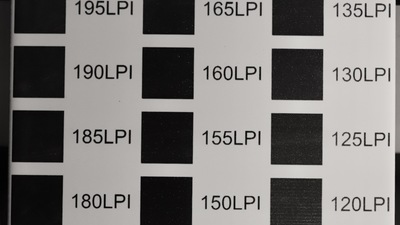

For a while now I've been using a free, on-line software called ImageR for getting settings near perfect for etching onto ...

Bugout_Boy’s Speargun Project

Part 1: Speargun 101, Design & Function

In order to explain my own speargun project, it makes sense to provide some context on speargun designs first.

[Image]

Spearguns, used for huntin...

Bugout_Boy’s Lathe Projects

Part 1: Lathe, Love, Or Loathe? A crazy entry to woodturning.

I’m brand new to wood lathes and woodturning. The journey that led me to getting one was about as strange as possible. I’m going to use this openin...

Hans Wegner's "Bukkestolen"

Part 19: Fixing my Mistake

After a day to contemplate the error of my ways, I set to removing the finish from the top of the arms in order to sand the scratches. I spent som...

Part 20: Weaving a Backrest

A fresh 10lb spool arrived at the end of last week, and I got started making good use of it. I wrap the spool in stretch wrap and pull the loose...

Part 21: Completing a Chair

Before I started weaving the backrest, I made a final check on the cords-per-inch with the actual cord I would be using. It turns out my original...

Misc. Shop Stuff

Part 5: The No 1 Stanley Odd-Jobs

Let's explore the No. 1 Stanley Odd-Jobs! There are at least three 'types' out there, mostly differentiated by scribe type (earliest ones could ho...

Part 6: Family Tools!

NOTE: Repost from another web locatation to preserve the memory...

In November of 2012 I went to see my Aunt and Uncle over the weekend, and came...

Part 7: In Consideration of Folding 'Zig Zag' Rulers

Double post from another blog topic, but wanted to put it somewhere I could readily add to later. Here goes!

A very incomplete review of folding ...

Folding Work Table and Storage Bracket

Part 6: Finishing and Final Assembly

Because the tables will reside in an unheated garage, I decided to finish all surfaces with three coats of water-based poly (General Finishes High ...

Part 7: Storage Bracket

[01.09 Folding Work Table Mounting Bracket.jpg]

A section of the wall on the front side of the garage was just the right size for the tables. I ...

Things go wrong

Part 1: Pen blanks gone wrong

A while ago I poured some epoxy over cholla canes to make some pen blanks. But the epoxy went exothermic and made enough of a mess that I thought a...