Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

Traditional Portuguese Rajao

Part 10: Soundboard finished and installed

Fitted the braces and reinforcing ring to the inside of the soundboard.

[IMG_2648.jpeg][IMG_2650.jpeg]

Fitted the soundboard to the body. I suppose...

Part 11: Odds-n-Ends

Taking care of the other details now that the main assembly is complete.

Added the binding at the soundboard. Started out as 1 x 5mm Black Walnut. ...

Shop storage

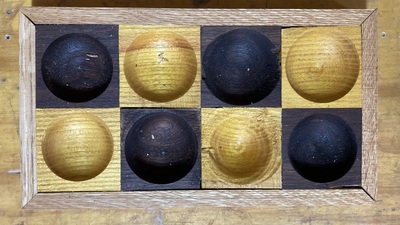

Part 4: Box clamps box

Another storage box, this time from ¼ inch poplar and Baltic birch ply for the top. Treated (this morning) with kakishibu, which darkens with expos...

Part 5: Small parts organizer

[IMG_7711.jpeg]

Just a quick and dirty project to use up some smalls and keep this organized when I’m doing something like this morning’s bench gl...

Part 6: Things fall down 2

My cheap-ass Harbor Freight dust collector has picked up a bit of a vibration. Enough so that last Sunday, it vibrated itself right off the French ...

Shaper Origin

Part 1: Chair Seat

The neighbor restores furniture and sells it at fairs. She picked up some ratty rattan chairs where the webbing was gone.

I said I could make her ...

Jigs

Part 1: Bandsaw Cork Cutting Jig

This is a tutorial on making a simple jig for cutting wine corks in half, along their length.

The jig requires only simple scraps to build and is...

14” Rockwell Bandsaw

Part 1: Initial testing

Before testing I took the covers off. Tires were pretty gummed up. So I grabbed my Red Devil scraper and spun the wheels while holding the scraper ...

Part 2: Replacement trunnion knob

It’s clear in retrospect looking at the initial photos of it in the salvage yard, taken moments after arrival that it was always missing one of the...

MacBeath

Part 1: Introduction

MacBeath is a chain. They sell hardwood lumber, and other things associated with fine furniture (including tools, both hand and power).

I buy lumb...

Part 2: White Wenge

Not a typo. White Wenge. Arrived about 3 weeks ago

[IMG_7389.jpeg][IMG_7388.jpeg]

Part 3: Red Zebrawood

Also, not a typo. Red Zebrawood. Just came in.

[IMG_7391.jpeg][IMG_7390.jpeg]

No, I don’t work there. I just go in a lot.

This is interesting but...

PAST Tool Collectors

Part 7: Single-lipped countersink brace bit

Another item from the Half Moon Bay meetup of PAST Tool Collectors.

This was free. As I was paying for the countersink bits, I spied it on the tab...

Create a series

Part 2: Follow up series

In the first screen select "Choose from the existing ones", and in the drop down menu, select the series you wan't to add it to

[New blog entry -...

Spinnekop

Part 36: Painting and some other small jobs

Giving the head a fist layer of green paint, some small details will be white.

[20230915_180208.jpg][20240518_121518.jpg]

And a first coat for the ...

Cabinet for Tea Bag Holders

Part 9: The Base - The part with a Hundred Cuts (Well not that many)

This is probably the most involved piece in the project (yes, even more than the doors). If you refer back to the first part in this blog you will ...

Part 10: Inserts for doors

There are a lot of little pieces in this entry!

I started with the half circles - largest one first. Since this spalted maple can be fragile I p...

Part 11: Finishing touches

Since this cabinet is so small I ended up buying some artists brushes for oil paints.

[image.png]

They really helped with the application of the...