shipwright

in almost 12 years

Easy Elegant Integral Hinge

I could kick myself

The early bird gets the worm but its the second mouse that gets the cheese.

17 Comments

working with my hands is a joy,it gives me a sense of fulfillment,somthing so many seek and so few find.-SAM MALOOF.

The early bird gets the worm but its the second mouse that gets the cheese.

Main Street to the Mountains

The early bird gets the worm but its the second mouse that gets the cheese.

The early bird gets the worm but its the second mouse that gets the cheese.

Ryan/// ~sigh~ I blew up another bowl. Moke told me "I made the inside bigger than the outside".

Makes me think of the same method, but leaving the lower hinge wing to join up with the boxes back (half lap, spline?)

Then the pin could be installed before putting on the lid.

(I always hate trying to install small bits to conceal a cut unless I have easy access for a hammer 8^)

Easily beats dealing with standard box hinge installs and looks so much better!

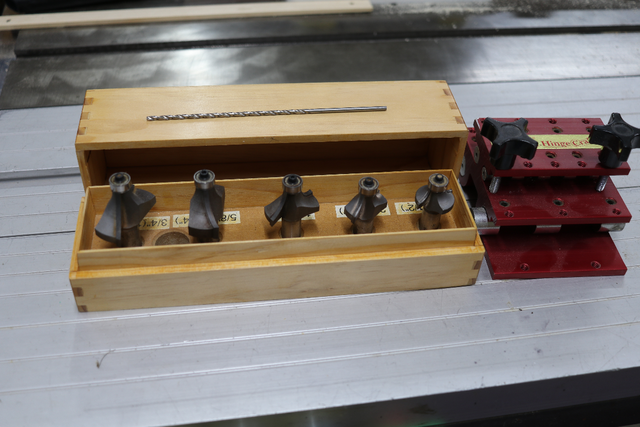

In the past, my boxing gloves included these in the padding,

however, the creations possible were governed by the length of the 3mm (1/8") drill bit... and I've busted a few in the past.

This concept is just brilliant... why didn't you post this 5 years ago?

Thanks for sharing and thanks for the SU model... I run 2018, but at least I can download the Collada format.

If your first cut is too short... Take the second cut from the longer end... LBD

This concept is just brilliant... why didn't you post this 5 years ago?

Actually I posted it first 12 years ago.

…long ago in a place far away ….

The early bird gets the worm but its the second mouse that gets the cheese.

I didn't get it under my finger nails though!

Regards Rob

Main Street to the Mountains

May I add my hinge I made Jun 2013 its effectively a movable finger joint with a Japanese skewer for a hinge pin!

The early bird gets the worm but its the second mouse that gets the cheese.