Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

How I Sharpen

Part 4: V Tool - Part 2

I intended to do this all in one entry but I ran into a bit of a dilemma. The tool I'm working with is an Ashley Iles 60 degree, 1/2" inch tool wi...

Part 5: A Hook Knife for Spoon Carving

This one isn't exactly on sharpening but it does have to do with using abrasives on a tool blade so I thought I'd throw it in here. This is a copy...

Part 6: Knives with Power Sharpener

Haven't had a chance to get back to carving tools but I had a couple pocket knives that needed a refresh this weekend so I thought it would be wort...

Shop Dust Collection

Part 1: PVC Dust Collection System for a Supercell

Rather than drag the 4" hose around from machine to machine for my Oneida Supercell I decided to install a 4" PVC dust collection system. The 4" h...

Making Another Shop

Part 1: Better Late Than Never to Start a Blog

I've been AWOL for almost a year. Like a lot of other folks, I migrated over here from the other wood working forum a year or so back. About the...

Part 2: Finish Details

I'm going to start off by admitting I'm guilty of procrastinating on getting this posted. I kept telling thinking of one more thing that I wanted ...

A Pair of Side Tables

Part 7: The Fumigator

Ok. Here is the primary reason I'm building these side tables.

Plans were to keep the tables stupid-simple to avoid any drama. I violated my goal ...

Part 8: It takes some steel nuts to do this.

[IMG_9043.jpeg]

Best laid plans.....

Anyhoo, busy weekend with car work so I couldn't get as far as intended (finish applied), but wait, there's m...

Part 9: This is the End.

Apologies to the Doors!

[IMG_0165.jpeg]

Finally the finish has been sprayed.

Base coat is Mohawk vinyl sealer, top coat satin pre-cat lacquer.

Pr...

VW Logo Blank

Part 6: Outer Ring Blanks

The outer ring is made up of 4 blanks. The first one is shown below.

[image.png]

The blank is a rectangle in cross section with a trough cut do...

Part 7: Fitting the Outer Ring Blanks

I had put steps on each side of the outer ring blanks. These steps were to be used to have a reference surface parallel to the trough axis. But af...

Part 8: Final Turning

This last step is pretty straightforward – especially compared to the previous steps. I just need to get a cylinder that looks good.

First I d...

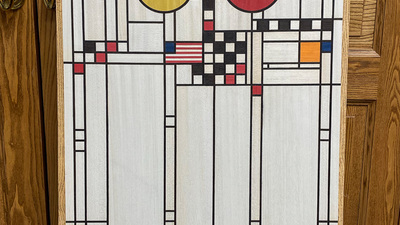

Parquetry in a Stained Glass Pattern

Part 10: Hot off the Press

After 4.5 hrs in the press, this is what greeted me when I pulled-out the panel. At first I thought the ripples were the result of too much glue, ...

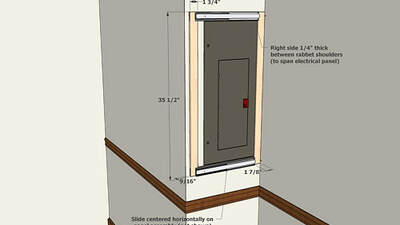

Sliding Modular Display Shelf

Part 7: Building the Mounting Bracket and Attaching the Drawer Slides

[03.05 Design - Mounting Bracket.jpg]

Theoretically, I could mount the drawer slides directly to the wall above and below the breaker box and attac...

Part 8: Adding a Stiffening Brace

When I “finished” the project two months ago, I noticed that the panel face was very slightly concave. Here, I’ve placed a 36” long straight edge ...

Part 9: Installation

I installed the shelf in my daughter’s house last week. I knew I had measured, and re-measured the wall and electrical panel the last time I was t...

Military Retirement Shadowbox

Part 5: Making Progress

When I left off, I had the case members cut, box joints cut and the case dry fit. Next up was the plywood back. I cut it the first piece to lengt...

Part 6: Running Down to the Wire... As Usual

Seems like no matter when I start a project it never gets done before it has to... Progress has been slow the past couple weeks. One weekend we h...

Part 7: Final Stages

I got the bulk of the work finished up this weekend. I started with a dry fit of the case and then used it to cut the door members to length. The...

Media Cabinet

Part 16: Odds and Ends

Here are some progress photos on some miscellaneous bits.

I did do a test with edge-to-edge magnets. They did pretty well self-aligning, and they...

Part 17: Drawer Pull

For the drawer pull, I decided on a simple edge-mounted design. I wanted it to be black to match the legs, and to avoid another round of ebonizing...

CNNP Sheoak Coasters

Part 3: Polishing my Wood

Now here is some interesting information for you the interesting indented growth rings are commonly referred to as Hazelwood.

This unusual characte...

Part 4: my attempt to be a "shipwright"

Then look I had disillusionary thoughts after seeing some of shipwrights work I could replicate a table.

Its the same table I attempted to "copy" ...

Part 5: CNNP Coaster meet the CBHS Table

OK after making template to use for inserting the She-Oak into the table top I removed the clamps and continued.

[IMG_3153.JPG]

I used a stand off...