Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

Sash Windows - journey into the unknown

Part 9: I knew I should have used oil based paint

Not that it really matters, the hopelessly optimistic completion date of mid October for the windows has been and gone, and there's still a way to ...

Part 10: Glazing Part 1

Back onto the windows at last, got nothing done in December, I am now looking at Easter as a deadline to have them ready to be fitted.

From the ou...

Part 11: Why didn't I think of that before #738 & #739

This weekends first 'why didn't I think of that before moment' came when I was setting up the router to do the beadings and glazing bars.

That was...

Singer Base Desk

Part 2: Mesquite Top

Needing a small desk for guest area (Airbnb) that is vintage decor. Reclaiming a cast singer treadle for the base.[image.jpg]

During our trip to Te...

Laser basket weave from veneer

Part 1: Intro Blabbering

[IMG_8902.jpeg]

I did this pattern before as one of my first stabs at cutting veneer with my laser. This time I was going to better document the p...

Part 2: Making the cuts

[IMG_8875.jpeg]

For this project, I chose some walnut and Burmese teak. The teak has some great chatoyance, a big color shift as you view it from ...

Part 3: Building the Design

[IMG_8886.jpeg]

Ok, time to decide on how you plan to attach the assembly to something to give it a life.

I use a vacuum bag for veneering. That ...

VW BULLY T1 Camper van

Part 18: VW Bulli T1, Wheels

This phoVto serie is about making a VW bully camper van T1

[Image]

The plan for making this model you can find at my website.

Enjoy reading and ...

Part 19: VW Bulli T1, Roof

This photo serie is about making a VW bully camper van T1

[Image]

The plan for making this model you can find at my website.

Enjoy reading and k...

Part 20: VW Bulli T1, Pack rack

This photo serie is about making a VW bully camper van T1

[Image]

The plan for making this model you can find at my website.

Enjoy reading and k...

Performax 16/32 Jack Screw Repair

Part 1: Preventative Maintenance

This is my baby, most used tool in the shop behind the table saw.

[IMG_8839.jpeg]

When I first started using it, I was undewhelmed with what it c...

The Journey of a Kayak Build

Part 1: A little about the project

I have wanted to build a Kayak for some time now, and I finally have a shop that I can build in. I have spent a few years reading up on boat buildi...

Part 2: A Little Prep Work

I decided to start off with a little prep for this build and make a few samples.

The Kayak will be built with an Internal frame which consist of f...

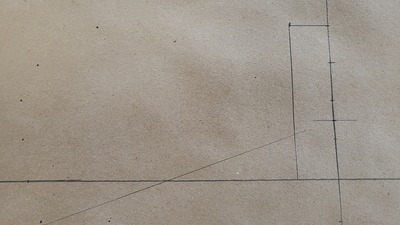

Part 3: The Lofting Process

Definition for those who I lost. Lofting is taking a set of numbers which are included in a Table of Offset. These numbers define the shape of the ...

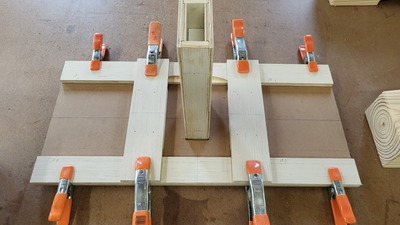

Segment Gluing Jig.

Part 2: The Mechanical Parts

Had to work out some the functions on this build her:

1) A secure verticle post.

2) A bar with a stop block

3) A indexing system

4) A locking syste...

Part 3: Details of a Clamping System

I will back up a bit to start. This is what the bottom of the post looks like.I will be able to lock it in place to the layout line.

[20230815_192...

Part 4: Some finishing touches

Back at it this evening finally, other stuff to be done around the house and errands.

I did a little sanding on the interior pieces and glued up t...

Building the Art Deco Box

Part 2: Begin With a Simple Box Core

[IMG_8736.jpeg]

Had a section of rough 4/4 cherry that had been kicking around for a while so I could see the color it would take on once the woo...

Part 3: Separate the Lid and Give It Some Legs

[IMG_8742.jpeg]

With the box glue-up dry, time to create the lid by sawing open the box.

I installed a thin kerf rip blade and set the cut depth ...

Part 4: Trim & Trays

Almost done, I swear!

With only legs, the box looks bottom heavy.

A few passes on the router table will make some trim to fix this.

[IMG_0033.jp...

Around the shop

Part 2: My Infill builds

Edit: this was originally pointed to the defunked wkfinetools website. I’ve updated to point to my site. Making an infill plane has been on my list...

Part 3: 3 legged walnut table

I’ve been asked to make this piece of walnut a 3 legged side table 24” tall.

I have an idea of how I’d attach the legs but looking for alternativ...

Part 4: Shop Made Router Table and Router Lift Restoration

I made this router lift over ten years ago. It started out in an old Craftsman Table saw.

[Image]

[Image]

[Image]

It then went into the top of th...