Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

Building a High Vise

Part 3: Drilling Holes

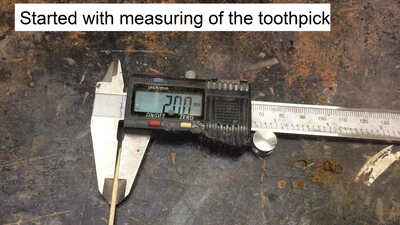

Received the Acme Threads for this project. I did not want to drill any holes until I had them in hand to measure for the clearance needed.

I set ...

Part 4: Shaping the Jaws

Removed the clamps and everything looked good, had to scrap some glue excess off.

The first thing up was to cut the curves at the top and bottom o...

Part 5: Lathe Work, Handle

This is where I made a few adjustments to the plans.

The plans called for a 1-1/2" steel pipe (no luck sourcing anything local) I did have a few ...

Journey into Timber Framing techniques.

Part 4: Cross Brace Tenons.

tuned up the other mortise and tenons so I didn't have to use a lot of force to fit everything together.

Then I was able to get a good measurement...

Part 5: Shaping Feet and Top

Up next was to cut the waste area from the bottom of the feet, leaving a small pad on each end. When I was drill out the waste for the mortise I dr...

Part 6: Gluing up the Pieces

I had to think the process through, since I wanted to use the drill press, the wrong way would have meant drilling by hand, and I may have drifted....

Another Danish Modern Chair

Part 9: Final Glue-Up

With all the last minute shaping and sanding complete, everything was ready for the final glue-up. There's not really a whole lot to show here. I...

Rat Rod Truck

Part 1: Rat Rod Truck for Marcus

I have started the Instagram #offcuts only challenge put up by Mark Dainer, a maker from Townsville.

Thank you to Dean & Francine of Living Timbe...

Excavator tracks

Part 5: Drilling holes

Serie of making the tracks for the excavator.

[01.jpg][02.jpg][03.jpg][04.jpg][05.jpg][06.jpg][07.jpg][08.jpg][09.jpg]

Milling lumber

Part 2: Milling juniper

I got some juniper a while back from Sycamoray. Been slowly working through it, milling it into flat boards, mostly between 1/2 and 1/4 inch thick ...

Screw it, by hand...

Part 1: Introduction

Boys and Girls,

If this topic gets your juices flowing, after watching this video,

the title may be on your lips as the included link at Taylor...

Sawbench/Mini Workbench

Part 4: Wagon Vice

Make the wagon vice.

Chunk of willow for the screw.

[20230309_153403.jpg]

Square it up and leave it overnight in case it wants to warp at all.

[20...

Part 6: Box for the Rounding Plane

OK, so I needed to make a box for the rounding plane, as I seem to have run out of flat surfaces to dump stuff on.

Nothing fancy, just a basic box....

Wegner-Inspired Deck Chair

Part 9: Seat Frame Mounting

The rear edge of the seat frame has 4 loose tenons glued in place. The protruding tenons dry fit into corresponding mortises in the rear stretcher...