Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

Woodworking This & That

Part 1: Woodworking Tools

A friend of mine is in the process of going through, selling, and discarding everything from her grandparents’ “3 generation farm”.

Can you imagi...

My journey into chair making

Part 1: Getting started

I am going on an adventure into the world of chair making. I have always wanted to build a windsor chair. I am starting out making a dining chair i...

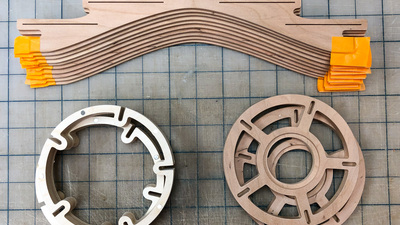

More Veneer Pendant Lamps

Part 7: A slightly rocky assembly

Installing the veneer strips didn't quite go as planned. My initial idea was to apply a little contact cement to hold the overlapped end in place. ...

Part 8: Rinse and Repeat

With the prototype complete, I assembled the remaining two lamps.

[20200201-IMG_3503.jpg]

[20200202-IMG_3511.jpg]

[20200202-IMG_3512.jpg]

The bot...

Sewing Supplies Cabinet with Inlaid Metal Tile Accents

Part 4: Door Construction

The doors are 3/4" maple plywood slabs with 1/2" wide solid maple trim and inlaid tiles and accent strips. They were by far the most difficult part...

Part 5: (Adventures in) Finishing

My wife wanted a light/whitish finish for the cabinet. Maple is pretty light toned, so my first thought was to use a clear water-based poly finish...

Part 6: Final Door Assembly and Mounting

Few parts of this project went smoothly, and the final door assembly was no exception.

It started well enough. Attaching the outer trim wasn't too...

A Handplane Rehab

Part 4: Some Hardware Stuff

Man, it's been a while! I've had so little shop time lately and none of it has been unspoken for, so rehabbing this plane hasn't been on the agenda...

Part 5: Tote Repair

I fully intended to do the tote repair and the refinishing of the tote and knob in one post but shop time has been scarce so I'm going to just go a...

Part 6: Stick a Fork in it!

Well, a mere 6 months after starting this series, I'm finally ready to wrap it up…

So let's dive right in! When last I left off, I had finished re...

Nail (Screw) Cabinet

Part 4: Drawer Fronts vs Drawers

When we left off (last December!), the internal dividers had been set on this piece and I was debating adding the external framing that's been comp...

Part 5: Hardware & Glue-up

So I pushed one of the unfinished drawers into it's place in the cabinet and couldn't get it out without help. And that help was installation of a ...

Part 6: Final Assembly

Okay. In the last installment I noted that a glued up drawer front / sides piece went kinda 'parallelogram' on me overnight. To affect a repair, I ...

Japanese Joinery Rabbit Hole

Part 1: Playing in the Shop

My last big project introduced me to 18th century European joinery and really got me hooked on the idea of more complex assemblies that are locked ...

Part 2: “Trick” Joinery

There appear to be two kinds of joints to be found among the Japanese Joinery videos available. One is the structurally elegant locking type that I...

The classic one

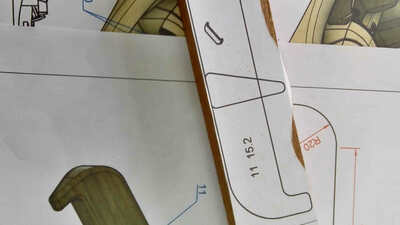

Part 13: Windscreen

This is a blog of making a classic car. I hope you will enjoy it. Questions and comments are more than welcome.

There is also a breakdown vid made...

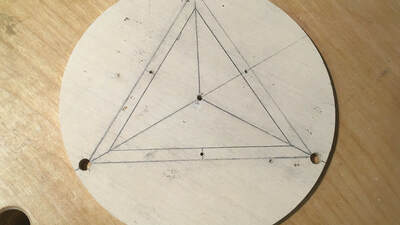

Mini Tetrahedral Tensegrity Table Details

Part 8: Disk Details--Attaching the Outer Support Wires

Before I could apply finish to the disks and attach the pyramids, I had to iron out the details of how to attach the three outer support wires.

Th...

Part 9: Finishing the Disks and Attaching the Pyramids

I wanted to use glue to attach the pyramids to the disks, because I didn't want any visible fasteners. But it was very apparent that I would need ...

Part 10: Tensioning the Wires and Completing the Project

At this point, the moment of truth had arrived. It was time to attach the tensioning wires and hope they didn't tear the pyramids apart or result ...