Share your craft projects

Make new craft buddies

Ask craft questions

Blog your craft journey

Blog Series

Wegner inspired dining chair series

Part 4: Much more prototyping

Summer is over and work, my business and life in gerneral have taken almost all my time. And my chair project have slowed down considerable. But in...

Part 5: Seat weaving and finishing up

Last time we ended up here:

[Image]

In the mean time i have been busy researching on methods of weaving seats. Lots of designs to consider... B...

Part 6: And then the final, real chairs

This whole series have all the time evolved around making a set of dining chairs out of two large slabs of European elm that was saved at my mother...

Giraffe Bookcase

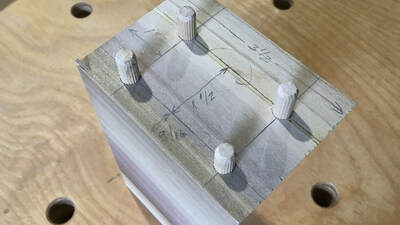

Part 7: Gluing the Case

The glue-up part of a project is always nerve-wracking for me, and this project was no exception. Dowel joinery helps a lot, but it doesn't totall...

Part 8: Attaching the Legs

The final woodworking step was attaching the legs to the case.

As with everything else, I used dowels. The front legs were straightforward. I used...

Celtic Mandolin

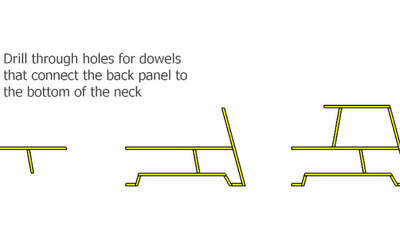

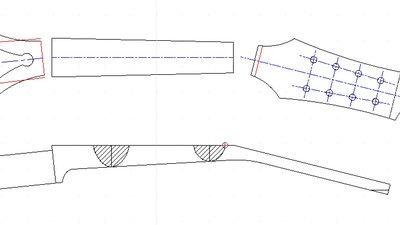

Part 11: Started the mandolin design

Started design on QCad. [40098C9E-87A0-4304-9D8E-8F575AAD49E1.jpeg]Neck and head design. Started thinking about the cutting sequence for the neck.

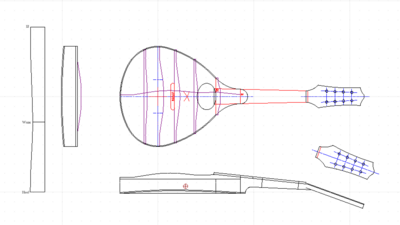

Part 12: Almost finished with the overall design

Almost finished with the overall design. Need to verify the tuner spacing when I get them. Then I'll start cutting templates with the laser.

[Scree...

Part 13: Some Templates

Fired up the laser to cut out the first templates for the mandolin today. The body template determines the overall shape of the body, the drill loc...

Danish Cord Bench

Part 4: Shaping, Sanding, and Glue-up

The leg edges and leg stretchers received a fingernail profile. This was done with a 1/2" radius roundover bit in the router table. Note my slig...

Part 5: Weaving the Warp

Once I completed the final sanding and prepped according to instructions, I applied Rubio's Monocote Pure to the frame. It was my first experience...

Part 6: Weaving the Weft and Done

The weft weaving starts in one corner, attaching the a doubled cord (roughly 120ft length folded in half) at its center onto a side rail. This is ...

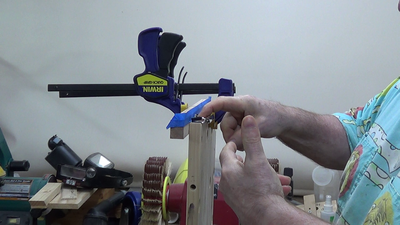

Coping/Turning Saw

Part 3: Fit the handles to the frame

Work out what angle the handles should go in at. Not quite 90 degrees because of the slight curve from crossbar to where the handles go.

[20210104_...

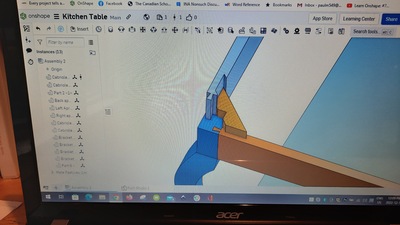

French Country Table

Part 1: Designing and Joinery

This year’s winter project is a new kitchen table. The beater we have is having trouble living next to the new dog food cabinet beside it.

Our whol...

Part 2: Veneering the Base

Well, I said I would post again when the veneering was done. It took a little longer than I expected because I decided to add a little marquetry to...

Part 3: Done for Now

Just a quick update to show the top in place and the installation in the kitchen by the 18C dog food cabinet. It will live here under a tablecloth ...

8 Drawer Beaded Face Frame Cupboard Construction

Part 6: BFFC Day 6

this blog has been a few days to completion mainly due to too hot outside or other Higher priority tasks overtaking it

I carved all the drawer fro...

Part 7: BFFC Day 7

Well most of the progress has slowed somewhat.

First up :- My custom trolley as promised. (Edit opps cannot find the pictures just now!)

Its for ...

Part 8: The double radius trim to complete the BFFC

You may have seen the preparation involved to construct the Double radius feature at the back of the cabinet top.

Here it is sitting in place.

[IMG...

Wooden Model Making

Part 1: Power Wagon

When I first saw the Power Wagon I just knew that some time or other I would be giving it a try.

[IMG_3611.JPG]

[IMG_3613.JPG][IMG_3614.JPG]

[T&...

Part 2: 1911 Delivery Truck

1911 delivery truck

I found some cool old plans to play with so trying the 1911 Brush Delivery Truck'

I've built this style truck before but a m...

Techniques & Tricks

Part 1: Homemade veneer softener

I needed some veneer softener, so I went looking on the Internet and I found this recipe at Highland Woodworking. Perfect, but my local pharmacy do...

Part 2: Punched metal decoration

I’m not certain yet how it’s going to look when done, but I experimented a bit with punched metal this morning.

I printed this photo on a piece of...